Oct - Dec 2009 • Vol. No. 32 Issue No. 2 • - L&T Construction

Oct - Dec 2009 • Vol. No. 32 Issue No. 2 • - L&T Construction

Oct - Dec 2009 • Vol. No. 32 Issue No. 2 • - L&T Construction

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ECC Concord <strong>Oct</strong>-<strong>Dec</strong> 09 48<br />

Instrumentation<br />

Control and Automation plays a crucial role in the<br />

safe operation of Jamnagar Refinery which is virtually<br />

unmanned. This is achieved by the massive<br />

instrumentation works that involve the latest<br />

technology available.<br />

E & I played a crucial role in executing the critical<br />

instrumentation job in the priority areas of one unit of<br />

CRUDE-311, and one unit of DHDS-01 and in the<br />

non-priority areas which later on turned into a priority<br />

area like FCCU, CRUDE-312, ALKALISATION, CFP<br />

(DHDS-02, LCO).<br />

The scope of instrumentation work involved<br />

installation of 4798 junction boxes, 260<br />

instrument panels, 633 t structural steel inclusive<br />

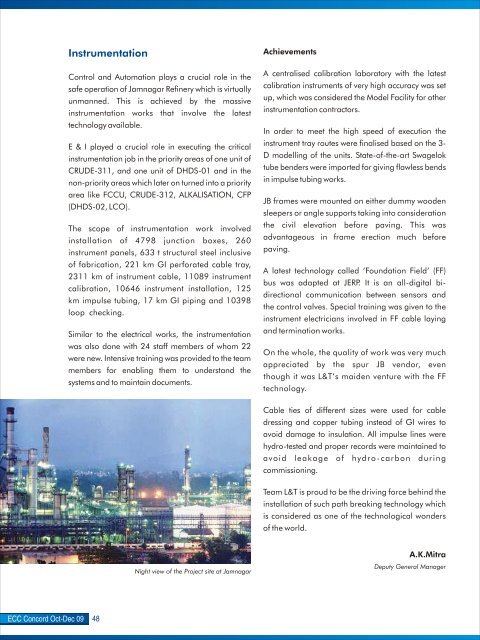

Night view of the Project site at Jamnagar<br />

Achievements<br />

A centralised calibration laboratory with the latest<br />

calibration instruments of very high accuracy was set<br />

up, which was considered the Model Facility for other<br />

instrumentation contractors.<br />

In order to meet the high speed of execution the<br />

instrument tray routes were finalised based on the 3-<br />

D modelling of the units. State-of-the-art Swagelok<br />

tube benders were imported for giving flawless bends<br />

in impulse tubing works.<br />

JB frames were mounted on either dummy wooden<br />

sleepers or angle supports taking into consideration<br />

the civil elevation before paving. This was<br />

advantageous in frame erection much before<br />

paving.<br />

of fabrication, 221 km GI perforated cable tray, A latest technology called ‘Foundation Field’ (FF)<br />

2311 km of instrument cable, 11089 instrument<br />

bus was adapted at JERP. It is an all-digital bicalibration,<br />

10646 instrument installation, 125<br />

directional communication between sensors and<br />

km impulse tubing, 17 km GI piping and 10398<br />

the control valves. Special training was given to the<br />

loop checking.<br />

instrument electricians involved in FF cable laying<br />

Similar to the electrical works, the instrumentation<br />

and termination works.<br />

was also done with 24 staff members of whom 22 On the whole, the quality of work was very much<br />

were new. Intensive training was provided to the team<br />

appreciated by the spur JB vendor, even<br />

members for enabling them to understand the<br />

though it was L&T’s maiden venture with the FF<br />

systems and to maintain documents.<br />

technology.<br />

Cable ties of different sizes were used for cable<br />

dressing and copper tubing instead of GI wires to<br />

avoid damage to insulation. All impulse lines were<br />

hydro-tested and proper records were maintained to<br />

avoid leakage of hydro - carbon during<br />

commissioning.<br />

Team L&T is proud to be the driving force behind the<br />

installation of such path breaking technology which<br />

is considered as one of the technological wonders<br />

of the world.<br />

A.K.Mitra<br />

Deputy General Manager