Cane Sugar Refining - Purolite

Cane Sugar Refining - Purolite

Cane Sugar Refining - Purolite

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Cane</strong> <strong>Sugar</strong> <strong>Refining</strong> with Ion Exchange Resins<br />

20<br />

PSI/Ft bed depth<br />

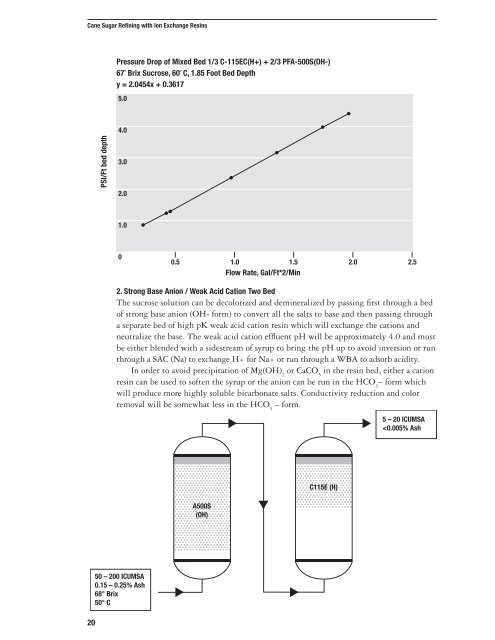

Pressure Drop of Mixed Bed 1/3 C-115EC(H+) + 2/3 PFA-500S(OH-)<br />

67˚ Brix Sucrose, 60˚ C, 1.85 Foot Bed Depth<br />

y = 2.0454x + 0.3617<br />

5.0<br />

4.0<br />

3.0<br />

2.0<br />

1.0<br />

0<br />

0.5 1.0 1.5 2.0 2.5<br />

Flow Rate, Gal/Ft*2/Min<br />

2. Strong Base Anion / Weak Acid Cation Two Bed<br />

The sucrose solution can be decolorized and demineralized by passing first through a bed<br />

of strong base anion (OH- form) to convert all the salts to base and then passing through<br />

a separate bed of high pK weak acid cation resin which will exchange the cations and<br />

neutralize the base. The weak acid cation effluent pH will be approximately 4.0 and must<br />

be either blended with a sidestream of syrup to bring the pH up to avoid inversion or run<br />

through a SAC (Na) to exchange H+ for Na+ or run through a WBA to adsorb acidity.<br />

In order to avoid precipitation of Mg(OH) 2 or CaCO 3 in the resin bed, either a cation<br />

resin can be used to soften the syrup or the anion can be run in the HCO 3 – form which<br />

will produce more highly soluble bicarbonate salts. Conductivity reduction and color<br />

removal will be somewhat less in the HCO 3 – form.<br />

50 – 200 ICUMSA<br />

0.15 – 0.25% Ash<br />

68° Brix<br />

50° C<br />

A500S<br />

(OH)<br />

C115E (H)<br />

5 – 20 ICUMSA<br />