3D DISCRETE DISLOCATION DYNAMICS APPLIED TO ... - NUMODIS

3D DISCRETE DISLOCATION DYNAMICS APPLIED TO ... - NUMODIS

3D DISCRETE DISLOCATION DYNAMICS APPLIED TO ... - NUMODIS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2 Introduction<br />

Time (sec)<br />

10 3<br />

1<br />

10 -3<br />

10 -6<br />

10 -9<br />

10 -12<br />

Molecular<br />

Dynamics<br />

10 -11 10 -10 10 -9<br />

10 -8<br />

10 -7<br />

10 -6<br />

Single crystal<br />

models<br />

Dislocation<br />

Dynamics<br />

10 -5<br />

Space (m)<br />

Homogenization technique<br />

Polycrystal<br />

models<br />

Continuum mechanics<br />

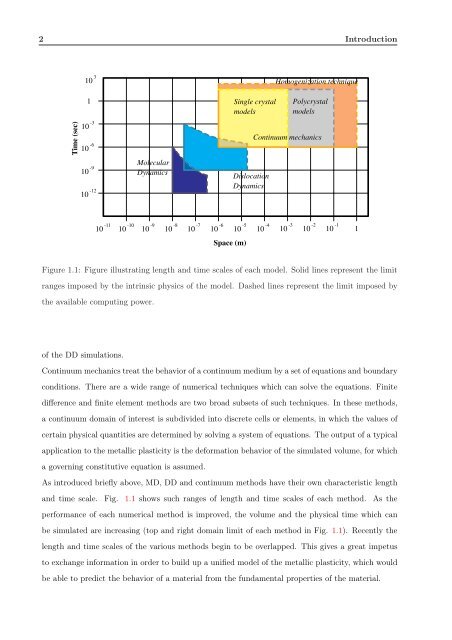

Figure 1.1: Figure illustrating length and time scales of each model. Solid lines represent the limit<br />

ranges imposed by the intrinsic physics of the model. Dashed lines represent the limit imposed by<br />

the available computing power.<br />

of the DD simulations.<br />

Continuum mechanics treat the behavior of a continuum medium by a set of equations and boundary<br />

conditions. There are a wide range of numerical techniques which can solve the equations. Finite<br />

difference and finite element methods are two broad subsets of such techniques. In these methods,<br />

a continuum domain of interest is subdivided into discrete cells or elements, in which the values of<br />

certain physical quantities are determined by solving a system of equations. The output of a typical<br />

application to the metallic plasticity is the deformation behavior of the simulated volume, for which<br />

a governing constitutive equation is assumed.<br />

As introduced briefly above, MD, DD and continuum methods have their own characteristic length<br />

and time scale. Fig. 1.1 shows such ranges of length and time scales of each method. As the<br />

performance of each numerical method is improved, the volume and the physical time which can<br />

be simulated are increasing (top and right domain limit of each method in Fig. 1.1). Recently the<br />

length and time scales of the various methods begin to be overlapped. This gives a great impetus<br />

to exchange information in order to build up a unified model of the metallic plasticity, which would<br />

be able to predict the behavior of a material from the fundamental properties of the material.<br />

10 -4<br />

10 -3<br />

10 -2<br />

10 -1<br />

1