Oct - Dec 2009 • Vol. No. 32 Issue No. 2 • - L&T Construction

Oct - Dec 2009 • Vol. No. 32 Issue No. 2 • - L&T Construction

Oct - Dec 2009 • Vol. No. 32 Issue No. 2 • - L&T Construction

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

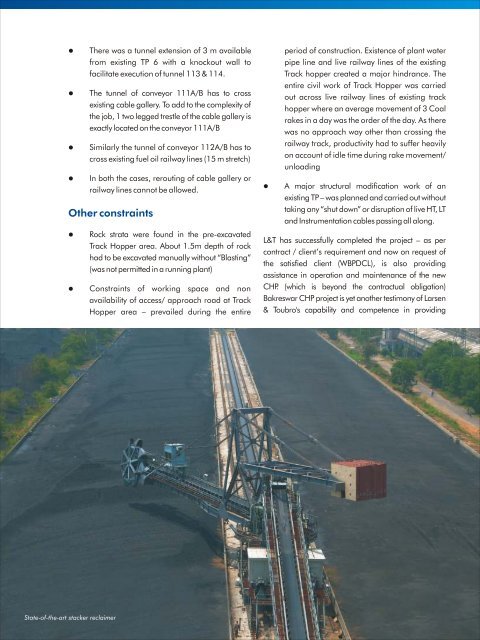

There was a tunnel extension of 3 m available period of construction. Existence of plant water<br />

from existing TP 6 with a knockout wall to pipe line and live railway lines of the existing<br />

facilitate execution of tunnel 113 & 114. Track hopper created a major hindrance. The<br />

entire civil work of Track Hopper was carried<br />

The tunnel of conveyor 111A/B has to cross<br />

existing cable gallery. To add to the complexity of<br />

the job, 1 two legged trestle of the cable gallery is<br />

exactly located on the conveyor 111A/B<br />

out across live railway lines of existing track<br />

hopper where an average movement of 3 Coal<br />

rakes in a day was the order of the day. As there<br />

was no approach way other than crossing the<br />

Similarly the tunnel of conveyor 112A/B has to<br />

railway track, productivity had to suffer heavily<br />

cross existing fuel oil railway lines (15 m stretch)<br />

on account of idle time during rake movement/<br />

unloading<br />

In both the cases, rerouting of cable gallery or<br />

railway lines cannot be allowed.<br />

A major structural modification work of an<br />

existing TP – was planned and carried out without<br />

Other constraints<br />

taking any “shut down” or disruption of live HT, LT<br />

and Instrumentation cables passing all along.<br />

Rock strata were found in the pre-excavated<br />

Track Hopper area. About 1.5m depth of rock<br />

had to be excavated manually without “Blasting”<br />

(was not permitted in a running plant)<br />

Constraints of working space and non<br />

availability of access/ approach road at Track<br />

Hopper area – prevailed during the entire<br />

State-of-the-art stacker reclaimer<br />

L&T has successfully completed the project – as per<br />

contract / client’s requirement and now on request of<br />

the satisfied client (WBPDCL), is also providing<br />

assistance in operation and maintenance of the new<br />

CHP. (which is beyond the contractual obligation)<br />

Bakreswar CHP project is yet another testimony of Larsen<br />

& Toubro's capability and competence in providing