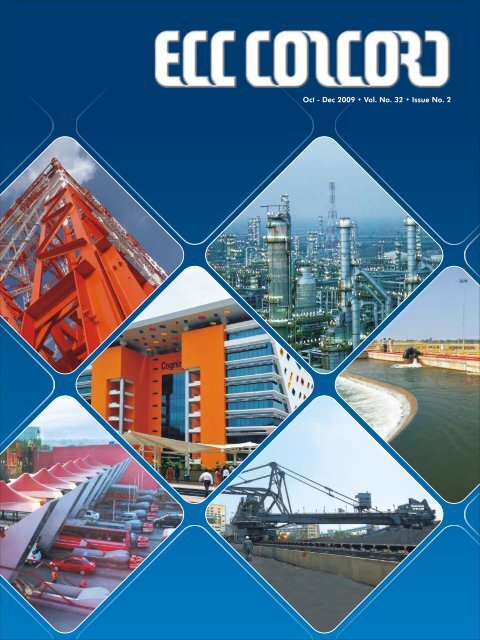

Oct - Dec 2009 • Vol. No. 32 Issue No. 2 • - L&T Construction

Oct - Dec 2009 • Vol. No. 32 Issue No. 2 • - L&T Construction

Oct - Dec 2009 • Vol. No. 32 Issue No. 2 • - L&T Construction

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Oct</strong> - <strong>Dec</strong> <strong>2009</strong> <strong>•</strong> <strong>Vol</strong>. <strong>No</strong>. <strong>32</strong> <strong>•</strong><br />

<strong>Issue</strong> <strong>No</strong>. 2

Focus<br />

‘There is nothing permanent in this world and change is<br />

the only constant thing in life. These are some of the<br />

famous axioms, well known to every one of us. We also<br />

know that only change brings about progress. In tune<br />

with these quotes, we have been witnessing rapid<br />

changes and major transformations in the style, function<br />

and operations of ECC. What was functioning as a<br />

cohesive unitary Division, ECC was split into four<br />

Operating Companies (OCs) due to the process of<br />

verticalisation introduced a couple of years back.<br />

Significant organizational changes have taken place<br />

since then and each OC is now evolving itself as an<br />

independent company with its own new strategies,<br />

business segments, departments, people, leadership<br />

and management.<br />

Realizing the importance of all these changes and with a<br />

view to keep track of the communication challenges in<br />

each OC, ECC Concord is making a paradigm shift.<br />

Shift from the conventional practice of covering one<br />

particular theme or matters relating to one particular BU<br />

or Segment to a combination of multi-OC project<br />

information. We will henceforth bring out articles and<br />

write-ups pertaining to four different OCs in order to<br />

preserve the interest of every OC. From the table of<br />

contents printed along side, you will find the<br />

representation of projects from all four OCs.<br />

We hope that this will stimulate and enthrall the young<br />

minds about their own remarkable achievements amidst<br />

several other organisational matters of day-to-day<br />

importance.<br />

We also hope that you will find this mix interesting and<br />

useful. Wish you all happy reading.<br />

Editor<br />

Editor<br />

Editorial team<br />

Photography<br />

Design & layout<br />

: V. S. Ramana<br />

: K. Sridharan | Alex Benjamin<br />

: V. Ramesh Kumar | Gopi Kannan. S<br />

: V. Eswar | Ashwin Chand | Mayura. K<br />

Subha Anand<br />

: V.S. Natanavelu<br />

: Global Print Design, Chennai<br />

In this issue<br />

<strong>Oct</strong> - <strong>Dec</strong> <strong>2009</strong> <strong>•</strong> <strong>Vol</strong>. <strong>No</strong>. <strong>32</strong> <strong>•</strong> <strong>Issue</strong> <strong>No</strong>. 2<br />

Buildings and Factories<br />

The power of binary ............................................. 3<br />

L&T brings IT to Vijayawada ................................. 9<br />

L&T leads with green .......................................... 12<br />

Infrastructure<br />

Vadodara – Bharuch superway ........................... 16<br />

Metallurgical, Mineral Handling & Water<br />

Water to Pink City .............................................. 20<br />

CHP at Bakreswar .............................................. 28<br />

CHP at Vindhyachal STPP Phase 3 ...................... 34<br />

Electrical and Gulf Projects<br />

India's largest transmission line testing centre ...... 38<br />

Apricot towers at Dubai ...................................... 41<br />

Ranchi substation ............................................... 43<br />

E&I at Reliance – Jamnagar ................................ 46<br />

Rural load management ..................................... 49<br />

Kaliedoscope<br />

Inauguration .................................................. 51<br />

Orders .......................................................... 55<br />

Events ............................................................ 57<br />

CSR ............................................................... 60<br />

Awards .......................................................... 64<br />

Printed by Lokavani Southern Printers Pvt. Ltd., Chennai. Edited by Mr. V.S. Ramana for Larsen & Toubro Limited – ECC Division, from<br />

ECC-HQ, Manapakkam, Chennai 600089. The views expressed in this magazine are not necessarily those of the management of<br />

Larsen & Toubro. The contents of this magazine should not be reproduced without the written consent of the editor.

The Power of Binary<br />

or over six decades, the <strong>Construction</strong> Division architects has been exclusively working for internal<br />

of L&T has been creating landmark structures clients and were handling projects promoted by L&T<br />

Fthat dot the skylines of cities both inland and like Deloitte, Cyber Pearl and many other IT Park<br />

abroad. Every ECC construction is a judicious blend Projects.<br />

of aesthetics and utility, heritage and modernity that When Cognizant Technology Solutions (CTS) floated a<br />

testify to ECC’s touch of class as a contractor par<br />

Rs.550 Cr. worth tender for their IT Campus at MEPZ,<br />

excellence in project execution.<br />

Chennai, L&T decided to pitch for the design-and-build<br />

The inviting architecture<br />

Engineering Design & Research Consultancy (EDRC)<br />

– the design arm of ECC has exclusive team of<br />

Engineers and Architects, who facilitate the design<br />

and support the construction activity.<br />

project with its in-house architectural concepts.<br />

The team<br />

Initially, people with complementary skills, with a<br />

go-getter attitude formed a team. Strategies were<br />

worked out after compelling rigorous sessions.<br />

Even though EDRC has been outsourcing Each team member was asked to come up with as<br />

architectural design concepts for commercial / office many ideas and concepts. The final concept<br />

buildings for many years, a small team of in-house emerged from the ideas thus generated.<br />

Illuminated view of the software park of Cognizant Technology at MEPZ, near Chennai

ECC Concord <strong>Oct</strong>-<strong>Dec</strong> 09 4<br />

When IT revolution emerged in India, lots of IT Parks intangible. Perfection through practice, hard work,<br />

and other massive buildings started booming and meticulous planning and most importantly the desire<br />

most of these buildings imitated the western culture to emerge as a winner in a competitive environment<br />

with glass façade irrespective of the climatic condition was the driving force. The team worked round the<br />

and real need. Thus the team was focused on clock to meet the accelerated schedule and the<br />

creating a difference with a fresh and innovative demanding deadlines. Every minute detail was<br />

approach and the ‘Power of binary’ emerged as the carefully analyzed and incorporated in the initial<br />

concept.<br />

presentation to the client. All possible ways were<br />

explored to convert the innovative concept into an<br />

exciting scheme.<br />

The power of binary<br />

The concept of the design was extracted from the Project Highlights<br />

Binary Language, which forms the backbone of the<br />

Information Technology industry. The ‘0’s and ‘1’s There are four Software Development Blocks<br />

(binary numbers) were ingeniously incorporated into – SDB1 and SDB2 in Phase I and SDB3 and<br />

the design of the façade. The intelligent SDB4 with multi-level car parking in phase II<br />

transformation of a geometric form is weaved into the<br />

entire structure and the standardization of the A state-of-the-art data centre catering to the<br />

structural elements enabled the economical<br />

entire campus is located in the second floor<br />

production of a world class IT campus with extensive<br />

of SDB1<br />

spatial qualities.<br />

For instance, the elimination of 100% glazing through<br />

an alternative design resulted in cost saving which in<br />

turn is used to improve the quality of architecture.<br />

The DNA of success<br />

Service amenities include 3750 persons<br />

dining capacity canteen at three floors (1250<br />

each) with 3 kitchen operators at ground<br />

level. Centralised gymnasium, 500-seater<br />

auditorium, 100 and 150 seater conference<br />

rooms, meditation rooms, library, internet<br />

Success is a combination of several factors, mostly th<br />

kiosk amenities are housed at the 4 floor of<br />

Play of lights by the binary wall<br />

canteen. Convention stores, ATM and<br />

Health Centre are located at the ground<br />

floor.<br />

Open air theatre of 3400 sq.m. area for a<br />

seating capacity of 650 persons which is<br />

surrounded by connecting corridor of tensile<br />

membrane structure between software<br />

blocks/canteen.<br />

The Pergola is designed in such a way that it<br />

acts as a shading device and throws light in a<br />

specific pattern on the software development<br />

block. The play of light by itself forms<br />

different sorts of pattern at different points of<br />

time.

The office master<br />

The presentations to the client set the tone for the<br />

winning formula. It was not just an usual<br />

presentation show-casing the concepts of the<br />

design. Whereas, it covered all the aspects right<br />

from the strategies in master planning to the<br />

intricate details of the interiors. The sustainability<br />

concepts were considered from the very initial<br />

stages. Some of this include: use of recycled water<br />

to increase water efficiency, reducing heat island<br />

effect, and maximum thermal comfort by the use<br />

of energy efficient equipment. This detailed<br />

documentation, later on, emerged as an office<br />

master.<br />

Scope of work<br />

The Cognizant Technology IT Park at Madras<br />

Exports Processing Zone (MEPZ) Chennai has been<br />

termed a milestone project for L&T-ECC. Set to<br />

define style and grandeur, this IT campus is ECC’s<br />

first Lump Sum and Turnkey Project (LSTK) for an<br />

IT major.<br />

EDRC was the Architect, HVAC Consultants,<br />

Structural Consultants, Plumbing Consultants,<br />

Electrical Consultants and LEED Facilitator for the<br />

building. ECC-the construction division of L&T was<br />

the Contractor.<br />

The imposing entrance and majestic view of the Binary Pergola<br />

The major quantum of works included 197000 cu.m.<br />

of excavation, 98000 cu.m. of concrete, 12000 t of<br />

reinforcement, 700 t of structural steel and tendons,<br />

The design and build contract comprised design,<br />

14000 sq.m. of structural glazing and ACP, 80000<br />

architecture and execution of phase I and II works.<br />

sq.m. of tile/granite, 230000 sq.m. of painting<br />

ECC’s scope of work is an end-to-end responsibility<br />

works. The campus having plot area of 14 acres has<br />

involving construction of Software Development<br />

been designed for a built-up area of 20.65 lakh sq.ft<br />

Blocks – SDBs 1, 2, 3, Canteen and SDB 4 with<br />

(Phase I – 10.63 lakh sq.ft & Phase II – 10.02 lakh<br />

multilevel car parking. The scope includes civil,<br />

sq.ft.) and will house 15,300 software professionals.<br />

structural works, architectural and finishing works,<br />

external finishes and claddings works, interior works, With the issuing of LOI on September 29, 2006,<br />

electrical works, plumbing and sanitary works, HVAC works commenced in January 2007 and phase I was<br />

and fire protection works, Building Management made operational from March 2008. The total phase<br />

System, lifts, signage’s, external paving, roads, storm<br />

I buildings including external works were completed<br />

water drainage, landscaping works and all the<br />

by <strong>Dec</strong>ember 2008.<br />

related statutory approvals.<br />

5<br />

ECC Concord <strong>Oct</strong>-<strong>Dec</strong> 09

Challenge<br />

Salient features<br />

Through sustainable design and construction of<br />

facilities, the campus conforms to Green Building<br />

LEED certification norms. It has been registered<br />

with IGBC and all necessary documentation is<br />

being carried out to obtain Silver rating by the<br />

completion of the Phase II works. Features such as<br />

solar passive architecture, preserving natural<br />

features, use of topography, adhering to the local<br />

by-laws, NBC and fire norms have been<br />

incorporated.<br />

ECC Concord <strong>Oct</strong>-<strong>Dec</strong> 09 6<br />

Design & Build External Project<br />

The Solution Innovative Concept<br />

Project Title<br />

Building Use<br />

CTS MEPZ Chennai<br />

IT Facility<br />

Location Chennai<br />

Built-up Area 20.91 lacs sq.ft<br />

Owner Cognizant Technology Solutions<br />

(India) Pvt. Ltd. Chennai<br />

Most of the major equipment and service materials were<br />

imported. The scope of E&I services comprises supply and<br />

installation of major equipment in Phase 1 and Phase 2<br />

valued at Rs. 73 crores. The major electrical materials<br />

comprises 33 kV HT RMU / Consumer Panels (2 nos),<br />

Transformer (2500kVA – 1no, 2000kVA – 4nos &<br />

1750kVA – 4nos), 415V LT panels (414 nos), DG<br />

(2000kVA – 1no, 1500 kVA – 8nos & 625 kVA – 1 no),<br />

Raising mains (956 m), Busducts (489 m), Copper Earth<br />

flats (30 km), Raceways / trays (41 km), Light fixtures<br />

(<strong>32</strong>,651 nos), Wires (2285 km), Street light poles (175<br />

nos), Conduits (198 km) & Cables (157 km). Considering<br />

the space and the requirements of IT operations, the<br />

project called for high-end technology. Dry type<br />

transformers which can be kept inside the building,<br />

sandwich busducts to minimise the space usage, and<br />

solar lighting to utilise the natural resources were<br />

envisaged. For the data centre which is the heart of the IT<br />

park, a special type compact busbar trunking system was<br />

imported from Italy. Being a green building, features such<br />

as solar lighting, maximum usage of natural lighting,<br />

charging point for the vehicle battery in car parking areas<br />

were also incorporated. 100% back up power was<br />

provided. The total requirement of power for Phase 1 is<br />

7.6 MVA and for Phase 2 is 5.4 MVA. Tamil Nadu<br />

Electricity Board supplies 3 MVA of power and the<br />

remaining is sourced from private sector and DG sets.<br />

With the installation of an additional switchyard of (110kV<br />

/ 33kV / 11kV) within MEPZ by TNEB, power distribution<br />

was streamlined.<br />

Mechanical, Electrical and Plumbing (MEP) works in<br />

Phase 1 and 2 comprises Building Management<br />

Systems which automatically controls and monitors<br />

the entire MEP packages such as chillers, air<br />

handling units, chilled water pumps, electrical<br />

system, water management system, lifts, UPS etc.,<br />

Safety and security system comprises analogue<br />

addressable fire alarm, public announcement<br />

system, closed circuit television system to monitor<br />

the day-to-day activities at critical areas in the<br />

building and access control system to control<br />

pedestrian access of the building. Various high-end<br />

services in the datacenter included special safety<br />

Another view of the building

Amphitheatre of 3400 sq. m area for a seating capacity of 650 persons<br />

and security system like VESDA, Inergen gas wasteline. The UPS service component includes UPS<br />

suppression system, Water leak detection system, 4x300 kVA each with 30 minutes backup for<br />

rodent/ repellent system etc.<br />

datacenter, with 15 minutes backup for SDB1<br />

workstation and SDB2 workstation. SDB1 / 2 are<br />

The HVAC services consist of 7 main chillers of 375 TR equipped with 6 passenger lifts (1.5 mps) and one<br />

capacity for Phase 1. Additionally, 70 TR (4 nos), 180 service lift (1 mps), whereas the canteen has 3<br />

TR (4 nos) and 90 TR (2 nos) chillers have been<br />

incorporated for 24x7 system, data centre and SDB2<br />

passenger lifts (1.5 mps) and 2 service lifts (1 mps).<br />

respectively. AHUs of 914 TR, 930 TR capacity and Major machinery deployed included 58 cu.m<br />

756 TR are installed in SDB1, SDB2 and Canteen batching plant, 10 transit mixers, concrete pumps, 3<br />

along with 9000 RM of insulated chilled water tower cranes, Fraco material hoist and Mekaster<br />

piping. The Fire Protection System (FPS) services passenger hoist. The project had a peak asset value<br />

involves hydrant pump, sprinkler pump, stand-by<br />

pump and jockey pump. The Public Health<br />

of 10 crores with monthly hire charges of Rs. 42 lakhs.<br />

Engineering (PHE) services comprise MEPZ water This project won the prestigious “International Safety<br />

supply (approximately 50,000 litres per day), Award” from The British Safety Council for achieving<br />

domestic water supply, flushing water supply, an accident-free record of 10 million safe man hours<br />

domestic water requirement and flushing water which was made possible by effective implementation<br />

treatment, sewage treatment plant of 500 cu.m. per of HSE Management Systems as well as HSE training<br />

day, 11658 RM of GI piping, 9594 RM of soil and imparted to workmen.<br />

7<br />

ECC Concord <strong>Oct</strong>-<strong>Dec</strong> 09

ECC Concord <strong>Oct</strong>-<strong>Dec</strong> 09 8<br />

The inviting interior of the lobby<br />

Winning breeds<br />

confidence<br />

L&T is always known for its highquality<br />

construction. But this iconic<br />

structure with its spell-binding<br />

concept is definitely a landmark<br />

project showcasing the architectural<br />

excellence of Larsen & Toubro in<br />

Commercial Buildings. Impressed<br />

with the design concept, CTS<br />

awarded another contract worth<br />

Rs.280 Crore to design and build<br />

their IT Campus in Kolkata and<br />

projects for Cognizant in Pune<br />

and Siruseri.<br />

This landmark green campus, a result<br />

View of the spacious board room<br />

of Larsen & Toubro’s Imagineering skills came out as an strong sense of place and is noted for its inviting<br />

explicit answer to Cognizant’s passion for making a architecture. More then anything else the client was<br />

difference. The campus is impressive in its look and thoroughly impressed and highly satisfied with the<br />

elemental in its experience with a strong architectural architectural concept and design which marks the height<br />

performance. The campus unquestionably dominates a of L&T’s success and its customer delight.

L&T Brings IT to Vijayawada<br />

ocated at the commercial hub of Andhra L&T had earlier successfully completed HITEC City – a<br />

Pradesh, L&T’s IT Park is the first-of-its-kind world renowned software park at Hyderabad,<br />

Lin Vijayawada and offers an array of Andhra Pradesh and is now developing Vijayawada<br />

sophisticated facilities. This IT/ITES SEZ, IT Park, a prestigious and unique project in coastal<br />

strategically located in the resource rich locality of Andhra, through its special purpose vehicle “L&T<br />

Andhra Pradesh, offers space at most economical HITEC CITY LIMITED”. (A joint venture company of<br />

prices with low operational costs, ideally meeting L&T Infocity Limited and Andhra Pradesh Industrial<br />

individual customer’s requirement. Moreover, it is Infrastructure Corporation Limited)<br />

located only 20 minutes driving distance from the<br />

Vijayawada region has an excellent catchment of<br />

heart of the city and is well connected to the rest of<br />

nearly 1 lakh graduates including 13,500<br />

the country by rail, road and air.<br />

engineers from 35 engineering colleges and 2,600<br />

The Government of Andhra Pradesh<br />

promises several tax exemptions and<br />

concessions to entrepreneurs taking<br />

space in Vijayawada IT Park for<br />

developing Software, IT / ITES<br />

business<br />

Medha - Phase I of Vijayawada's first IT/ITES/SEZ project, promoted by L&T HITEC City Limited<br />

MCA graduates passing out from 46 colleges<br />

annually. Statistics reveal that a sizable percentage<br />

of Indian software professionals are from the state<br />

of Andhra Pradesh and a significant chunk are from<br />

Vijayawada region typifying the excellent<br />

manpower availability for IT/ITES operations.

ECC Concord <strong>Oct</strong>-<strong>Dec</strong> 09 10<br />

Well-appointed front lobby and reception area<br />

Unique walk-to-work concept<br />

density, high ceiling, large and efficient floor plates of<br />

about 42,000 sq. ft, double height entrance lobby<br />

Located on a 30 acre plot at Kesarpalli near and spacious lift lobbies.<br />

Gannavaram airport, which is fast developing as a<br />

The project is complemented with world class<br />

Special Economic Zone (SEZ), L&T Vijayawada<br />

Infrastructure that includes good roads, underground<br />

IT Park is now all set to transform Vijayawada City<br />

HT power distribution, water supply, sewage network,<br />

into a modern IT destination. It is envisaged to<br />

storm water networks, communication network etc.,<br />

develop an integrated township with 11 lakh sq. ft of<br />

Amenities such as food court, fitness centre, business<br />

IT space and 4.5 lakh sq. ft of residential facilities with<br />

centre, banks & ATMs, help desks and amphi-theatre<br />

a unique “walk-to-work” concept. This project will<br />

makes this campus an excellent work place.<br />

generate employment for 15,000 IT professionals<br />

directly and 45,000 personnel indirectly.<br />

The buildings feature “Intelligent Building<br />

Management System” integrating various building<br />

Being developed in the commercial hub, the<br />

systems for energy optimisation and pro-active<br />

park is ideally located to reach all services in the<br />

maintenance. This includes centralized air<br />

city and offers several advantages to companies<br />

conditioning system with bifurcation into human<br />

setting up shop here. This project offers multiand<br />

machine comfort, comprehensive fire<br />

tenented as well as Built-to-Suit (BTS) facility for<br />

protection system including hydrant, automatic<br />

IT companies with plug and work environment<br />

water sprinkler and fire detection & alarm<br />

for ready occupation.<br />

system, highly reliable electrical distribution<br />

Aesthetically designed and constructed by L&T, the system with ample redundancies, 100% diesel<br />

first phase of Vijayawada IT Park (MEDHA) has been power generation back-up, high speed elevators<br />

completed with about 2 lakh sq.ft of IT space. It is a for vertical transportation, seamless data and voice<br />

ground plus four storied structure with low column communication with a choice of service providers.

In order to reduce operational costs some innovative Vijayawada IT Zone Advantages<br />

measures such as district cooling system with water<br />

cooled chillers, treated water for flushing, Cost advantage of Tier II City<br />

synchronization of lifts etc., have been implemented.<br />

Low HR costs – with a rich talent pool<br />

This project that promises amenities at world-class Low operational costs – the building<br />

standards is dynamic enough to cater to all<br />

offers the maximum operational cost<br />

segments of the IT Industry including small &<br />

advantage. Building is equipped with<br />

medium enterprises, with office areas starting from<br />

Distinct cooling system with water cooled<br />

as small as 3500 sq. ft.<br />

chillers, Double glazing, Efficient<br />

Mr. V.Udaya Bhaskar building administration system, etc.<br />

Chief Operating Officer L&T HITEC CITY LIMITED This is also proposed for LEED<br />

certification.<br />

Better logistics<br />

State-of-the-art building and Infra-<br />

structure.<br />

Medha - the first of the five proposed towers was inaugurated by Shri. K. Rosaiah,<br />

Hon’ble Chief Minister of Andhra Pradesh on 28 January 2010.<br />

Perspective view showing all the software blocks

L&T Leads with Green<br />

Technology block<br />

The technology block of L&T at Hazira near Surat has<br />

been awarded the LEED Platinum Rating! This<br />

These Surat-based architects seem to have grasped<br />

the real significance of sustainable design principles<br />

in the modern context.<br />

initiative, by one of the largest construction and<br />

infrastructure industries in the country, of insisting on<br />

Green building design<br />

a `green' building as well as `green' interior can pave A successful built environment is considered so, not<br />

the way for more companies to raise their eco- merely because of the way it was designed. Its success<br />

conscious level, and go green too!<br />

is dependant equally on how well it has been planned<br />

and built, and how well it is being used and<br />

There are several parameters laid down by the maintained. Efficiency and economy in building is<br />

USGBC (U.S. Green Building Council) for granting first generated through the design by a variety of<br />

LEED Platinum, Gold or Silver Ratings to architectural means - optimizing the use of land by the volume of<br />

and interior design projects. Architect Ashok Desai, construction proposed, sharing of structural and<br />

the architect of the building, and architects Vijay and servicing elements, planning dwellings and clusters to<br />

Vaishali Chauhan, the interior designers of the reduce the ratio of movement to habitable area, and<br />

building have religiously followed the rule-book, and so on - depending on the ingenuity of the design<br />

have earned themselves the LEED Platinum Ratings! team. Economy at all costs, however, is never the<br />

Technology Block of L&T - LEED certified (Platinum) Green Building - at Hazira, Gujarat

object of design. It is for the designers to reconcile the appropriate project location can reduce the need for<br />

desire to save costs with the requirements of efficiency private automobile use and reduce urban sprawl.<br />

and well being.<br />

It is also important to minimize project impacts on<br />

The term "green building" is synonymous with `high- surrounding areas after construction is complete<br />

performance building', `sustainable design and and the building is occupied. Addressing heat<br />

construction' as well as other terms that refer to a island effects and reducing light pollution on the site<br />

holistic approach to design and construction. are also vital. Only then, the site can become<br />

integrated into its surroundings and serve as a<br />

Green building design includes all players in an<br />

integrated development process, from the design<br />

team (building owners, architects, engineers and<br />

consultants), the construction team (material<br />

manufacturers, contractors and waste haulers),<br />

maintenance staff, and building occupants. The<br />

green building process results in a high-quality<br />

considerate and beneficial neighbor for the life time<br />

of the building and minimize the impact on micro-<br />

climate, on human life and wildlife. These initiatives<br />

help conserve existing natural areas and restore<br />

damaged areas to provide habitat and promote<br />

biodiversity.<br />

product that maximizes the owner's return on An ideal Green Building aims at limiting disruption<br />

investment. of natural water flows by eliminating storm-water<br />

runoff, increasing on-site infiltration and<br />

Why design green?<br />

eliminating contaminants. It may also be possible to<br />

reuse storm-water for non-potable water purposes<br />

It is common knowledge that the building sector has a such as flushing urinals and toilets, custodial<br />

tremendous impact on the environment. It consumes<br />

more than 30% of our total energy. Buildings are a<br />

applications, and building equipment uses.<br />

major source of the pollutants that cause urban air It is helpful to perform a water balance to determine<br />

quality problems and contribute to climate change. the estimated volumes of water available for reuse.<br />

Storm-water run-off volumes can also be reduced by<br />

Green building practices can substantially reduce designing the building with underground parking, a<br />

such negative environmental impacts associated with<br />

buildings and reverse the trend of unsustainable<br />

strategy that reduces heat island effects significantly.<br />

construction activities. But, that is only part of the Energy consumption can be dramatically reduced<br />

story. Green design also reduces operating costs, through practices that are economical and readily<br />

enhances building marketability, potentially achievable. Improving the energy efficiency of<br />

increases occupant productivity, and helps create a buildings lowers operation costs and reduces<br />

sustainable community.<br />

pollution. Reduction of energy loads through<br />

improved glazing, insulation, day lighting and use of<br />

As of today, there are but a handful of green buildings passive solar features may allow the design team to<br />

in India. With 56 points, this building now stands as<br />

third greenest in India under LEED NC (New<br />

downsize mechanical HVAC systems.<br />

<strong>Construction</strong>) Category and the first LEED Platinum Designing and specifying the use of on-site non<br />

rated project in Gujarat!<br />

polluting renewable technologies can contribute to<br />

the total energy requirement of the project.<br />

Salient features of the 'green'<br />

building:<br />

The architects of this building have studied the norms<br />

for achieving a high level of sustainability in the<br />

architecture of the building. Selection of an<br />

Considering and employing high temperature solar,<br />

geothermal, wind, biomass (other than unsustainably<br />

harvested wood) and bio-gas technologies, are other<br />

green measures.<br />

Photo-voltaics (PVs) are composite materials that<br />

convert sunlight directly into electrical power. In the<br />

13<br />

ECC Concord <strong>Oct</strong>-<strong>Dec</strong> 09

past, these materials were assembled into PV panels Develop and implement a waste management<br />

plan, quantifying material diversion goals.<br />

which required a structure to orient them to the sun. In<br />

recent years, the efficiency of the cells has increased<br />

and the cost has dropped. Building Integrated Photo<br />

<strong>Vol</strong>taics (BIPVs) are increasingly incorporated into<br />

Recycle and /or salvage at least 50% of<br />

construction, demolition and land clearing waste.<br />

(Calculations can be done by weight or volume, but must be<br />

building elements such as the roof, cladding or consistent throughout)<br />

window systems.<br />

ECC Concord <strong>Oct</strong>-<strong>Dec</strong> 09 14<br />

Building material choices are important in<br />

sustainable design because of the extensive<br />

Green interior design<br />

Re-use of old furniture<br />

Interior view of the Green building<br />

network of extraction. Activities to create building As the main feature of the Technology Block, the old<br />

materials pollute the air and water, destroy furniture has been reused along with the furniture in<br />

natural habitats and deplete natural resources. the library in a most efficient and effective way without<br />

Some of the most effective strategies for compromising on the style or aesthetics of the design.<br />

minimizing the environmental impacts of material<br />

use is..<br />

Cubicle height restricted to 3' 6"<br />

90 % of the regularly occupied spaces of building<br />

Reuse existing buildings. have been provided with daylight and views with the<br />

Divert construction, demolition and land clearing<br />

debris from landfill disposal.<br />

help of full-height double glazing and by restricting<br />

the cubicle height to 3' 6".<br />

Redirect recyclable recovered resources back to<br />

Full height glazing<br />

the manufacturing process.<br />

At the second floor, the layout is planned in such a<br />

manner that natural light coming from both the sides is<br />

Redirect reusable materials to appropriate sites. not interrupted.

Double glazing<br />

Landscaping between two glasses creates Green-<br />

House effect. It traps the heat coming into the interior<br />

space thus helping to reduce air-conditioning loads<br />

and acquire natural daylight in the working areas.<br />

Conservation of electricity<br />

Using efficient lighting system that includes<br />

Project Highlights<br />

Project : Technology Block for L&T<br />

Location : L&T Hazira Manufacturing<br />

Complex, Hazira, Surat.<br />

Area : 30,000 sq ft, (G + 2 building)<br />

occupancy sensors, dimmable ballast and Ground floor : Quality assurance department<br />

daylight sensors to dim the lighting based on with facility of chemical<br />

natural light available can conserve electricity.<br />

10KW solar power modules have been installed<br />

to cater 2.5% of the total power load of the<br />

building.<br />

testing laboratory, mechanical<br />

laboratory, calibration room,<br />

display for welding sample, etc.<br />

First floor : Video conference (capacity of<br />

VAV block or terminal unit 40 people), 4 meeting rooms,<br />

training room, server room,<br />

HVAC system having Variable Air <strong>Vol</strong>ume (VAV) boxes surveyor's cabins<br />

has been used. A VAV terminal unit, often called a<br />

VAV box, is the zone-level flow control device. It is Second floor : Staff workstations and cubicles<br />

basically a quality, calibrated air damper with an<br />

automatic actuator. The VAV terminal unit is<br />

Interior : Crest architects<br />

connected to either a local or a central control system.<br />

Water efficiency<br />

Interior<br />

Designers : Ar.Vijay Chauhan, Ar.Vaishali<br />

Water-less urinals, dual flushing cistern and low flow<br />

Chauhan and Poojan Saraiya<br />

rate plumbing fixtures have been used for achieving Architect : Ar.Ashok Desai, Surat<br />

reduction of water use by 30%.<br />

Materials and resources<br />

Recycled content: Use of 20% recycled<br />

content materials.<br />

Local/regional materials: Procuring more<br />

than 20% of material value within 500 miles<br />

from Hazira.<br />

Rapidly renewable materials: Using rapidly<br />

renewable material (raw material having less<br />

than 10 years life cycle) of more than 5% of<br />

total material value i.e. particle boards and<br />

false ceiling.<br />

HVAC : ( P DA ) Pa n k a j D h a r k a r -<br />

Electrical<br />

Consultant Associates, Ahmedabad<br />

consultants : J.P Electrical consultants, Vadodara.<br />

Furniture<br />

Contractor : Om Vishwakarma Furniture<br />

Pvt. Ltd, Mumbai<br />

Civil Contractor: ECC-the <strong>Construction</strong> Division<br />

of L&T<br />

(Source: INSITE magazine)<br />

15<br />

ECC Concord <strong>Oct</strong>-<strong>Dec</strong> 09

Vadodara-Bharuch Superway<br />

he 83.3-km highway between Vadodara Developed by the National Highway Authority of<br />

and Bharuch on NH-8, a part of the Golden India (NHAI), under the Ministry of Road<br />

TQuadrilateral is an important link in the Transport & Highways (MoRTH), the project is<br />

high-density corridor connecting Mumbai and a part of the ambitious National Highway<br />

Delhi. This modern highway passes through the D e v e l o p m e n t P r o g r a m m e ( N H D P ) o f<br />

districts of Anand, Vadodara, and Bharuch and Government of India.<br />

connects various urban centres with a number of<br />

road and rail crossings.<br />

<strong>Construction</strong> of the road was awarded to L&T<br />

Vadodara-Bharuch Tollway Limited, a special<br />

The Vadodara-Bharuch toll way project is the purpose vehicle promoted by L&T Infrastructure<br />

country's most modern highway and is named “VB Development Projects Limited, with a negative grant<br />

SUPERWAY” by the concessionaires. Integrated of about Rs. 474 crore. The total construction cost of<br />

Highway Traffic Management System (HTMS), VMS the project touched around Rs. 750 crore and the<br />

gantries displaying Safety norms and CCTV construction of the project was to be completed<br />

cameras recording the traffic movements at in18 months including 3 months of monsoon. The<br />

important locations, are only some of the post- concession period including construction time is 15<br />

modern features of this hi-tech highway! years. Though the agreement was signed on July<br />

Six lane hi-tech highway (83.3km) connecting Vadodara and Bharuch

11, 2006 and the construction was to commence widening of the existing 83.3 km of 4 lane<br />

from January 2007, the actual work began only carriageway to 6 lanes, the scope of work includes<br />

from <strong>Dec</strong>ember 2007 due to the initial delay in rehabilitation of the existing carriageway, repair &<br />

cutting of trees by forest department, land rehabilitation of 10 major bridges, 36 minor<br />

clearance, etc,. Nevertheless, L&T completed the bridges and 70 culverts. <strong>Construction</strong> of 11 new<br />

project much ahead of schedule in its own stride, by flyovers, 20 new pedestrian underpasses, 2 railway<br />

March <strong>2009</strong> and toll collection started in June over bridges, 8 cattle crossings, 1 vehicular<br />

<strong>2009</strong>. underpass and improvements to 44 minor<br />

intersections. In addition, the scope also includes<br />

NHAI & L&T Vadodara-Bharuch Toll way Limited construction of 8 m wide service roads to a stretch of<br />

jointly appointed Zaidun-Leeng-Artifact Projects 22 km (11km on each side) along with 11 bus bays,<br />

Private Limited as independent consultants for design 31 bus shelters, 2 truck bays, 2 rest areas, one toll<br />

and supervision of the project. plaza (a first-of-its-kind architectural masterpiece in<br />

For logistics and systematic execution of the<br />

project the 83.3 km stretch was divided into four<br />

sections of 20 km each. <strong>Construction</strong> of this<br />

India) and one base camp.<br />

Other important features include installation of<br />

informatory signboards on the road to alert<br />

highway commences at 108/700 and ends at c o m m u t e r s a b o u t t h e h u r d l e s a h e a d<br />

192/000 on NH 8 in the state of Gujarat including weather conditions through global<br />

intersecting a number of state highways having positioning systems (as electronic flash<br />

immense potential to attract increasing traffic as it messages). Emergency call booths and wireless<br />

serves various industrial estates. Apart from<br />

Administrative office and toll plaza<br />

17<br />

ECC Concord <strong>Oct</strong>-<strong>Dec</strong> 09

communication networks enroute are linked to project was to manage the heavy traffic and execute<br />

various service and medical centres for easy the construction activities with utmost safety<br />

access and immediate action. Commuters are also regulations. Through elaborate traffic management<br />

provided with two rest areas including facilities which plan, different teams carried out construction at<br />

houses trauma care units, restaurants, petrol pump remarkable speed without major disturbance to traffic<br />

and garage. Two truck lay bays with wash room and even during the monsoon period.<br />

drinking water facilities provide the much needed<br />

comfort for the truck drivers.<br />

Repetitive overlays on the erstwhile road over the<br />

years had resulted in asphalt crust of thickness<br />

L&T–VBTL designed, engineered, and financed varying from 400 to 700mm. This had to be milled,<br />

this project. <strong>Construction</strong> work was carried out and the milled material was re-used in Wet Mix<br />

by Infrastructure Operating Company - a part Macadan (WMM) and Granular Sub Base (GSB), thus<br />

of L&T’s <strong>Construction</strong> Division. Operations avoiding the problems of space constraint and waste<br />

and maintenance of this hi-tech highway is done accumulation.<br />

by L&T-VBTL.<br />

The CBR of soil was also improved from 2% to 20% by<br />

During execution of the road work, L&T’s way of soil stabilization with lime method for sub-<br />

Infrastructure Operating Company had to meet grade. To ensure good quality of lime (purity > 92%)<br />

several challenges. The main challenge for the<br />

two lime plants had to be installed at site.<br />

Smooth drive on the hi-tech highway

Aesthetically designed toll plaza incorporating integrated traffic management systems<br />

For smooth operation of the toll road, Highway<br />

Traffic Management system has been installed, with<br />

the following features:<br />

Emergency call boxes at 2 km intervals,<br />

connected to control room to help road users<br />

during emergency.<br />

Variable Messaging System to convey traffic<br />

conditions and weather forecast to the road<br />

users.<br />

CCTV in junctions and Plaza to check traffic<br />

intensity, blockage, etc.<br />

Meteorological System to collect weather data.<br />

Radio Communication for smooth<br />

monitoring and patrolling.<br />

Automatic Traffic Classifier & Counter for<br />

traffic information which also helps in data<br />

collection for traffic studies in future.<br />

Automated Tolling with French Technology<br />

has been installed with minimum human<br />

interface.<br />

For the purpose of consistency and early<br />

completion, pre-casting was used extensively.<br />

Girders, box segments for culverts, cattle-crossing,<br />

pedestrian underpass, crash barrier with friction<br />

slab, crash barrier over vent, approach slab, deck<br />

slab planks, hume pipes, box drains, etc. were pre-<br />

cast to reduce construction time frames, and to<br />

exercise better quality control.<br />

The picturesque wedge shaped toll plaza,<br />

constructed for the project is an architectural<br />

masterpiece, and an innovative structure<br />

conceptualized for the first time in India.<br />

In line with L&T’s sustainability initiatives,<br />

several CSR activities were carried out during the<br />

course of execution of the project. Initiatives<br />

such as medical welfare and education of school<br />

children were part of these CSR activities.<br />

Mr. Ravi Prakash<br />

Project Manager<br />

19<br />

ECC Concord <strong>Oct</strong>-<strong>Dec</strong> 09

Water to Pink City<br />

ajasthan, with its varied topography, has a the past three decades and continues to decline at an<br />

wide range of climatic conditions which vary alarming rate. The increasing concentrations of<br />

Rfrom extremely dry and arid in the western nitrates in the ground water supply have also added<br />

Thar deserts to being highly humid in the eastern and to the woes of the public. Jaipur City has grown<br />

southeastern parts of the state. Summer in this land is rapidly in the last few decades both in terms of<br />

a long period with a searing temperature that can population and area. The total area of the walled city<br />

reach extreme limits of over 42° C. Hot winds was 6.7 sq.km back in 1727 when it was founded. By<br />

sweeping across the state with dust storms are also 1965 the municipal limits had further extended to<br />

not uncommon, especially in the desert tracts. cover an area of 185 sq.km and subsequent<br />

additions have now increased the Municipal<br />

Water, in this arid land comes at a premium; people Corporation coverage to an area of 218.26 sq.km.<br />

largely depend on the ground water resource. Jaipur<br />

City, the capital of Rajasthan with a population of The Bisalpur-Jaipur Water Supply Project (BWSP) has<br />

approximately 2.5 million, depends almost entirely come as a welcome relief for the citizens of this<br />

on ground water resources for its potable water beautiful and colorful city. The project envisages<br />

supply. The current rate of ground water abstraction is delivering water from the existing Bisalpur Dam<br />

not sustainable – it is reported that the water table headworks all the way to Jaipur City so as to reduce<br />

throughout the city area has fallen dramatically over the city’s dependence on its ground water resources.<br />

Dam at Bisalpur - the source for drinking water supply to Jaipur

Section of the 56 km long pipeline during construction<br />

The project also includes complementary provisions<br />

for supplying water to other areas.<br />

In order to help ensure successful completion of the<br />

proposed BWSP, the State of Rajasthan requested<br />

Asian Development Bank (ADB) to take up the first<br />

Phase of the project as a part of the ongoing<br />

Rajasthan Urban Infrastructure Development<br />

Project (RUIDP).<br />

Project Highlights<br />

Client : Rajasthan Urban Infrastructure<br />

Development Project, Govt.<br />

of Rajasthan<br />

Type of contract : Design, Build and Turnkey<br />

contract including operation<br />

and maintenance<br />

Scope of contract : Design, supply, construction,<br />

Project duration : 30 months<br />

operation and maintenance<br />

of water supply, treatment &<br />

transmission system from<br />

Bisalpur dam site intake to<br />

Balawala reservoir on the<br />

periphery of Jaipur city.<br />

Commencement : 01.07.2006<br />

Completion : 30.11.<strong>2009</strong><br />

O&M period : 5 years.<br />

The long term strategy for implementing the BWSP Original value : Rs. 481 crores including<br />

is to progressively develop the Bisalpur water of work O&M.<br />

source and provide treated surface water to Jaipur<br />

city and gradually reduce the city’s dependence<br />

on the existing ground water sources. The project,<br />

proposed to be taken up in two phases, has been<br />

designed to supply a total of 540 mld of treated<br />

water to Jaipur city, and 60 mld of treated water<br />

for the rural areas under which the Phase-I is<br />

under execution for a supply of 400 mld treated<br />

water.<br />

BWSP is the single largest integrated water supply<br />

project in India, booked by L&T through a single<br />

contract. This is also the largest contract of drinking<br />

water supply ever ordered by the Rajasthan<br />

Government. The above status of the project makes it<br />

prestigious for both L&T and the Rajasthan<br />

Government alike.<br />

Major components of the project<br />

Supply, Fabrication & laying of 106 km MS<br />

transmission main of 2300/2400 mm<br />

diameter with allied civil works.<br />

<strong>Construction</strong> of a 400 mld Water Treatment<br />

Plant consisting of 9 Pulsator Clarifier (each<br />

29 m x 30 m) , 18 filter beds (each 15 m x 5 m),<br />

one pump house (105m x 20 m) , a reservoir<br />

(98m x 56m), 10 process structures and 27<br />

process & non process buildings including<br />

concrete road & surface drain.<br />

21<br />

ECC Concord <strong>Oct</strong>-<strong>Dec</strong> 09

ECC Concord <strong>Oct</strong>-<strong>Dec</strong> 09 22<br />

<strong>Construction</strong> of 33/3.3 kV substation at intake Won the British Safety Council Award’09.<br />

and WTP sites and connecting 33kV power<br />

transmission.<br />

Achieved 12.2 million safe man hour work at site.<br />

Supply and installation of 9 VT pumps at intake Design of portal frames over existing Ajmer<br />

& 10 HSC pumps at Clear Water Pump House. pipeline using flexible analysis method with<br />

spherical knuckle bearing, ring girders without<br />

<strong>Construction</strong> of 103 km service road and allied thrust & anchor block in raw water main.<br />

cross drainage works.<br />

Record achievements<br />

Inauguration of supply of water to Jaipur city by<br />

Hon’ble Chief Minister on 01.03.09, much<br />

ahead of the schedule.<br />

Water treatment plant<br />

Rock anchoring/drilling executed along hillside<br />

for providing pipe supports at 1.2 km<br />

stretch near Bisalpur Dam.<br />

Erection of 1.2 km length pipeline near<br />

Bisalpur dam was completely done on hilly<br />

terrain.<br />

Won the Quality Trophy for the Year 2007-2008.<br />

Achieved 100 km pipe laying work in 12<br />

Won the RoSPA Gold Award’09 for months at a rate of 15 km per month during the<br />

Occupational Health & Safety. peak periods.

<strong>Construction</strong> of intake Grid Sub Station (GSS) One pipe mill was set up for production of<br />

foundations at strip slope of hill. entire 106 km of pipes for this project<br />

at Phagi due to its strategic location. This<br />

Achieved 93,000 cu.m of concrete and mill helped in the continuos supply of<br />

2,76,000 sq.m shuttering in 21 months. pipes to meet the requirement of the<br />

Dismantling of existing GSS at intake and<br />

commissioning of new 33kV GSS on time.<br />

Out of 76600 t of HR coil 73000 t procured<br />

from China and transported from Mundra Port<br />

to site by road within a period of 3 months.<br />

All buried pipe lines are coated with polyolefin<br />

tape to ensure corrosion resistance throughout<br />

the design life with the help of product procured<br />

from M/s Covalance – USA<br />

All pipe lines have been protected against<br />

corrosion through permanent cathodic<br />

protection system to ensure its designed life<br />

span.<br />

In situ mortar lining was carried out for 106 km<br />

in various dia pipes-2448 mm, 2348 mm, 800<br />

mm & 700 mm to protect corrosion with<br />

minimum C Value of 130<br />

<strong>Construction</strong> of 52 m high surge shaft and four<br />

over head surge tanks<br />

One simple supported MS Bridge of span 25 m<br />

was designed and constructed at IOCL crossing<br />

Raw water transmission main was designed<br />

and constructed over 548 Ring Girders for<br />

carrying the pipe line of 2448 mm dia upto<br />

5.4 km and more than 100 km buried pipe line<br />

to meet requirement of stage two 1020 mld<br />

<strong>Construction</strong> of water treatment plant of<br />

400 mld capacity with 9 pulsators clarifier<br />

and 18 twin bed filters, which is the heart of<br />

the system.<br />

execution team.<br />

Clear Water Reservoir & Pump House<br />

Parameters<br />

Clear Water Reservoir : 1<br />

Size : 98m X 56 m X 4.8 m<br />

Capacity of Reservoir : 25 ML<br />

Material of<br />

<strong>Construction</strong> : RCC<br />

Free Board : 500mm<br />

Pump House : 1<br />

Size : 105 m X 20 m X 15 m<br />

<strong>No</strong> of Pumps : 8 nos Horizontal Split<br />

Casing Pumps for<br />

Jaipur<br />

Capacity : 2800 cu.m/hr ,<br />

Head 42 m<br />

2 nos Horizontal Split<br />

casing Pumps for<br />

Malpura<br />

Capacity : 2600 cu.m/ hr,<br />

Head 42m<br />

Crane : 1 , 10 Mt Double Girder<br />

EOT Crane<br />

Concrete : 9040 cu.m<br />

Formwork : 27700 sq.m<br />

Reinforcement : 770 t<br />

23<br />

ECC Concord <strong>Oct</strong>-<strong>Dec</strong> 09

Challenges<br />

ECC Concord <strong>Oct</strong>-<strong>Dec</strong> 09 24<br />

Major Quantities<br />

Description Quantity<br />

MS Coil for Fabrication of Pipes : 76600 t<br />

Polyolefin Tape Coating : 103000 RM<br />

Inside Cement Mortar<br />

Lining 12MM : 768283 sq.m<br />

VT Pumps & Motors at Intake : 9 set<br />

HSC Pumps & Motors at Cwph : 10 set<br />

Butterfly Valves of Diff. Dia : 43 nos.<br />

Sluice / Scour Valves : 102 nos.<br />

Air Valves : 214 nos.<br />

Expansion Bellows : 50 nos.<br />

Expansion Joints : 28 nos.<br />

Dismantling Joints : 28 nos.<br />

Excavation Work : 2156000 cu.m<br />

Concrete Works : 93000 cu.m<br />

Formwork : 276000 sq.m<br />

Reinforcement Steel : 6400 t<br />

Road Formation Incl. Earthwork : 103000 RM<br />

Granular Sub-base : 139050 cu.m<br />

Wet Mix Macadam : 92700 cu.m<br />

Bituminous Carpet with Seal<br />

Coat : 386250 sq.m<br />

created certain limitations to the team. Other<br />

challenges included the laying of 2448 mm<br />

diameter pipeline over the existing Ajmer<br />

pipeline, apart from continuous traffic, narrow<br />

road over a rocky hill on one side and a steep<br />

valley on the other. The existing pipeline and<br />

dam on the site restricted plans for blasting in<br />

this stretch. The lithosphere of initial stretch of<br />

1.2 km was rocky and was not suitable for<br />

normal excavation. <strong>Construction</strong> of 200 portals<br />

for supporting the pipe was carried out by rock<br />

anchoring technique along the side of traffic<br />

pathway and the existing line. The erection of<br />

surge shaft of height 52m and its supporting<br />

structure at chainage 86.0 m was a challenging<br />

task because public traffic was routed through<br />

the same path and there was the inherent risk of<br />

placing the crane at a sloppy terrain.<br />

Pipeline crossing<br />

The crossing of an existing IOCL pipeline made<br />

the underground pipe-laying less feasible<br />

economically and also from the convenience point<br />

of view. The provision of above-the-ground<br />

pipeline made this job easier. This called for huge<br />

thrust block at both ends and intermediate RCC<br />

portals that carry 25.4 m span MS structural<br />

bridge to lay the pipeline.<br />

Rocky terrain<br />

The high temperature of about 45 degree<br />

centigrade made operations a bit difficult.<br />

Combined with this was the hilly and rocky terrain<br />

of the initial 1.2 km out of 8.4 km through which<br />

the 2448 mm diameter pipeline had to be laid.<br />

This distance also consisted of varied contour<br />

lines, limited space for operation and constant<br />

The BWSP project faced an initial challenge with traffic movement. Straight laying of pipes was not<br />

laying of pipeline at a stretch of 1.2 km in the raw possible due to the presence of 15 French curves,<br />

water main due to space limitation. The presence a RCC thrust block were erected at all turning<br />

of hill on one side and the dam on the other points to hold the thrust.

Raw water receiving cum distribution<br />

chamber<br />

The receiving chamber is a reinforced cement<br />

concrete structure. The raw water flows through<br />

the mains of 2400mm pipes at the inlet tank of<br />

the treatment plant. The top of the chamber is<br />

accessible by the general walkway along the<br />

Clarifier distribution chamber<br />

Provision has also been made (with the help of<br />

Penstocks and RCC Channel) to bypass the clarifiers<br />

for direct feed to filters.<br />

The water from the clarifier is filtered in a battery of 18<br />

gravity-operated filters.<br />

measuring channel. The receiving chamber has The filter plant includes two rows of filters each with a<br />

been connected to the drainage system by 151.4 m² useful surface area. These are covered by a<br />

means of a wall duct with gate valve. A mild steel central gallery for housing the individual filter<br />

ladder has been provided in the chamber to consoles.<br />

access the bottom.<br />

Water from measuring channel enters the clarifier<br />

distribution chamber. The inlet and outlet of the<br />

Parameters<br />

Aquazur V filter : 18 numbers<br />

(15.14 m x 5 m twin bed)<br />

Size : 112 m x 50m x16 m<br />

distribution chambers are designed to provide Plan area : 5600 sq.m<br />

overflow in clarifier distribution box.<br />

Concrete : 7690 cu.m<br />

The Distribution Chamber has been provided with<br />

two compartments, Inlet Compartment and Overflow<br />

Compartment to reduce short-circuiting and to<br />

enable dispersion of chemicals. Each Compartment<br />

is isolated with the help of Penstocks.<br />

Raw water distribution & clarified water collection are<br />

perpendicular with respect to the sludge blanket. This<br />

clarifier is a flat bottom sludge blanket of pulsator type.<br />

Raw water feed takes place through perforated pipes at<br />

the bottom with PVC stilling plates. Air blowers are used<br />

to pulsate the water within the range of 0.6 m to 1 m<br />

using sequential short flushes & prolonged periods of<br />

rest (20 – 40 sec) alternately, hence ensuring sludge<br />

blanket expansion. Automatic sludge draw-off takes<br />

place at the sludge Blanket level. Clear water collection<br />

is through perforated V troughs at the top. Pulsators<br />

have maximum flexibility in case of variable raw water<br />

flow rate and quality of water. It has no submersible<br />

moving mechanical equipment. There is substantial<br />

saving of chemicals is achived due to strong<br />

flocculation in the sludge blanket. Sludge blanket acts<br />

as an absorbent filter which is highly efficient as far as<br />

the removal of colloids and plankton / algae are<br />

concerned .<br />

Filtration<br />

Form work : 36000 sq.m<br />

Reinforcement : 650 t<br />

Parameter Dimension Capacity<br />

Receiving Chamber 28 x25 x 4 700 sq m<br />

Main Distribution Chamber 8.5 x 7.5 x 6 63.75 sq m<br />

Parshall flume with channel 66 x 6.2 x4 409.2<br />

Design Flow 1060 mld<br />

Stage I 624 mld<br />

Stage II 436 mld<br />

Features<br />

An open channel parshall flume with ultra sonic level sensor<br />

Electrically operated penstock at the end of the chamber for the<br />

pulsator distribution chamber.<br />

Alum injection through feeder pipe ensures thorough mixing in the<br />

inlet chamber.<br />

Pre-chlorination through submerged PVC perforated pipes which<br />

are easily detachable for maintenance without disturbing the flow.<br />

PLC controlled on-line water analyzer for the measurement of<br />

ph and turbidity of the raw water.<br />

25<br />

ECC Concord <strong>Oct</strong>-<strong>Dec</strong> 09

ECC Concord <strong>Oct</strong>-<strong>Dec</strong> 09 26<br />

Pulsator Clarifier<br />

Parameters Quantity<br />

Pulsator clarifier : 9 nos<br />

Design flow : 400 mld<br />

Settling velocity<br />

over sludge blanket : < 3 m/hr<br />

Settling velocity<br />

over total area : 2.55 m/hr<br />

Size : 29 m x30m x 5.45m each<br />

Plan Area : 7830 sq.m<br />

Total length of walls : 117 m wall of 5.45 height<br />

Concrete : 10560 cu.m<br />

Form work : 46370 sq.m<br />

Reinforcement : 828 t<br />

Main characteristics<br />

A single layer of homogeneous sand, having<br />

depth according to the filtration rate - a large<br />

water depth above the sand level<br />

A simultaneous air scour and backwash with<br />

water without expansion of the filter bed.<br />

Water enters each filter through a Penstock<br />

Gate with a negligible head-loss and is fed<br />

above the wash-water evacuation trough which<br />

it is submerged during the filtration<br />

Parameter<br />

Filter Annexure Building : 1 no<br />

Size : 19 m X 20m X 14 m<br />

two storied building<br />

Concrete : 700 cu.m<br />

Equipments<br />

Root Blowers : 3 nos<br />

Filling Pumps : 3 nos<br />

Electrically Operated<br />

Train (EOT) : 2 t<br />

Over Head Tank (OHT) : 2000 cu.m<br />

The air scour blowers, wash water filling<br />

pumps, chlorination pumps and the compressed<br />

air production units are located in the filter annex<br />

building.<br />

Recycling<br />

At the end of each backwash, the waste wash<br />

water will gravitate to the recycle tank (usable<br />

capacity 720 cu.m) located close to the filter<br />

battery. After settling, the supernatant is pumped<br />

by submersible pumps to the inlet and the settled<br />

sludge is pumped via flocculator to the<br />

thickeners.<br />

Chlorine mixing<br />

The filtered water channel is extended from filter<br />

battery to chlorine mixing sump, provided<br />

with baffles. Chlorine for final disinfection is<br />

The filtered water, evacuated through a large added into this sump at the end of the filtered water<br />

number of nozzles is collected in a central, channel.<br />

concrete channel located below the washwater<br />

evacuation trough Sludge treatment is sized taking into account the<br />

Each filter outlet is fitted with air actuated raw water flow. However, the backwash water /<br />

regulated butterfly valve<br />

sludge from the clarifiers flow to different<br />

The filter also includes two V-shaped,<br />

submerged troughs (hence its designation as<br />

AQUAZUR V filter) built along the side walls<br />

storage sumps and then pumped to flocculator<br />

cum distribution chamber of thickeners. The<br />

sludge flows to clarifier sludge sump by<br />

which enables surface sweeping during the gravity and mixes with the reserved water. The<br />

washing sequence Sludge from storage sump is lifted to the

Sludge treatment<br />

Clarifier sludge sump : 2<br />

Method of receiving sludge : Gravity<br />

Inlet suspended solid content : 50 mg/ litre<br />

Sludge inlet to thickeners : 22962 kg/day<br />

2<br />

Solid loading rate : 50 kg/m /day<br />

Sludge thickeners : 2 nos<br />

Size :18 m dia x 3.5 m<br />

Sludge drying bed : 61 nos<br />

Size : 30 m x 10 m<br />

Concrete : 3300 cu.m<br />

Formwork : 8300 sq.m<br />

Reinforcement : <strong>32</strong>0 t<br />

Submersible centrifugal pumps : 4 nos<br />

Poly electrolyte pump : 2 no<br />

Positive displacement pump : 2 no<br />

Pulsator Clarifier at the treatment plant<br />

flocculator cum distribution chamber by<br />

submersible centrifugal pumps. After thickening,<br />

the sludge is disposed over the sludge<br />

drying bed.<br />

The sludge treatment infrastructure includes:<br />

Two Clarifier Sludge Sumps, which receive all the<br />

sludge from clarifiers by gravity.<br />

- One recycle tank for backwash wastewater.<br />

- One flocculator cum distribution chamber for the<br />

thickeners<br />

- Two thickeners that enable the sludge<br />

thickening process<br />

- Sludge drying beds.<br />

Ajoy Bhattacharya<br />

Project Manager<br />

K. Vijayakumar<br />

Manager (Commissioning)<br />

27<br />

ECC Concord <strong>Oct</strong>-<strong>Dec</strong> 09

Coal Handling Plant for 2x210 MW<br />

Bakreswar Thermal Power Plant<br />

nd<br />

est Bengal Power Development The 2 stage of the power plant project includes<br />

Corporation Ltd (WBPDCL), a state- construction of a new Coal Handling Plant (CHP)<br />

Wowned premier power utility body -<br />

has undertaken three thermal power plant<br />

projects simultaneously at Bakreswar and two<br />

other places. The present capacity of Bakreswar<br />

Thermal Power plant (BKTPP) has been augmented<br />

designed to cater to the requirement of coal for not<br />

only the two new units of 210 MW each but also for<br />

the 500 MW unit – which is planned for future.<br />

nd<br />

by two additional units of 210 MW each in the 2<br />

The contract for execution of the new coal handling<br />

stage. The Bakreswar Thermal Power plant project<br />

facility for Unit 4 & 5 of BKTPP was awarded to L&T for<br />

is the only project of WBPDCL which has been<br />

Rs. 1346.40 million in <strong>Dec</strong>ember 2004 on a turnkey<br />

financed with assistance from Japan Bank for<br />

basis after undergoing a stiff International<br />

International Cooperation (JBIC) and from the<br />

Competitive Bidding (ICB) procedure and evaluated<br />

point of view of efficiency and performance, the<br />

by the Client’s International and Indian consultants.<br />

Bakreswar Thermal Power plant is the<br />

“Benchmark” power station of WBPDCL and<br />

recognized as one of “The Star Performer” among<br />

all the power stations in India.<br />

Project synopsis<br />

<strong>No</strong>tification for pre-qualification of Bidders was<br />

published in early 2004 and L&T was among the<br />

three short listed bidders qualified to quote for the<br />

Overall view of the power plant showing the complex coal handling plant

DS SYSTEM<br />

MOUNTED ON<br />

P/F CARRIAGE<br />

(TYP)<br />

INMOTION WEIGH BRIDGE<br />

CONTROL ROOMSAC<br />

IWB<br />

RG.-8<br />

RPG.-8<br />

VF-1 VF-2<br />

RG.-9<br />

RPG.-9<br />

CONV.111A<br />

CONV.111B<br />

TRACK HOPPER-2<br />

PF-5<br />

PF-6<br />

CONV.-101A<br />

PF-7<br />

PF-8<br />

CONV.-101B<br />

V<br />

DSSWPWSA SP101<br />

SP102<br />

SP103<br />

SP104<br />

Flow Diagram<br />

TP-101<br />

FG-128<br />

URH-101<br />

URH-102<br />

(RECLAIM HOPPER) (RECLAIM HOPPER)<br />

DSSWPWSA V<br />

TRACK HOPPER SHED<br />

UTP-108<br />

PW SW DS<br />

V<br />

SA<br />

RG.-8<br />

RPG.-8<br />

V<br />

DSSWPWSA VF-1 VF-2<br />

SP107 SP109<br />

SP111<br />

SP108<br />

SP110<br />

SP112<br />

RG.-9<br />

RPG.-9<br />

V<br />

DSSWPWSA<br />

MCC ROOM CONT. ROOM<br />

V<br />

SAC<br />

CABLE TRANSFORMER BATTERY<br />

VAULT ROOM ROOM<br />

CONV.-102A<br />

BW-1<br />

CONV.-102B<br />

BW-2<br />

SP105<br />

SP106<br />

PUMP HOUSE-1/<br />

COMPRESSOR ROOM<br />

S/R<br />

DS<br />

UTP-109<br />

FG-123<br />

SP115<br />

SP116<br />

FG-124<br />

CONV. 114<br />

SP111A<br />

SP112A<br />

PH-101<br />

CRUSHED COAL STOCK PILE<br />

CONV.-113<br />

CONV. 112A<br />

CONV. 112B<br />

UTP-6 (EXIST.)<br />

CONV.-8A (EXISTING)<br />

CONV.-8B (EXISTING)<br />

FG-121 FG-122<br />

TP-102<br />

FG-101<br />

SP117 SP121<br />

SP118<br />

DS<br />

SP122<br />

FG-126<br />

FG-125<br />

FG-127<br />

V<br />

DSSWPWSA TRACK HOPPER<br />

SUB-STATION # 6<br />

B<br />

V<br />

EXISTING<br />

DS<br />

CHUTE<br />

(BY L&T)<br />

SP119<br />

SP120<br />

TP-107<br />

(NOT IN L&T SCOPE)<br />

ILMS-103 CSU<br />

DESWPWSA ILMS-104<br />

C<br />

MD-1<br />

MD-2<br />

DSSWPWSA C<br />

BW-3<br />

BW-4<br />

FG-102<br />

CONV.-103A<br />

CONV.-103B<br />

S/R YARD CONV.110<br />

CRUSHED COAL STOCK PILE<br />

PH-102<br />

GALLERY<br />

(BY L&T)<br />

CONV.109A<br />

CONV.109B<br />

S/R<br />

MCC ROOM CONT. ROOM<br />

COMPRESSOR ROOM<br />

V<br />

SAC<br />

PUMP HOUSE-3<br />

CABLE TRAFO. BATTERY<br />

VAULT ROOM ROOM<br />

CHP SUB-STATION # 5<br />

BUNKER FLOOR<br />

MCC ROOM<br />

CABLE VAULT<br />

B<br />

B<br />

B<br />

CONV.108B<br />

CONV.108A<br />

MT-102<br />

RAW COAL BUNKERS<br />

UUNIT-5<br />

RAW COAL BUNKERS<br />

UUNIT-4<br />

rd<br />

Coal Handling Plant Package – the 3 most critical & the Track Hopper. The coal rake consists special<br />

major package in a thermal power plant.<br />

bottom discharge wagons. Coal of (-) 300mm<br />

size can be unloaded automatically while in<br />

An independent coal handling plant consisting of one slow motion or in stationary condition onto the<br />

track hopper of 4000 t holding capacity, 1600 TPH RCC Track Hopper using compressed air<br />

double conveyor stream along with paddle feeders,<br />

crusher house, trippers etc and 1 no. 1600 TPH<br />

locking/ unlocking system.<br />

stacker reclaimer with associated 1600 TPH Four paddle feeders, each 800 TPH rated<br />

conveyors were proposed to meet the coal capacity are installed at the bottom of Track<br />

requirement of Stage II expansion. The new CHP has Hopper for scooping the coal from track<br />

an interconnection provision with the existing CHP. hopper and to feed coal on to the underground<br />

The first stream of the new CHP was commissioned<br />

conveyors<br />

nd<br />

in <strong>Dec</strong>ember 2007 and the 2 stream was also Uncrushed coal are taken to Crusher house<br />

made ready in March 2008 for coal conveying upto<br />

Boiler bunkers. The Performance Guarantee test for<br />

the plant was successfully completed in March <strong>2009</strong><br />

after the generating units were commissioned by<br />

other agencies.<br />

wherein the coal passes through a set of<br />

dedicated roller screens and ring granulator<br />

type crushers (each 1000 tph). Both the<br />

screened coal below 20mm size and crusher<br />

coal (-) 20mm size are discharged onto<br />

Coal is transported through railway wagons reversible belt feeder. Reversible belt<br />

from mines to site and unloaded at CHP. Empty feeders in turn will feed stacker reclaimer<br />

wagons are taken back to coal mines for further (through yard conveyor) or other conveyors<br />

reloading through the escape route provision in leading to bunker units.<br />

TP-106<br />

FG-119<br />

FG-120<br />

V DSSWPWSA VMS<br />

CR-7<br />

CONV.-7A (EXISTING)<br />

FG-117 FG-118<br />

DESWPWSA RG-7<br />

RPG-7<br />

RS-7<br />

SP113<br />

SP114<br />

UCRUSHER HOUSE-2<br />

ILMS-102<br />

RG-6<br />

RPG-6<br />

RS-6<br />

DESWPWSA CONV.-107A<br />

MT-101<br />

BUNKER SEALING<br />

ARRANGEMENT<br />

CR-5<br />

CR-6<br />

RBF-102<br />

RBF-101<br />

CONV.-107B<br />

RS-5<br />

ILMS-101<br />

RG-5 RG-4<br />

RPG-5 RPG-4<br />

RS-4<br />

FG-104 FG-103<br />

B<br />

B<br />

TP-105<br />

CR-4<br />

FG-113 FG-114<br />

FG-115<br />

FG-116<br />

DSSWPWSA MCC ROOM CONT. ROOM<br />

V<br />

SAC<br />

CABLE TRAFO. BATTERY<br />

VAULT ROOM ROOM<br />

C<br />

MAIN SUB-STATION # 4A/<br />

EL<br />

CHP CONTROL ROOM<br />

PUMP HOUSE-2/<br />

COMPRESSOR ROOM<br />

CONV.-106B<br />

CONV.-106A<br />

MT-102<br />

CONV. 104A<br />

CONV. 104B<br />

CONV. 10A (EXISTING)<br />

CONV. 10B (EXISTING)<br />

B<br />

FG-107<br />

TP-103<br />

DSSWPWSA DESWPWSA FG-105<br />

FG-108<br />

FG-106<br />

MT-101<br />

BUNKER SEALING<br />

ARRANGEMENT<br />

CONV. 105A<br />

CONV. 105B<br />

TP-5<br />

(EXISTING)<br />

B<br />

CONV.-6A(EXIST.)<br />

CONV.-6B(EXIST.)<br />

TP-104<br />

FG-111 FG-109<br />

FG-112<br />

FG-110<br />

DSSWPWSA 29<br />

BLIND FLANGE<br />

CONV. FOR FUTURE<br />

ECC Concord <strong>Oct</strong>-<strong>Dec</strong> 09

In the crushed coal stockpile, coal will be<br />

carried by trunk conveyor and stacked by<br />

Stacker cum Reclaimer. In the reclaiming<br />

mode, Stacker cum Reclaimer will reclaim coal<br />

from stockpile and will discharge on to trunk<br />

conveyor. Also in case of emergency when<br />

Stacker cum Reclaimer is out of operation and<br />

coal is needed in the bunker from stockpile,<br />

dozers will be used to supplement coal to either<br />

of the 2 Reclaim Hoppers, wherefrom coal can<br />

be fed to the bunkers.<br />

Both the direct path as well as two reclaim paths<br />

will convey the coal to bunker conveyors. Each<br />

of the bunker conveyor is provided with<br />

Travelling Trippers through which the bunkers<br />

of Unit 4 & 5 will be fed.<br />

Track hopper<br />

The track hopper complex is 210m long with a<br />

holding capacity of 4000 t with maintenance bays at<br />

both ends along with erection hatch, staircase, etc.<br />

The live railway lines on one side and ash-water pipe<br />

rake on the other side of the track hopper location<br />

made it very critical for the excavation and<br />

construction activities. In order to tackle the constraint<br />

and to meet the deadline, innovative arrangements<br />

were made to cast 5m high wall at one lift to reduce<br />

the casting time.<br />