Cane Sugar Refining - Purolite

Cane Sugar Refining - Purolite

Cane Sugar Refining - Purolite

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

21<br />

<strong>Cane</strong> <strong>Sugar</strong> <strong>Refining</strong> with Ion Exchange Resins<br />

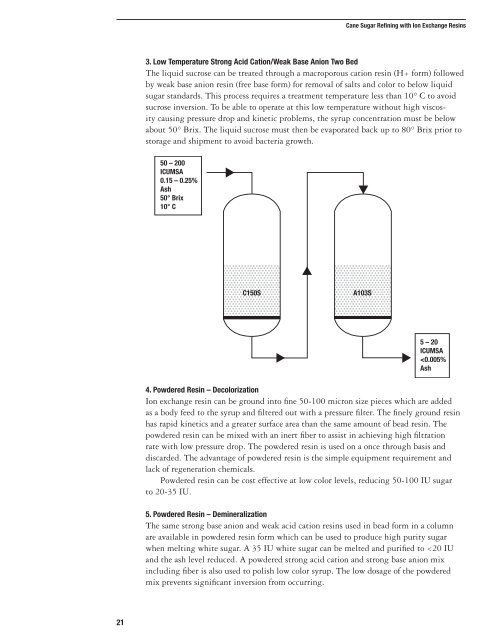

3. Low Temperature Strong Acid Cation/Weak Base Anion Two Bed<br />

The liquid sucrose can be treated through a macroporous cation resin (H+ form) followed<br />

by weak base anion resin (free base form) for removal of salts and color to below liquid<br />

sugar standards. This process requires a treatment temperature less than 10° C to avoid<br />

sucrose inversion. To be able to operate at this low temperature without high viscosity<br />

causing pressure drop and kinetic problems, the syrup concentration must be below<br />

about 50° Brix. The liquid sucrose must then be evaporated back up to 80° Brix prior to<br />

storage and shipment to avoid bacteria growth.<br />

50 – 200<br />

ICUMSA<br />

0.15 – 0.25%<br />

Ash<br />

50° Brix<br />

10° C<br />

C150S<br />

A103S<br />

5 – 20<br />

ICUMSA<br />