Waterproofing Systems - DR. FIXIT

Waterproofing Systems - DR. FIXIT

Waterproofing Systems - DR. FIXIT

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Basement waterproofing/<br />

damp-proofing<br />

SHaLLoW BaSEMENTS - WaTERPRooFING<br />

IN low wAter tAble AreAs<br />

AlterNAtIVelY,<br />

Dr. Fixit SamShielD<br />

xl 1500 / 2100<br />

Methodology SBWP 10 Methodology<br />

Surface Preparation<br />

The surface shall be cleaned thoroughly<br />

of all contaminants like dust, traces of<br />

curing compound, oil and grease. All surface<br />

imperfections, protrusions, structurally<br />

unsound and loose concrete must be removed<br />

and repaired with polymer modified mortar<br />

using Dr. Fixit Pidicrete URP.<br />

Priming<br />

Apply Dr. Fixit Torchshield Primer to clean,<br />

smooth and dry surface by brush or roller.<br />

Allow the primer to dry prior to the application<br />

of the Dr. Fixit Samshield XL.<br />

Application on PCC below the raft slab<br />

Peel off the release film from the Dr. Fixit<br />

Samshield XL self adhesive side and start<br />

unrolling the membrane and press it to the<br />

surface.<br />

Smoothen the membrane from the center<br />

to the edges with a wooden press in order to<br />

remove entrapped air.<br />

Furthermore, an iron roller shall be used for<br />

rolling on top of the applied membrane to<br />

ensure a proper and strong adhesion of the<br />

bitumen compound with the base.<br />

A 50 mm selvedge is provided on one side of<br />

the membrane to give bitumen to bitumen<br />

contact on the overlaps.<br />

Lay geotextile membrane of 120 gsm as a<br />

protection layer over the Dr. Fixit Samshield<br />

XL membrane.<br />

System Life<br />

Expectancy<br />

of 10 years<br />

A screed of 50 mm must be overlaid in M<br />

20 concrete grade, which will facilitate the<br />

reinforcement cage to be assembled, for the<br />

RCC raft to be cast over it.<br />

A swell able, adhesive strip waterbar of 20 mm<br />

X 20 mm, Dr. Fixit Waterbar SW 2020 shall<br />

be provided in the construction joints, which<br />

is placed on the inside of the reinforcement, in<br />

both the raft concrete floor & the side retaining<br />

concrete walls.<br />

Application on vertical surfaces<br />

Make angle fillets all around the corners of<br />

the raft and the retaining wall. Make the fillets<br />

with polymer modified mortar prepared with<br />

Dr. Fixit Pidicrete URP.<br />

Take care to chamfer all the edges of screed<br />

and raft slab to facilitate the membrane to<br />

move over it.<br />

Dr. Fixit Samshield XL membrane must be<br />

applied starting with the sides of the raft<br />

and will go right up to the top of the external<br />

wall face and terminated there, appropriately<br />

with C-Shaped Aluminium flashing strip or by<br />

tucking it into the concrete wall of a groove<br />

of 12 mm X 12 mm. In case of the groove, the<br />

aluminium flashing can be fitted to press the<br />

membrane into the groove and then be filled<br />

with a single component Dr. Fixit PU Sealant.<br />

Place bituminous protection boards over the<br />

Dr. Fixit Samshield XL membrane before<br />

backfilling.<br />

Dr. Fixit Samshield Dr. Fixit PU Sealant Dr. Fixit Waterbar Dr. Fixit Pidicrete URP<br />

Self adhesive bituminous<br />

membrane<br />

one part non-sag polyurethane<br />

sealant<br />

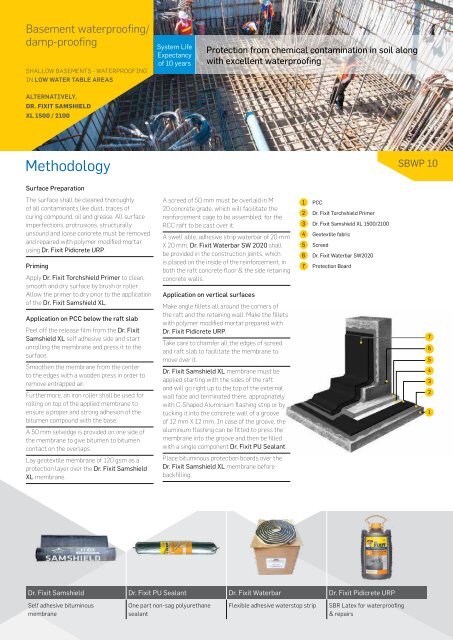

Protection from chemical contamination in soil along<br />

with excellent waterproofing<br />

1 PCC<br />

2 Dr. Fixit Torchshield Primer<br />

3 Dr. Fixit Samshield XL 1500/2100<br />

4 Geotextile fabric<br />

5 Screed<br />

6 Dr. Fixit Waterbar SW2020<br />

7 Protection Board<br />

Flexible adhesive waterstop strip SBR Latex for waterproofing<br />

& repairs<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

Basement waterproofing<br />

DEEP BaSEMENTS – WaTERPRooFING IN<br />

hIgh wAter tAble AreAs<br />

Dr. Fixit torchShielD<br />

SP 4160 (SBS)<br />

in double layer<br />

Surface Preparation<br />

The surface shall be cleaned thoroughly<br />

of all contaminants like dust, traces of<br />

curing compound, oil and grease. All surface<br />

imperfections, protrusions, structurally<br />

unsound and loose concrete must be removed<br />

and repaired with polymer modified mortar<br />

using Dr. Fixit Pidicrete URP.<br />

Priming<br />

All over the blinding concrete or PCC that is<br />

properly leveled, Dr. Fixit Torchshield Primer<br />

priming shall be done with a roller or brush,<br />

over a dried surface. Allow the primer to dry<br />

for 8 to 10 hrs.<br />

Application on PCC below the raft slab<br />

Dr. Fixit Torchshield SP 4160, a SBS based<br />

polyester reinforced membrane, shall be laid<br />

by providing an overlap of at least 100 mm.<br />

A 2nd layer of SBS based membrane Dr. Fixit<br />

Torchshield SP 4160 shall be laid with an<br />

overlap 50 % above the 1st layer.<br />

Torchshield membrane Dr. Fixit Torchshield<br />

SP 4160, shall be extended to maximum<br />

extent of the full area of the blinding concrete.<br />

Lay geotextile membrane of 120 gsm as a<br />

protection layer over the Dr. Fixit Torchshield<br />

SP 4160 membrane.<br />

A screed of 50 mm must be overlaid in M<br />

20 concrete grade, which will facilitate the<br />

reinforcement cage to be assembled, for the<br />

RCC raft to be cast over it.<br />

A swellable, adhesive strip waterbar of 20 mm<br />

X 20 mm, Dr. Fixit Waterbar SW 2020 shall<br />

be provided in the construction joints, which<br />

System Life<br />

Expectancy<br />

of 10 years<br />

8<br />

7<br />

1 PCC<br />

2 Primer<br />

3 Dr. Fixit Torchshield SP4160 (2 layers)<br />

4 Geotextile<br />

5 Screed<br />

6 Dr. Fixit Waterbar SW2020<br />

7 Angle Filet<br />

8 Protection board<br />

Dr. Fixit Torchshield Dr. Fixit Waterbar Dr. Fixit PU Sealant Dr. Fixit Pidicrete URP<br />

aPP / SBS modified bitumen<br />

based membrane<br />

is placed on the inside of the reinforcement, in<br />

both the raft concrete floor & the side retaining<br />

concrete walls.<br />

Application on vertical surfaces<br />

Over the RCC raft, the side retaining walls are<br />

cast in concrete.<br />

Prepare the retaining wall surface to receive<br />

waterproofing system as detailed in surface<br />

preparation above.<br />

After the application of primer and drying it, 2<br />

layers of Dr. Fixit Torchshield SP 4160, a SBS<br />

based polyester reinforced membrane shall<br />

be laid.<br />

A 4 mm thick bituminous protection board or<br />

a HDPE dimpled drain board (12 mm thick)<br />

shall be placed, vertically over the Torchshield<br />

membrane, allowing the soil backfill.<br />

As the activity goes upward, the application<br />

of Dr. Fixit Torchshield membrane, along<br />

with the protection system shall be carried<br />

out minimum 300 mm above the ground level<br />

or as per finished floor level, with C-Shaped<br />

Aluminium flashing strip or by tucking it into<br />

the concrete wall of a groove of 12 mm X 12<br />

mm. In case of the groove, the aluminium<br />

flashing can be fitted to press the membrane<br />

into the groove and then be filled with a single<br />

component Dr. Fixit PU Sealant.<br />

AlterNAtIVelY<br />

Robust tanking system for high performance<br />

basement waterproofing<br />

Dr. Fixit Torchshield AP 4160 (APP)<br />

membrane in two layers can be used in place<br />

of Dr. Fixit Torchshield SP 4160<br />

Flexible adhesive waterstop strip one part non-sag polyurethane<br />

sealant<br />

SBR Latex for waterproofing &<br />

repairs<br />

DBWP 10<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

11 11