- Page 1: MODEL BASED CONTROL OPTIMISATION OF

- Page 4 and 5: IV ABSTRACT - For optimised control

- Page 6 and 7: ACKNOWLEDGEMENTS VI ACKNOWLEDGEMENT

- Page 8 and 9: TABLE OF CONTENT VIII TABLE OF CONT

- Page 10 and 11: X TABLE OF CONTENT 4.5 ANALYSIS AND

- Page 12 and 13: XII TABLE OF CONTENT 6.2 MODEL BASE

- Page 14 and 15: NOMENCLATURE Latin letters A [m²]

- Page 16 and 17: Greek Letters α [W/m² K] heat tra

- Page 18 and 19: wb wet bulb Abbreviations ACM Absor

- Page 20 and 21: Page - 2 - CHAPTER 01 a thermal coo

- Page 22 and 23: Page - 4 - CHAPTER 01 explains the

- Page 24 and 25: Page - 6 - CHAPTER 01 The concept o

- Page 26 and 27: Page - 8 - CHAPTER 01 Mean calculat

- Page 28 and 29: Page - 10 - CHAPTER 01 analysed in

- Page 30 and 31: 2. MODEL DEVELOPMENT FOR SOLAR COOL

- Page 32 and 33: Page - 14 - CHAPTER 02 In the prese

- Page 34 and 35: Page - 16 - CHAPTER 02 Within chapt

- Page 36 and 37: Page - 18 - CHAPTER 02 b) Simple on

- Page 38 and 39: Page - 20 - CHAPTER 02 is off. For

- Page 40 and 41: Page - 22 - CHAPTER 02 Since only s

- Page 42 and 43: Page - 24 - CHAPTER 02 negative eff

- Page 44 and 45: 2.2.1.4 Tubing Page - 26 - CHAPTER

- Page 46 and 47: tube fl fl tube tubel Page - 28 - C

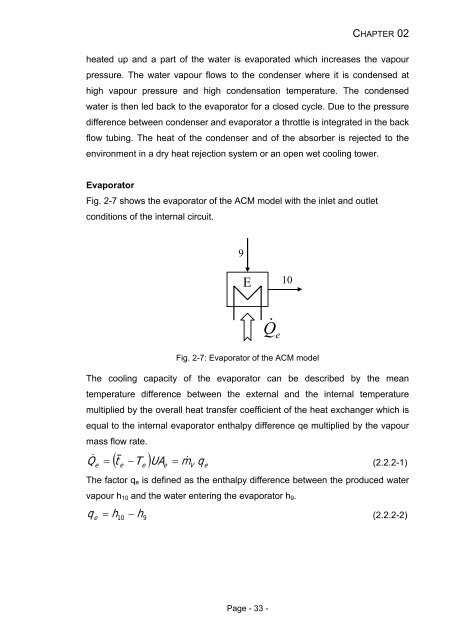

- Page 48 and 49: Temperature / °C 90 80 70 60 50 40

- Page 52 and 53: Page - 34 - CHAPTER 02 The enthalpy

- Page 54 and 55: Page - 36 - CHAPTER 02 With: Heat l

- Page 56 and 57: Page - 38 - CHAPTER 02 The so calle

- Page 58 and 59: Page - 40 - CHAPTER 02 To further i

- Page 60 and 61: Page - 42 - CHAPTER 02 2.2.2.2 Para

- Page 62 and 63: e e Page - 44 - CHAPTER 02 The char

- Page 64 and 65: Page - 46 - CHAPTER 02 and chapter

- Page 66 and 67: Model for the dynamic parts of the

- Page 68 and 69: - Absorber/Condenser Q g _ ac & & Q

- Page 70 and 71: Page - 52 - CHAPTER 02 cross sectio

- Page 72 and 73: Page - 54 - CHAPTER 02 conditions l

- Page 74 and 75: With: tw,in tw,out twb Water inlet

- Page 76 and 77: l min m& = m& a w = c ( h − h ) a

- Page 78 and 79: Page - 60 - CHAPTER 02 If the cooli

- Page 80 and 81: Page - 62 - CHAPTER 02 As already d

- Page 82 and 83: Page - 64 - CHAPTER 02 only very fe

- Page 84 and 85: Page - 66 - CHAPTER 02 rejection sy

- Page 86 and 87: Page - 68 - CHAPTER 02 and the UA v

- Page 88 and 89: Page - 70 - CHAPTER 02 different ve

- Page 90 and 91: Page - 72 - CHAPTER 02 −4 −2 2

- Page 92 and 93: Page - 74 - CHAPTER 02 Fig. 2-25: M

- Page 94 and 95: Page - 76 - CHAPTER 02 difference i

- Page 96 and 97: Page - 78 - CHAPTER 02 In this quit

- Page 98 and 99: - Absorbed solar energy Gt , a t a

- Page 100 and 101:

CHAPTER 02 Page - 82 - a b a r a a

- Page 102 and 103:

Page - 84 - CHAPTER 02 The area rel

- Page 104 and 105:

Page - 86 - CHAPTER 03 conditions.

- Page 106 and 107:

Page - 88 - CHAPTER 03 was calculat

- Page 108 and 109:

Page - 90 - CHAPTER 03 The same bui

- Page 110 and 111:

Page - 92 - CHAPTER 03 The specific

- Page 112 and 113:

Cooling / Heating power / kW 50 40

- Page 114 and 115:

Page - 96 - CHAPTER 03 As visible f

- Page 116 and 117:

3.4.2 SOLAR THERMAL SYSTEM MODELS P

- Page 118 and 119:

Page - 100 - CHAPTER 03 generator i

- Page 120 and 121:

m² kW-1 m² kW-1 Page - 102 - CHAP

- Page 122 and 123:

Page - 104 - CHAPTER 03 Fig. 3-16:

- Page 124 and 125:

Page - 106 - CHAPTER 03 m 2 kW -1 s

- Page 126 and 127:

Page - 108 - CHAPTER 03 Fig. 3-20:

- Page 128 and 129:

a f N d ( 1 + d ) ( 1 + d ) − 1 P

- Page 130 and 131:

Page - 112 - CHAPTER 03 costs Csola

- Page 132 and 133:

Page - 114 - CHAPTER 03 Fig. 3-26:

- Page 134 and 135:

Page - 116 - CHAPTER 03 The total a

- Page 136 and 137:

Page - 118 - CHAPTER 04 4. Model Ba

- Page 138 and 139:

Page - 120 - CHAPTER 04 Germany. De

- Page 140 and 141:

Page - 122 - CHAPTER 04 Fig. 4-2: A

- Page 142 and 143:

Page - 124 - CHAPTER 04 4.3.2 SYSTE

- Page 144 and 145:

Page - 126 - CHAPTER 04 temperature

- Page 146 and 147:

Page - 128 - CHAPTER 04 System part

- Page 148 and 149:

Page - 130 - CHAPTER 04 performance

- Page 150 and 151:

Fig. 4-5: Measured and simulated pe

- Page 152 and 153:

Page - 134 - CHAPTER 04 An addition

- Page 154 and 155:

Fig. 4-6: Annual electricity consum

- Page 156 and 157:

Page - 138 - CHAPTER 04 The values

- Page 158 and 159:

Page - 140 - CHAPTER 04 EAW WERACAL

- Page 160 and 161:

4.4.6 CONCLUSIONS Page - 142 - CHAP

- Page 162 and 163:

Page - 144 - CHAPTER 04 4.5 Analysi

- Page 164 and 165:

4.5.2 SIMULATION MODEL AND VALIDATI

- Page 166 and 167:

Page - 148 - CHAPTER 04 the start u

- Page 168 and 169:

Table 4-4: Analysed storage charge

- Page 170 and 171:

4.5.5 RESULTS AND DISCUSSION 4.5.5.

- Page 172 and 173:

Page - 154 - CHAPTER 04 Although co

- Page 174 and 175:

Page - 156 - CHAPTER 04 At 09:10am

- Page 176 and 177:

Fig. 4-16: Detailed simulation resu

- Page 178 and 179:

Fig. 4-17: Detailed simulation resu

- Page 180 and 181:

Page - 162 - CHAPTER 04 The thermal

- Page 182 and 183:

Page - 164 - CHAPTER 04 Table 4-7:

- Page 184 and 185:

4.5.6 CONCLUSIONS Page - 166 - CHAP

- Page 186 and 187:

Page - 168 - CHAPTER 04 considered

- Page 188 and 189:

Page - 170 - CHAPTER 05 5. MODEL BA

- Page 190 and 191:

Page - 172 - CHAPTER 05 optimised s

- Page 192 and 193:

Page - 174 - CHAPTER 05 The electri

- Page 194 and 195:

Page - 176 - CHAPTER 05 Table 5-2:

- Page 196 and 197:

5.3.2 DESCRIPTION OF THE CONTROL SY

- Page 198 and 199:

Page - 180 - CHAPTER 05 The time se

- Page 200 and 201:

Page - 182 - CHAPTER 05 Table 5-5:

- Page 202 and 203:

5.3.4 ROOM UTILISATION Page - 184 -

- Page 204 and 205:

P 3 3 2 2 2 1 1 ⎟ 1 1 ⎟ ⎛ n

- Page 206 and 207:

Page - 188 - CHAPTER 05 dehumidific

- Page 208 and 209:

Page - 190 - CHAPTER 05 The high ab

- Page 210 and 211:

5.4.3 RETURN AIR HUMIDIFIER Page -

- Page 212 and 213:

5.4.4 SUPPLY AIR HUMIDIFIER Page -

- Page 214 and 215:

Relative humidity / Error / % 120 1

- Page 216 and 217:

Page - 198 - CHAPTER 05 Fig. 5-20:

- Page 218 and 219:

Fig. 5-22: Detailed view into the r

- Page 220 and 221:

Page - 202 - CHAPTER 05 simplificat

- Page 222 and 223:

Page - 204 - CHAPTER 05 The relativ

- Page 224 and 225:

Page - 206 - CHAPTER 05 Table 5-9:

- Page 226 and 227:

Cooling power / kW . 14 12 10 8 6 4

- Page 228 and 229:

Page - 210 - CHAPTER 05 only slight

- Page 230 and 231:

t ⎛ ⎜ 1 u ( t ) = K p ⎜ e ( t

- Page 232 and 233:

5.6.2 PE-OPTIMISER (ONLINE TOOL) Pa

- Page 234 and 235:

Tr9, xr9 Fig. 5-30: System scheme w

- Page 236 and 237:

h h x s 3, max s 3, max max, s 3 =

- Page 238 and 239:

Page - 220 - CHAPTER 05 the supply

- Page 240 and 241:

Page - 222 - CHAPTER 05 humidificat

- Page 242 and 243:

Page - 224 - CHAPTER 05 case 4 the

- Page 244 and 245:

Page - 226 - CHAPTER 05 Case 4: Ele

- Page 246 and 247:

Page - 228 - CHAPTER 05 shows a sta

- Page 248 and 249:

Fig. 5-40: Distribution of the DEC

- Page 250 and 251:

Page - 232 - CHAPTER 05 the operati

- Page 252 and 253:

5.8.2 DETAILED PERFORMANCE COMPARIS

- Page 254 and 255:

Page - 236 - CHAPTER 05 The perform

- Page 256 and 257:

Page - 238 - CHAPTER 05 The advance

- Page 258 and 259:

Page - 240 - CHAPTER 05 regarded da

- Page 260 and 261:

Page - 242 - CHAPTER 05 After the b

- Page 262 and 263:

Page - 244 - CHAPTER 05 the DEC sys

- Page 264 and 265:

Page - 246 - CHAPTER 05 Fig. 5-50:

- Page 266 and 267:

5.9 CONCLUSIONS Page - 248 - CHAPTE

- Page 268 and 269:

Page - 250 - CHAPTER 05 to compete

- Page 270 and 271:

6.1 SOLAR DRIVEN CLOSED ABSORPTION

- Page 272 and 273:

Page - 254 - CHAPTER 06 6.1.2 MODEL

- Page 274 and 275:

Page - 256 - CHAPTER 06 more coolin

- Page 276 and 277:

considered and compared: Page - 258

- Page 278 and 279:

7. CONCLUSIONS AND OUTLOOK 7.1 SOLA

- Page 280 and 281:

Page - 262 - CHAPTER 07 Apart from

- Page 282 and 283:

Page - 264 - CHAPTER 07 7.2 PRIMARY

- Page 284 and 285:

Page - 266 - CHAPTER 07 therefore b

- Page 286 and 287:

REFERENCES Page - 268 - REFERENCES

- Page 288 and 289:

Page - 270 - REFERENCES Park, C., D

- Page 290 and 291:

OWN PUBLICATIONS Page - 272 - OWN P

- Page 292 and 293:

MODEL DEVELOPMENT 1. ABSORPTION CHI

- Page 294 and 295:

With these simplifications we get:

- Page 296 and 297:

− t + t E E 9 ⋅ K U Z + t U Z +

- Page 298 and 299:

4 4 ⎛ i ⎞ t LiBr ( X , p s ) =

- Page 300 and 301:

APPENDIX A: MODEL DEVELOPMENT Page

- Page 302 and 303:

APPENDIX A: MODEL DEVELOPMENT Page

- Page 304 and 305:

APPENDIX A: MODEL DEVELOPMENT Page

- Page 306 and 307:

C) Absorber/Condenser Q g _ ac & &

- Page 308 and 309:

APPENDIX A: MODEL DEVELOPMENT Page

- Page 310 and 311:

Page - 292 - APPENDIX A: MODEL DEVE

- Page 312 and 313:

Page - 294 - APPENDIX A: MODEL DEVE

- Page 314 and 315:

Electric power [kW] 0,4 0,35 0,3 0,

- Page 316 and 317:

Water consumption [kg/h] 350 300 25

- Page 318 and 319:

Technical Data of the Axima Wet Coo

- Page 320 and 321:

5. SOLAR COLLECTORS APPENDIX B: SOL

- Page 322 and 323:

APPENDIX B: SOLAR COOLING SYSTEM 7.

- Page 324 and 325:

3. Cold Storage Tank APPENDIX B: SO

- Page 326 and 327:

Case 2: Full storage with bypass De

- Page 328 and 329:

APPENDIX C: OPTIMISED CONTROL SEQUE

- Page 330 and 331:

APPENDIX D: DETAILED SIMULATION RES

- Page 332 and 333:

APPENDIX D: DETAILED SIMULATION RES

- Page 334 and 335:

APPENDIX D: DETAILED SIMULATION RES

- Page 336 and 337:

Module Number 20 2P100 21 2P100 22