Oct - Dec 2009 • Vol. No. 32 Issue No. 2 • - L&T Construction

Oct - Dec 2009 • Vol. No. 32 Issue No. 2 • - L&T Construction

Oct - Dec 2009 • Vol. No. 32 Issue No. 2 • - L&T Construction

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Sludge treatment<br />

Clarifier sludge sump : 2<br />

Method of receiving sludge : Gravity<br />

Inlet suspended solid content : 50 mg/ litre<br />

Sludge inlet to thickeners : 22962 kg/day<br />

2<br />

Solid loading rate : 50 kg/m /day<br />

Sludge thickeners : 2 nos<br />

Size :18 m dia x 3.5 m<br />

Sludge drying bed : 61 nos<br />

Size : 30 m x 10 m<br />

Concrete : 3300 cu.m<br />

Formwork : 8300 sq.m<br />

Reinforcement : <strong>32</strong>0 t<br />

Submersible centrifugal pumps : 4 nos<br />

Poly electrolyte pump : 2 no<br />

Positive displacement pump : 2 no<br />

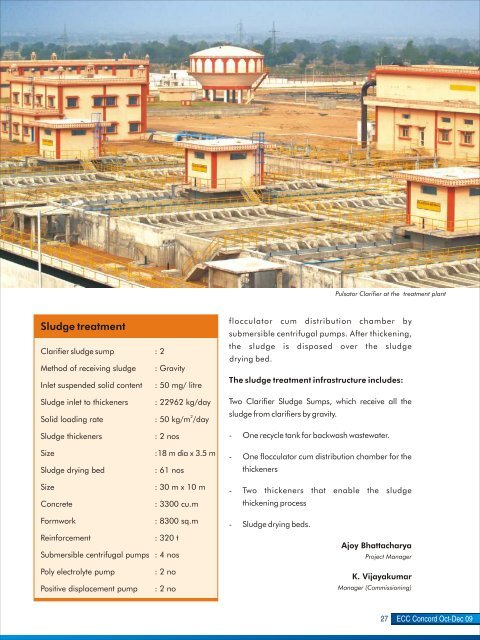

Pulsator Clarifier at the treatment plant<br />

flocculator cum distribution chamber by<br />

submersible centrifugal pumps. After thickening,<br />

the sludge is disposed over the sludge<br />

drying bed.<br />

The sludge treatment infrastructure includes:<br />

Two Clarifier Sludge Sumps, which receive all the<br />

sludge from clarifiers by gravity.<br />

- One recycle tank for backwash wastewater.<br />

- One flocculator cum distribution chamber for the<br />

thickeners<br />

- Two thickeners that enable the sludge<br />

thickening process<br />

- Sludge drying beds.<br />

Ajoy Bhattacharya<br />

Project Manager<br />

K. Vijayakumar<br />

Manager (Commissioning)<br />

27<br />

ECC Concord <strong>Oct</strong>-<strong>Dec</strong> 09