Drawings - Peak Engineering and Construction Ltd

Drawings - Peak Engineering and Construction Ltd

Drawings - Peak Engineering and Construction Ltd

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SHEET NUMBER<br />

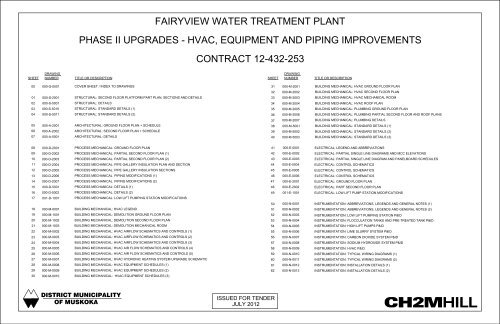

00 000-G-0001 COVER SHEET / INDEX TO DRAWINGS<br />

31<br />

01<br />

02<br />

03<br />

04<br />

05<br />

06<br />

07<br />

08<br />

09<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

17<br />

18<br />

19<br />

20<br />

21<br />

22<br />

23<br />

24<br />

25<br />

26<br />

27<br />

28<br />

29<br />

30<br />

DRAWING<br />

000-S-2001<br />

000-S-5010<br />

000-A-2001<br />

000-A-2002<br />

000-A-5001<br />

000-D-2001<br />

000-D-2002<br />

000-D-2004<br />

001-D-1001<br />

000-M-0001<br />

000-M-1001<br />

000-M-1002<br />

000-M-1003<br />

000-M-0002<br />

000-M-0003<br />

000-M-0004<br />

000-M-0005<br />

000-M-0006<br />

000-M-0007<br />

000-M-0008<br />

TITLE OR DESCRIPTION SHEET NUMBER<br />

000-S-5001 STRUCTURAL: DETAILS<br />

000-S-5011<br />

000-D-5001<br />

PROCESS MECHANICAL: GROUND FLOOR PLAN<br />

000-D-2003 PROCESS MECHANICAL: PARTIAL SECOND FLOOR PLAN (2)<br />

000-D-2005<br />

000-D-2006<br />

000-D-2007<br />

000-D-5002<br />

000-M-0009<br />

ARCHITECTURAL: DETAILS<br />

PROCESS MECHANICAL: PARTIAL SECOND FLOOR PLAN (1)<br />

BUILDING MECHANICAL: HVAC LEGEND<br />

BUILDING MECHANICAL: DEMOLITION GROUND FLOOR PLAN<br />

BUILDING MECHANICAL: DEMOLITION SECOND FLOOR PLAN<br />

BUILDING MECHANICAL: HVAC AIRFLOW SCHEMATICS AND CONTROLS (1)<br />

BUILDING MECHANICAL: HVAC AIRFLOW SCHEMATICS AND CONTROLS (2)<br />

BUILDING MECHANICAL: HVAC AIRFLOW SCHEMATICS AND CONTROLS (3)<br />

BUILDING MECHANICAL: HVAC AIR FLOW SCHEMATICS AND CONTROLS (4)<br />

BUILDING MECHANICAL: HVAC AIR FLOW SCHEMATICS AND CONTROLS (5)<br />

BUILDING MECHANICAL: HVAC HYDRONIC HEATING SYSTEM UPGRADE SCHEMATIC<br />

BUILDING MECHANICAL: HVAC EQUIPMENT SCHEDULES (1)<br />

BUILDING MECHANICAL: HVAC EQUIPMENT SCHEDULES (2)<br />

000-M-0010 BUILDING MECHANICAL: HVAC EQUIPMENT SCHEDULES (3)<br />

DISTRICT MUNICIPALITY<br />

OF MUSKOKA<br />

PHASE II UPGRADES - HVAC, EQUIPMENT AND PIPING IMPROVEMENTS<br />

STRUCTURAL: SECOND FLOOR PLATFORM PART PLAN, SECTIONS AND DETAILS<br />

STRUCTURAL: STANDARD DETAILS (1)<br />

STRUCTURAL: STANDARD DETAILS (2)<br />

ARCHITECTURAL: GROUND FLOOR PLAN + SCHEDULE<br />

ARCHITECTURAL: SECOND FLOOR PLAN + SCHEDULE<br />

PROCESS MECHANICAL: PIPE GALLERY INSULATION PLAN AND SECTION<br />

PROCESS MECHANICAL: PIPE GALLERY INSULATION SECTIONS<br />

PROCESS MECHANICAL PIPING MODIFICATIONS (1)<br />

PROCESS MECHANICAL PIPING MODIFICATIONS (2)<br />

PROCESS MECHANICAL: DETAILS (1)<br />

PROCESS MECHANICAL: DETAILS (2)<br />

PROCESS MECHANICAL: LOW LIFT PUMPING STATION MODIFICATIONS<br />

BUILDING MECHANICAL: DEMOLITION MECHANICAL ROOM<br />

FAIRYVIEW WATER TREATMENT PLANT<br />

CONTRACT 12-432-253<br />

JULY 2012<br />

32<br />

33<br />

34<br />

35<br />

36<br />

37<br />

38<br />

39<br />

40<br />

41<br />

42<br />

43<br />

44<br />

45<br />

46<br />

47<br />

48<br />

49<br />

50<br />

51<br />

52<br />

53<br />

54<br />

55<br />

56<br />

57<br />

58<br />

59<br />

60<br />

61<br />

62<br />

ISSUED FOR TENDER<br />

DRAWING<br />

000-M-2001<br />

000-M-2002<br />

000-M-2003<br />

000-M-2004<br />

000-M-2005<br />

000-M-5001<br />

000-M-5002<br />

000-M-5003<br />

000-E-0001<br />

000-E-0002<br />

000-E-0003<br />

000-E-2001<br />

000-E-2002<br />

000-N-0001<br />

000-N-0002<br />

000-N-0003<br />

000-N-0004<br />

000-N-0005<br />

000-N-0006<br />

000-N-0007<br />

TITLE OR DESCRIPTION<br />

BUILDING MECHANICAL: HVAC GROUND FLOOR PLAN<br />

BUILDING MECHANICAL: HVAC SECOND FLOOR PLAN<br />

BUILDING MECHANICAL: HVAC ROOF PLAN<br />

BUILDING MECHANICAL: PLUMBING GROUND FLOOR PLAN<br />

000-M-2006 BUILDING MECHANICAL: PLUMBING PARTIAL SECOND FLOOR AND ROOF PLANS<br />

000-M-2007 BUILDING MECHANICAL: PLUMBING DETAILS<br />

000-E-0004<br />

000-E-0005<br />

BUILDING MECHANICAL: STANDARD DETAILS (1)<br />

BUILDING MECHANICAL: STANDARD DETAILS (2)<br />

BUILDING MECHANICAL: STANDARD DETAILS (3)<br />

ELECTRICAL: LEGEND AND ABBREVIATIONS<br />

ELECTRICAL: PARTIAL SINGLE LINE DIAGRAMS AND MCC ELEVATIONS<br />

ELECTRICAL: PARTIAL SINGLE LINE DIAGRAM AND PANELBOARD SCHEDULES<br />

ELECTRICAL: CONTROL SCHEMATICS<br />

ELECTRICAL: CONTROL SCHEMATICS<br />

000-E-0006 ELECTRICAL: CONTROL SCHEMATICS<br />

ELECTRICAL: GROUND FLOOR PLAN<br />

ELECTRICAL: PART SECOND FLOOR PLAN<br />

001-E-1001 ELECTRICAL: LOW LIFT PUMP STATION MODIFICATIONS<br />

000-N-0008<br />

INSTRUMENTATION: ABBREVIATIONS, LEGENDS AND GENERAL NOTES (1)<br />

INSTRUMENTATION: ABBREVIATIONS, LEGENDS AND GENERAL NOTES (2)<br />

INSTRUMENTATION: LOW LIFT PUMPING STATION P&ID<br />

INSTRUMENTATION: FLOCCULATION TANKS AND PRE-TREATED TANK P&ID<br />

INSTRUMENTATION: HIGH LIFT PUMPS P&ID<br />

INSTRUMENTATION: LIME SLURRY SYSTEM P&ID<br />

000-N-0009 INSTRUMENTATION: HVAC P&ID<br />

000-N-0010<br />

000-N-0011<br />

000-N-0012<br />

000-N-0013<br />

BUILDING MECHANICAL: HVAC MECHANICAL ROOM<br />

INSTRUMENTATION: CARBON DIOXIDE SYSTEM P&ID<br />

INSTRUMENTATION: SODIUM HYDROXIDE SYSTEM P&ID<br />

INSTRUMENTATION: TYPICAL WIRING DIAGRAMS (1)<br />

INSTRUMENTATION: TYPICAL WIRING DIAGRAMS (2)<br />

INSTRUMENTATION: INSTALLATION DETAILS (1)<br />

INSTRUMENTATION: INSTALLATION DETAILS (2)

A<br />

B<br />

C<br />

D<br />

N<br />

1070<br />

1 2 3 4 5 6<br />

FILTER AND<br />

TANK AREA<br />

0553-001<br />

TYP<br />

125<br />

AL L75x75x6<br />

SHELF ANGLE<br />

ALL AROUND,<br />

BEAM CONN, SEE<br />

EXISTING TYP<br />

0514-056<br />

CONC CURB<br />

A SECTION<br />

1:30<br />

B<br />

-<br />

0514-056<br />

TYP<br />

SIDE MOUNTED AL RAILING<br />

BOTH SIDES SEE ARCH<br />

SPECIFICATION AND<br />

, TYP<br />

0552-817<br />

PROVIDE NEW POSTS AT<br />

END OF MODIFIED RAILING<br />

TYP BOTH SIDES<br />

AL W150x18<br />

CONN SEE,<br />

SECOND FLOOR PART PLAN<br />

NTS<br />

REMOVABLE<br />

600 SECTION<br />

AL L75x75x6<br />

ON 3 SIDES OF<br />

REMOVABLE<br />

SECTION<br />

SIDE MOUNTED AL RAILING<br />

BOTH SIDES SEE ARCH<br />

SPECIFICATION AND<br />

, TYP<br />

0552-817<br />

EXISTING AL RAILING<br />

TO BE REMOVED AND<br />

MODIFIED<br />

ALUMINUM TOEBOARD<br />

EXISTING TOC<br />

AL L75x75x6 AL L75x75x6<br />

A<br />

-<br />

AL L75x75x6<br />

AL W150x18<br />

T.O. GRATING<br />

EL 297.85<br />

AL W150x18<br />

AL L75x75x6<br />

1900<br />

EXISTING TOC<br />

EXISTING TOC<br />

AL L75x75x6<br />

AL L75x75x6<br />

150<br />

2300<br />

150<br />

44mm THICK<br />

AL GRATING<br />

0553-001<br />

EXISTING<br />

AL RAILING<br />

E<br />

DESIGN<br />

SUPERIMPOSED<br />

LL=7.5 kPa<br />

ALUM RAILING CONTINUOUSLY<br />

WELDED TO 12mm ALUM PLATE<br />

44mm THICK<br />

AL GRATING<br />

0553-001<br />

T.O. GRATING<br />

EL 297.85<br />

AL W150x18<br />

CONN SEE,<br />

0514-056<br />

TYP<br />

N<br />

CUT AND REMOVE EXISTING<br />

CURB AND RAILING.<br />

GRIND DOWN AT LEAST<br />

25mm BELOW SLAB. FILL THE<br />

HOLES WITH NON SHRINK<br />

NON FERROUS GROUT. MATCH<br />

SURFACE FINISH WITH EXISTING<br />

EXISTING AL RAILING<br />

PORTION TO BE<br />

MODIFIED<br />

150 x 150 x 12mm THICK<br />

ALUMINUM PLATE ANCHORED<br />

TO EXIST WALL WITH<br />

4-16M 304 STAINLESS STEEL BOLTS<br />

COMPLETE WITH HILTI RE 500<br />

ADHESIVE A325<br />

B SECTION<br />

1:30<br />

E<br />

A<br />

-<br />

1200 MAX<br />

42.16 DIAMETER SCHEDULE 40<br />

ALUMINUM RAILS, TYP<br />

42.16 DIAMETER SCHEDULE 80<br />

ALUMINUM POSTS, TYP<br />

T/O FIN FLOOR<br />

OR PLATFORM<br />

150 x 150 x 12mm THICK<br />

2205 STAINLESS STEEL PLATE<br />

NTS<br />

MIN BEARING<br />

DIMENSION, SEE NOTE 10<br />

16mm DRILL-IN ANCHORS<br />

@ 450mm CENTERS,<br />

200mm EMBEDMENT AND<br />

AT ENDS, TYP<br />

150<br />

150<br />

EQUAL EQUAL<br />

981<br />

200<br />

125<br />

MIN 150<br />

B<br />

-<br />

DETAIL-A<br />

30 30<br />

SECTION-B<br />

SIDE MOUNTED GUARD ON CONCRETE<br />

NTS<br />

125mm x 6mm CONTINUOUS<br />

ALUMINUM TOE-BOARD<br />

GRATING<br />

BEARING BAR<br />

GRATING<br />

THICKNESS<br />

ATTACH GRATING TO<br />

ANGLE WITH CLAMP<br />

AS SPECIFIED<br />

AL L75x75x6<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

6.<br />

7.<br />

0552-817<br />

GENERAL NOTES:<br />

50<br />

5<br />

5<br />

304 SST COUNTERSUNK<br />

SELF DRILLING FASTENERS<br />

DRIVEN INTO ROD MIN 10mm<br />

(4 PER POST)<br />

6mmTHICK SST SETTING RING<br />

CONT WELDED TO SST ROD<br />

31.75mm DIAMETER 2205 STAINLESS<br />

STEEL ROD WELDED TO 12 mm<br />

2205 STAINLESS STEEL PLATE ANCHORED<br />

TO CONCRETE WALL WITH 4-16M<br />

304 STAINLESS STEEL BOLTS<br />

C/W HILTI RE 500 ADHESIVE A325<br />

NOTE:<br />

MINIMUM YIELD STRENGTH OF SST ROD<br />

AND PLATE TO BE 450 KPa. WELD ROD<br />

AND PLATE WITH A FILLER METAL OF<br />

MATCHING OR GREATER YIELD STRENGTH<br />

31.75mm DIAMETER 2205 STAINLESS<br />

STEEL ROD WELDED TO 12 mm<br />

2205 STAINLESS STEEL PLATE ANCHORED<br />

TO CONCRETE WALL WITH 4-16M<br />

304 STAINLESS STEEL BOLTS<br />

C/W HILTI RE 500 ADHESIVE A325<br />

GRATING SHALL BE LIGHT DUTY GRATING UNLESS OTHERWISE<br />

NOTED ON DRAWINGS.<br />

FOR SERRATED BEARING BARS, INCREASE GRATING THICKNESSES<br />

SHOWN IN TABLES BY 6mm.<br />

8. BAND ALL EDGES. MATCH DEPTH OF BEARING BAR.<br />

9.<br />

GRATING SPAN SEE PLAN.<br />

STANDARD ALUMINUM GRATING<br />

INDIVIDUAL GRATING SECTIONS SHALL NOT EXCEED 900mm IN WIDTH<br />

OR WEIGH MORE THAN 34 kg, UNLESS INDICATED OTHERWISE.<br />

SHOP DRAWINGS BASED ON FIELD DIMENSIONS SHALL BE SUBMITTED<br />

TO THE ENGINEER PRIOR TO FABRICATION.<br />

METAL SUPPORTS THAT ARE TO BE EMBEDDED IN CONCRETE SHALL<br />

BE TYPE 316 STAINLESS STEEL.<br />

BEARING BAR THICKNESS FOR GRATING TO BE 5mm MINIMUM.<br />

SEE SPECIFICATIONS FOR SPACING OF BEARING AND CROSS BARS.<br />

THE HORIZONTAL CLEARANCE BETWEEN THE GRATING AND<br />

GRATING SUPPORTS SHALL NOT BE LESS THAN 6mm NOR<br />

GREATER THAN 13mm.<br />

10. FOR MIN BEARING HORIZONTAL DIMENSION = 25mm.<br />

0553-001<br />

FILENAME: 000-S-2001.dgn<br />

PLOT DATE: 2012\07\25 PLOT TIME: 6:16:12 PM<br />

DISTRICT M UNICIPALITY<br />

DATE<br />

PROJ<br />

DWG<br />

OF M USKOKA<br />

SHEET<br />

FAIRYVIEW W ATER TREATMENT PLANT<br />

STRUCTURAL<br />

NTS<br />

MB<br />

07/2012 ISSUED FOR TENDER<br />

AT<br />

0<br />

PHASE I UPGRADES<br />

SECOND FLOOR PLATFORM<br />

PART PLAN, SECTIONS, AND DETAILS<br />

VERIFY SCALE<br />

BAR IS 25mm ON<br />

APVD<br />

BY<br />

REVISION<br />

DATE<br />

NO.<br />

CONTRACT 12-432-253<br />

ORIGINAL DRAWING.<br />

0 25 MM<br />

APVD<br />

CHK<br />

DSGN DR<br />

AT<br />

AT NA<br />

RP<br />

2012/07/27<br />

424251<br />

000-S-2001<br />

01of62 CH2M HILL 2012. ALL RIGHTS RESERVED.<br />

c<br />

THIS DOCUMENT, AND THE IDEAS AND DESIGNS INCORPORATED HEREIN, AS AN INSTRUMENT OF PROFESSIONAL SERVICE, IS THE PROPERTY OF<br />

CH2M HILL AND IS NOT TO BE USED, IN W HOLE OR IN PART, FOR ANY OTHER PROJECT WITHOUT THE W RITTEN AUTHORIZATION OF CH2MHILL.<br />

REUSE OF DOCUMENTS:<br />

ISSUED FOR TENDER

A<br />

B<br />

C<br />

D<br />

0330-105<br />

CONT KEY ALL<br />

15M@200 EW<br />

15M@200<br />

15M@200 DRIIL-IN DWLS<br />

AROUND RERIMETER<br />

CUT AND REMOVE<br />

100(W)x50 DEEP<br />

AROUND CONC<br />

EQPT PAD, TYP<br />

EXISTING OPENING<br />

1 2 3 4 5 6<br />

DIM TO SUIT<br />

SECTION DETAIL<br />

1 1:20<br />

EXISTING OPENING<br />

4 1:10<br />

NEW OPENING<br />

DIM TO SUIT EQPT<br />

ROUGHEN CONC<br />

SURFACE, TYP<br />

TO SUIT<br />

500 MIN<br />

EXISTING ROOF<br />

TOC EL<br />

TYPICAL EQUIPMENT PAD ON ROOF<br />

PLAN/SECTION<br />

DETAIL<br />

PROVIDE 20x20<br />

REGLET ALL<br />

AROUND, TYP<br />

NOTE 1<br />

EXISTING CONC<br />

TOPPING<br />

EXISTING CONC<br />

ROOF SLAB<br />

PROVIDE INJECTION<br />

HOSE WS ALL AROUND<br />

AND MAKE JOINT<br />

WATERTIGHT, TYP<br />

(SMALLER OPENING THAN EXISTING REQUIRED)<br />

NEW OPENING<br />

DIM TO SUIT EQPT<br />

CHEMICAL RESISTANT<br />

COATING ALL AROUND<br />

15M@300 DRILL-IN DWLS<br />

EMBEDMENT=250mm<br />

0330-105<br />

75x75 CONTINUOUS COVE<br />

ALL AROUND USING<br />

PREMIXED FIBRE PATCH<br />

OV/ST OR EQUIVALENT<br />

CHEMICAL RESISTANT<br />

COATING COVERING<br />

COMPLETE FLOOR<br />

WITHIN THE<br />

CONTAINMENT AREA<br />

15M@300<br />

0330-105<br />

150<br />

INSIDE OUTSIDE<br />

SECTION DETAIL<br />

2 1:20<br />

000-D-2001<br />

FILL WALL/SLAB OPENING<br />

WITH CONCRETEFINISHES<br />

TO MATCH ADJACENT<br />

EXISTING CONCRETE<br />

FINISH, TYP<br />

DRILL-IN DWLS,<br />

WALL/SLAB<br />

TYP<br />

SEE NOTES 2, 3, 4<br />

EXISTING CONC<br />

EXISTING FLOOR<br />

TOC EL<br />

SPILL CONTAINMENT CURB<br />

NEW OPENING<br />

DIM TO SUIT EQPT<br />

MAKE CONCRETE FINISH<br />

GOOD AND TO MATCH<br />

EXISTING CONCRETE<br />

FINISH, TYP<br />

300<br />

15M@200<br />

CONTAINMENT WALL<br />

MAKE EXISTING SURFACE<br />

ROUGH FOR CONTINUOUS<br />

COVE<br />

EXISTING<br />

CONC SLAB<br />

PROVIDE INJECTION<br />

HOSE WS ALL AROUND<br />

CUT AND REMOVE<br />

100(W)x50 DEEP<br />

CONT KEY ALL SIDES<br />

NEW OPENING<br />

DIM TO SUIT EQPT<br />

EXISTING OPENING<br />

PLAN/SECTION<br />

DETAIL<br />

5 1:10<br />

CONC CURB<br />

ALL AROUND<br />

DUCT<br />

NOTE 1<br />

EXISTING CONC<br />

TOPPING<br />

PROVIDE INJECTION<br />

HOSE WS ALL AROUND<br />

CUT AND REMOVE<br />

100(W)x50 DEEP<br />

CONT KEY<br />

SECTION DETAIL<br />

3 1:20<br />

000-M-2003<br />

EXISTING CONC<br />

SEE<br />

EXISTING OPENING<br />

SEE NOTES 2, 3, 4<br />

(LARGER OPENING THAN EXISTING REQUIRED)<br />

DIM TO SUIT<br />

200 200<br />

CUT AND REMOVE<br />

WALL AND REBARS,<br />

0330-808<br />

EXISTING CONC<br />

WALL/SLAB<br />

DUCT CURB<br />

TO SUIT<br />

500 MIN<br />

2-15M TOP<br />

15M@250<br />

0330-105<br />

EXISTING ROOF<br />

TOC EL<br />

EXISTING CONC<br />

ROOF SLAB<br />

15M@250 DRILL-IN DWLS<br />

MIN EMBEDMENT=150mm<br />

300<br />

GRANULAR A.<br />

SEE NOTE 1<br />

NATIVE, UNDISTURBED<br />

INORGANIC SOIL<br />

GENERAL NOTES:<br />

1.<br />

2.<br />

3.<br />

4.<br />

6.<br />

7.<br />

8.<br />

9.<br />

NOT IN CONTRACT<br />

SEE 4 , IF THE CONCRETE OPENING REQUIRED IS LARGER THAN<br />

4600<br />

CARBON DIOXIDE TANK PAD<br />

6<br />

ARCHITECTURAL ROOF FINISHES NOT SHOWN FOR CLARITY<br />

FOR SIZE AND LOCATION OF CURB AROUND OPENING,<br />

SEE BUILDING MECHANICAL DRAWINGS.<br />

FOR SIZE AND LOCATION OF MODIFIED OPENINGS<br />

SEE BUILDING MECHANICAL DRAWINGS.<br />

THE CONCRETE OPENING SIZE IN STRUCTURE SHALL BE MODIFIED<br />

TO SUIT NEW EQUIPMENT. IF THE CONCRETE OPENING REQUIRED<br />

IS SMALLER THAN EXISTING, FILL AROUND OPENING,<br />

-<br />

5<br />

EXISTING, SEE .<br />

FILL OPENING IN WALL OR SLAB, SEAL PIPE PENETRATION<br />

WHICH ARE NOT REQUIRED ANY MORE WITH THE SAME<br />

MATERIAL AND TO MATCH FINISH AS EXISTING, SEE<br />

AND .<br />

0330-141 0330-142<br />

DETAIL<br />

NTS<br />

15M@200<br />

T&B, EW<br />

-<br />

THE CMU WALL OPENING SIZE IN STRUCTURE SHALL BE MODIFIED<br />

TO SUIT NEW EQUIPMENT. IF THE OPENING REQUIRED IS LARGER THAN<br />

THE EXISTING, CUT AND REMOVE CMU WALL AND FINISH THE FACES.<br />

IF THE CMU WALL OPENING REQUIRED IS SMALLER THAN EXISTING<br />

FILL AROUND WITH SAME MATERIAL TO MATCH EXISTING.<br />

FOR CMU WALL OPENINGS THAT ARE NOT REQUIRED ANY MORE,<br />

FILL WITH SIMILAR BLOCK AND FINISH TO MATCH EXISTING.<br />

FOR DEMOLITION OF EXISTING CONCRETE EQUIPMENT PADS,<br />

CUT AND REMOVE EXISTING EQUIPMENT PAD, SEE<br />

0330-143<br />

.<br />

MAKE CONCRETE FINISH GOOD AND TO MATCH<br />

ADJACENT CONCRETE FINISH, TYPICAL.<br />

10. FOR DOWELING IN EXISTING CONCRETE WALL/SLAB, SEE 0330-105 TYP.<br />

11. USE 32 mPa CONCRETE, CLASS S-3, WITH MAXIMUM 20 mm AGGREGATE,<br />

TYP FOR ENTIRE PROJECT.<br />

12. USE REINFORCING BARS: CAN/CSA G30.18 MG2 (R 2007) GRADE 350R, TYP<br />

FOR ENTIRE PROJECT.<br />

NOTES:<br />

300<br />

1. COMPACT GRANULAR MATERIAL AS INDICATED TO 100%<br />

OF STANDARD PROCTOR MAXIMUM DRY DENSITY.<br />

2. REFER TO CIVIL DRAWINGS FOR ADDITIONAL DETAILS.<br />

1<br />

1<br />

FILENAME: 000-S-5001.dgn<br />

PLOT DATE: 2012\07\26 PLOT TIME: 10:13:47 AM<br />

DISTRICT M UNICIPALITY<br />

DATE<br />

PROJ<br />

DWG<br />

OF M USKOKA<br />

SHEET<br />

FAIRYVIEW W ATER TREATMENT PLANT<br />

STRUCTURAL<br />

NTS<br />

MB<br />

07/2012 ISSUED FOR TENDER<br />

AT<br />

0<br />

PHASE I UPGRADES<br />

DETAILS<br />

VERIFY SCALE<br />

BAR IS 25mm ON<br />

APVD<br />

BY<br />

REVISION<br />

DATE<br />

NO.<br />

CONTRACT 12-432-253<br />

ORIGINAL DRAWING.<br />

0 25 MM<br />

APVD<br />

CHK<br />

DSGN DR<br />

AT<br />

AT NA<br />

RP<br />

2012/07/27<br />

424251<br />

000-S-5001<br />

02of62 CH2M HILL 2012. ALL RIGHTS RESERVED.<br />

c<br />

THIS DOCUMENT, AND THE IDEAS AND DESIGNS INCORPORATED HEREIN, AS AN INSTRUMENT OF PROFESSIONAL SERVICE, IS THE PROPERTY OF<br />

CH2M HILL AND IS NOT TO BE USED, IN W HOLE OR IN PART, FOR ANY OTHER PROJECT WITHOUT THE W RITTEN AUTHORIZATION OF CH2MHILL.<br />

REUSE OF DOCUMENTS:<br />

ISSUED FOR TENDER

A<br />

B<br />

C<br />

D<br />

ADDL HORIZ &<br />

VERT REINF EA<br />

FACE, SEE NOTE 6,<br />

1 - 15M EF, MIN<br />

EXISTING WALL<br />

REINF, BEND<br />

50mm CLR OF PIPE<br />

GRIND 40mm WIDE<br />

SMOOTH CONT<br />

SURFACE @<br />

CTR OF WALL<br />

FOR WS<br />

INSTALLATION<br />

6mmx25mm<br />

HYDROPHILIC<br />

WATERSTOP<br />

BONDED TO<br />

EXST CONC<br />

(CONT ALL<br />

AROUND OPNG)<br />

SEE NOTE 8<br />

EXST WALL<br />

MIN EDGE DISTANCE<br />

REBAR DOWELS,<br />

SEE DRAWINGS<br />

FOR SIZE<br />

AND SPACING<br />

NEW WALL OR<br />

SLAB EXTENSION<br />

MINIMUM<br />

NOTES:<br />

TYP<br />

FORM 15x20x25mm<br />

DEEP RECESS FOR<br />

DRYPACK GROUT,<br />

END OF EXISTING WALL OR SLAB<br />

STD LAP LENGTH<br />

PER CSA A23.1<br />

50 CLR,<br />

STD LAP LENGTH<br />

PER CSA A23.1<br />

EMBEDMENT "A"<br />

DOWEL<br />

SIZE<br />

10M<br />

15M<br />

20M<br />

25M<br />

30M<br />

1 2 3 4 5 6<br />

ELEVATION<br />

UNLIMITED EDGE DISTANCE<br />

MINIMUM<br />

EDGE DIST<br />

1. FOLLOW ADHESIVE MANUFACTURER’S INSTRUCTIONS FOR INSTALLATION.<br />

2. USE MINIMUM EMBEDMENTS SHOWN, EXCEPT USE MANUFACTURER’S<br />

3. LOCATE DOWELS CENTERED IN WALL OR SLAB UNLESS OTHERWISE NOTED ON<br />

ADHESIVE DOWEL<br />

NTS<br />

LIMITED EDGE DISTANCE<br />

100mm<br />

125mm<br />

175mm<br />

190mm<br />

MINIMUM<br />

EMBEDMENT A<br />

0330-105<br />

MINIMUM<br />

EMBEDMENT B<br />

65mm 125mm 200mm<br />

200mm<br />

265mm<br />

355mm<br />

380mm<br />

MINIMUM RECOMMENDED EMBEDMENT IF GREATER.<br />

1<br />

T/2<br />

2<br />

T<br />

SECTION<br />

150+/-<br />

MINIMUM EMBEDMENT "B"<br />

HOLE DIA AS RECOMMENDED<br />

BY ADHESIVE MANUFACTURER<br />

T/2, SEE NOTE 4<br />

NEW WALL OR SLAB<br />

330mm<br />

400mm<br />

560mm<br />

600mm<br />

"T"<br />

EXISTING REINFORCING<br />

FACE OF EXISTING WALL OR SLAB<br />

EXISTING REINFORCING<br />

DRAWINGS. WHERE 2 ROWS OF DOWELS INDICATED, STAGGER SPACING & LOCATE<br />

ALTERNATING DOWELS AT MINIMUM EDGE DISTANCE FROM OPPOSITE FACES.<br />

TYP<br />

15M HOOP x PIPE<br />

OD + 100mm EA FACE<br />

SQUARE OPENING<br />

PIPE OD + 300<br />

SLOPE TOP OF OPNG<br />

AS SHOWN TO<br />

PREVENT ENTRAPPED<br />

AIR POCKET<br />

EXTEND PLYWOOD<br />

FORM 75mm MIN ABOVE<br />

OPNG, GRIND TO<br />

REMOVE EXTRA CONC<br />

IN POURING SPOUT<br />

CONC<br />

CLOSURE<br />

SEEP RING<br />

PIPE, SEE<br />

PLANS<br />

WATERSIDE<br />

OF WALL<br />

NOTES:<br />

1. SAW-CUT 25mm DEEP x PIPE OD + 300mm<br />

SQUARE SCORE LINE ON EACH FACE OF<br />

WALL. (VERIFY DEPTH OF CUT TO CLEAR<br />

REINFORCING.) (INCREASE HEIGHT AS<br />

NOTED AT TOP ON WATERSIDE FACE<br />

FOR POURING.)<br />

2. CHIP TO REMOVE THE CONCRETE WITHIN<br />

THE SCORE LINE, WHILE PRESERVING<br />

THE EXISTING WALL REINFORCING.<br />

3. CUT EXISTING REINFORCING AT CENTER<br />

OF OPENING AND BEND TO CLEAR PIPE.<br />

4. GRIND 40mm WIDE x CONT SMOOTH<br />

SURFACE ALL AROUND THE OPENING<br />

AT CENTER OF WALL. CLEAN SURFACES<br />

AND BOND CONTINUOUS HYDROPHILIC<br />

WATERSTOP IN PLACE.<br />

5. INSTALL WALL PIPE. (COAT CONCRETE<br />

ENCASED PORTION OF PIPE WITH SPECIFIED<br />

COATING SYSTEM.)<br />

6. INSTALL ADDITIONAL REINFORCING EACH<br />

FACE, EACH SIDE, ABOVE AND BELOW PIPE.<br />

HORIZONTAL REINFORCING TO HAVE<br />

COMBINED AREA EQUAL TO AREA OF<br />

HORIZONTAL REINFORCING CUT. VERTICAL<br />

REINFORCING TO HAVE COMBINED AREA<br />

EQUAL TO AREA OF VERTICAL<br />

REINFORCING CUT.<br />

7. SOAK CONCRETE SURFACES AND WITHIN<br />

15-MINUTES CAST CONCRETE CLOSURE.<br />

(CONCRETE CLOSURE MUST BE CAST<br />

BEFORE HYDROPHILIC WATERSTOP<br />

EXPANDS.) FORM GROOVE ON ALL SIDES<br />

OF OPENING EXCEPT AT TOP ON THE<br />

POUR SIDE.<br />

8. CLEAN SURFACES OF FORMED GROOVE<br />

WITH POWER WIRE BRUSH OR<br />

SANDBLASTING AND DRY-PACK WITH<br />

NON-SHRINK GROUT AFTER NEW<br />

CONCRETE MIN 28-DAYS OLD.<br />

PIPE PENETRATION - EXISTING WALL<br />

NTS<br />

4. SEE DETAIL 0330-818 FOR HOLE PROCEDURES.<br />

EXISTING<br />

STRUCTURAL<br />

SLAB<br />

0330-022<br />

15M@300 EW<br />

T & B, TYP<br />

NTS<br />

40<br />

20<br />

CLR<br />

CLR<br />

CURE CONCRETE FOR 7 DAYS<br />

FOR PATCHING. DO NOT REMOVE<br />

SUPPORTING FORMS AND DO NOT<br />

LOAD UNTIL CONCRETE ATTAINS<br />

FULL 28 DAY DESIGN STRENGTH<br />

ROUGHEN SURFACE OF EXISTING<br />

SLAB OPENING TO FULL 6mm<br />

MINIMUM AMPLITUDE, CLEAN AND<br />

SOAK PRIOR TO POURING CONCRETE<br />

1200 MAX<br />

NOTES:<br />

SLAB OPENING<br />

100mm MIN ALL AROUND<br />

OR AS REQUIRED BY<br />

ANCHORAGE<br />

CALCULATIONS<br />

PAD HEIGHT AS<br />

REQD, 90mm MIN,<br />

UNO, SEE NOTE 1<br />

EXST OR NEW SUSPENDED<br />

SLAB OR SLAB ON GRADE,<br />

FOR THICKNESS SEE PLANS<br />

1. WHEN ANCHORAGE OF EQUIPMENT TO PAD IS<br />

REQUIRED, USE CONCRETE ANCHORS SPECIFIED.<br />

2. CONCRETE PADS FOR ELECTRICAL EQUIPMENT SHALL BE<br />

90mm HIGH, UNLESS NOTED OTHERWISE.<br />

SLAB THICKNESS TO<br />

MATCH EXISTING (150mm MIN)<br />

16mm DIAMETER x 450mm THREADED ROD<br />

ADHESIVE ANCHORS, CENTER IN SLAB,<br />

AT 200mm SPACING ALL AROUND PERIMETER<br />

OF OPENING, DRILL AND EPOXY 150mm<br />

MINIMUM INTO EXISTING CONCRETE<br />

(3 ANCHORS MINIMUM EACH SIDE OF OPENING)<br />

PLAN/SECTION<br />

0330-141<br />

NTS<br />

EXISTING SLAB/WALL<br />

OPENING REPAIR<br />

CONCRETE<br />

NOTE:<br />

15M@200 EW, 25mm CLR<br />

EQUIPMENT<br />

EQUIPMENT PAD<br />

20mm CHAMFER, TYP<br />

15M ADHESIVE DOWEL<br />

@ 200 OC @ PERIMETER<br />

0330-105 & SEE NOTE 13.<br />

CONSTRUCTION JOINT,<br />

ROUGHEN & CLEAN PRIOR<br />

TO PLACING PAD<br />

CONCRETE EQUIPMENT PAD<br />

CHIP SIDES OF EXISTING<br />

OPENING BACK TO 3:12<br />

SLOPE AS SHOWN ROUGHEN<br />

SURFACE TO FULL 6mm<br />

MINIMUM AMPLITUDE, CLEAN<br />

AND SOAK PRIOR TO POURING<br />

EXISTING STRUCT<br />

CONCRETE SLAB<br />

0330-056<br />

600 MAX<br />

SLAB OPENING<br />

REINF WITH 15M@300 EW, T&B,<br />

40mm CLEAR, FOR ALL OPENING<br />

LARGER THAN 300mm<br />

FOR REPAIR OF LARGER SLAB OPENINGS SEE<br />

NTS<br />

PLAN/SECTION<br />

0330-142<br />

0330-141<br />

EXISTING SLAB/WALL<br />

OPENING REPAIR<br />

WIDTH AND HEIGHT<br />

OF CURB AS NOTED<br />

ON DRAWINGS<br />

CURE CONCRETE FOR 7 DAYS<br />

NOTE 1,<br />

TYP<br />

NOTE:<br />

1. DRILL IN DOWELS SHALL NOT BE USED<br />

CONCRETE CURB ON EXISTING SLAB<br />

NTS<br />

FOR PATCHING. DO NOT REMOVE<br />

SUPPORTING FORMS AND DO NOT<br />

LOAD UNTIL CONCRETE ATTAINS<br />

FULL 28-DAY STRENGTH<br />

FINISH SLAB OR WALL UNDER REMOVED<br />

CONCRETE TO MATCH EXISTING ADJACENT<br />

CONCRETE FINISH, REPAIR ROUGH OR<br />

DAMAGED SURFACES AS NOTED<br />

NOTES:<br />

1. REMOVE CONCRETE OUT TO SOUND CONCRETE.<br />

2. IF CHIPPING INTO THE SURFACE OF THE EXISTING SLAB OR WALL TO REMAIN IS<br />

REQUIRED, MAKE EDGES PERPENDICULAR TO THE SURFACE. DO NOT FEATHER<br />

EDGES.<br />

3. FILL DEFECTIVE AREA WITH NON-SHRINK GROUT OR AN APPROVED PREPACKAGED<br />

PATCHING MATERIAL TO MATCH APPREARANCE OF ADJACENT CONCRETE SURFACES.<br />

4. USE APPROVED BONDING AGENT ON SURFACES TO BE PATCHED PRIOR TO PLACING<br />

NON-SHRINK GROUT.<br />

5. DEMONSTRATE METHODS FOR REPAIR USING ACTUAL MATERIALS, METHODS, AND<br />

CURING PROCEDURES REQUIRED BY MATERIAL MANUFACTURERS. CONSULT WITH<br />

BONDING AGENT MANUFACTURER AND NON-SHRINK GROUT MANUFACTURER ON<br />

TECHNIQUES.<br />

EXISTING STRUCT<br />

CONCRETE SLAB<br />

WHERE CONCRETE BEAM PRESENTS BELOW.<br />

CONCRETE DEMOLITION<br />

NTS<br />

2-15M @ TOP &<br />

15M@300 WHEN CURB<br />

HEIGHT EXCEEDS 300mm,<br />

MIN 2 BARS FOR CURB<br />

HEIGHT LESS THAN 300mm<br />

ROUGHEN<br />

CONCRETE<br />

SURFACE<br />

REINFORCING BAR DOWELS,<br />

DRILL INTO EXISTING CONCRETE,<br />

SEE<br />

0330-818<br />

, 20M@300 TYPICAL<br />

UNO ON PLANS<br />

NON-SHRINK GROUT<br />

0330-080B<br />

SAW-CUT AND CHIP TO REMOVE<br />

EXISTING CONCRETE TO BE<br />

REMOVED, USE CARE NOT TO<br />

DAMAGE EXISTING ADJACENT<br />

CONCRETE SURFACES TO REMAIN<br />

CORE DRILL 50mm DIAMETER HOLE,<br />

40mm DEEP, AND CHIP AND GRIND<br />

TO REMOVE EXISTING REINFORCING<br />

AND EQUIPMENT ANCHORS TO 40mm<br />

MIN BELOW TOP OF EXISTING CONCRET.<br />

CLEAN AND SOAK, AND DRY-PACK WITH<br />

0330-143<br />

EXISTING CONCRETE<br />

TO REMAIN<br />

FILENAME: 000-S-5010.dgn PLOT DATE: 2012\07\25 PLOT TIME: 6:17:00 PM<br />

DISTRICT M UNICIPALITY<br />

DATE<br />

PROJ<br />

DWG<br />

OF M USKOKA<br />

SHEET<br />

FAIRYVIEW W ATER TREATMENT PLANT<br />

STRUCTURAL<br />

NTS<br />

MB<br />

07/2012 ISSUED FOR TENDER<br />

AT<br />

0<br />

PHASE I UPGRADES<br />

STANDARD DETAILS (1)<br />

VERIFY SCALE<br />

BAR IS 25mm ON<br />

APVD<br />

BY<br />

REVISION<br />

DATE<br />

NO.<br />

CONTRACT 12-432-253<br />

ORIGINAL DRAWING.<br />

0 25 MM<br />

APVD<br />

CHK<br />

DSGN DR<br />

AT<br />

AT NA<br />

RP<br />

2012/07/27<br />

424251<br />

000-S-5010<br />

03of62 CH2M HILL 2012. ALL RIGHTS RESERVED.<br />

c<br />

THIS DOCUMENT, AND THE IDEAS AND DESIGNS INCORPORATED HEREIN, AS AN INSTRUMENT OF PROFESSIONAL SERVICE, IS THE PROPERTY OF<br />

CH2M HILL AND IS NOT TO BE USED, IN W HOLE OR IN PART, FOR ANY OTHER PROJECT WITHOUT THE W RITTEN AUTHORIZATION OF CH2MHILL.<br />

REUSE OF DOCUMENTS:<br />

ISSUED FOR TENDER

A<br />

B<br />

C<br />

D<br />

NEW OPENING<br />

SAW-CUT LINE<br />

EXISTING WALL ELEVATION OR SLAB PLAN DETAIL<br />

NOTES:<br />

PRIOR TO SAW CUTTING NEW<br />

OPENING DRILL SUFFICIENT<br />

NUMBER OF 25mm DIA HOLES<br />

IN ALL CORNERS TO PREVENT<br />

OVERCUTTING.<br />

1. LOCATE ANY EXISTING UTILITIES THAT COULD BE<br />

AFFECTED WITH DEMOLITION. REPORT TO THE<br />

ENGINEER IF ANY UTILITIES ARE FOUND.<br />

2. STAY WITHIN LIMITS OF OPENING, DO NOT OVERCUT.<br />

3. BURN BACK EXPOSED REINFORCING 25mm AND<br />

DRY PACK WITH NON SHRINK GROUT.<br />

REFER TO DETAIL 0330-143 FOR PROCEDURE SHOWN.<br />

NEW PIPE OPENING THROUGH<br />

EXISTING WALL OR SLAB<br />

NTS<br />

1 2 3 4 5 6<br />

0330-808<br />

FOR HORIZONTAL BARS<br />

NTS<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

‘Le’<br />

NOTES:<br />

d<br />

REINFORCING DOWEL BAR<br />

AS SHOWN ON DRAWINGS<br />

DRILL HOLE OF DIAMETER AND DEPTH AS REQUIRED.<br />

CLEAN HOLE OF DUST AND DEBRIS.<br />

FILL HOLE WITH DOWELLING GROUT.<br />

FOR VERTICAL BARS<br />

INSTALL REINFORCING DOWEL BAR AND WIPE AWAY OVERFLOW.<br />

SECURE DOWEL BAR FIRMLY IN POSITION AND DO NOT DISTURB<br />

BAR FOR 24 HOURS AFTER INSTALLATION.<br />

6. FOR OTHER DETAILS SEE 0330-105 .<br />

FOR HYDRAULIC CEMENT GROUT<br />

d = BAR DIA + 20mm<br />

Le : 15M - 200mm<br />

20M - 250mm<br />

25M - 300mm<br />

DOWELLING IN EXISTING CONCRETE<br />

d<br />

‘Le’<br />

0330-818<br />

65,<br />

SEE<br />

NOTE 1<br />

1.<br />

2.<br />

3.<br />

BEAM/WALL CONNECTION - ALUMINUM<br />

NTS<br />

150 MIN<br />

NOTES:<br />

75<br />

75<br />

100<br />

TYP<br />

150 MAX<br />

AL BEAM<br />

DEPTH<br />

BEAM<br />

2 - 20mm DIA SST<br />

BOLTS (PROVIDE<br />

SHORT HORIZONTAL<br />

SLOTTED HOLES<br />

IN BEAM WEB)<br />

65mm DIMENSION TYPICAL EXCEPT 50mm FOR 100mm BEAMS.<br />

65 65<br />

EXISTING CONCRETE<br />

WALL OR BEAM<br />

175 MIN<br />

EMBED<br />

WHERE BOTH ENDS OF BEAM ARE ATTACHED TO A WALL, PROVIDE LONG HORIZONTALLY<br />

SLOTTED HOLES IN BEAM WEB AT ONE END. TIGHTEN NUTS SNUG TIGHT, BACK OFF 1/2<br />

TURN, AND LOCK WITH DOUBLE NUT.<br />

0514-056<br />

90<br />

150<br />

MIN<br />

MIN, SEE<br />

NOTE 2<br />

SST 150x100x10x75 W/<br />

2 - 20mm DIA SST STUD TYPE<br />

ADHESIVE ANCHORS (70<br />

LENGTH FOR 100 BEAM)<br />

DO NOT CUT EXISTING CONCRETE BEAM TOP REINFORCING DURING DRILL-IN ANCHOR<br />

INSTALLATION. FIELD LOCATE BEAM REINFORCING PRIOR TO FABRICATION. ADD LENGTH<br />

TO CLIP ANGLES AS REQUIRED TO LOWER ANCHORS TO CLEAR REINFORCING WHILE<br />

MAINTAINING SPACING AND EDGE DISTANCE AS SHOWN.<br />

FILENAME: 000-S-5011.dgn PLOT DATE: 2012\07\25 PLOT TIME: 6:17:20 PM<br />

DISTRICT M UNICIPALITY<br />

DATE<br />

PROJ<br />

DWG<br />

OF M USKOKA<br />

SHEET<br />

FAIRYVIEW W ATER TREATMENT PLANT<br />

STRUCTURAL<br />

NTS<br />

MB<br />

07/2012 ISSUED FOR TENDER<br />

AT<br />

0<br />

PHASE I UPGRADES<br />

STANDARD DETAILS (2)<br />

VERIFY SCALE<br />

BAR IS 25mm ON<br />

APVD<br />

BY<br />

REVISION<br />

DATE<br />

NO.<br />

CONTRACT 12-432-253<br />

ORIGINAL DRAWING.<br />

0 25 MM<br />

APVD<br />

CHK<br />

DSGN DR<br />

AT<br />

AT NA<br />

RP<br />

2012/07/27<br />

424251<br />

000-S-5011<br />

04of62 CH2M HILL 2012. ALL RIGHTS RESERVED.<br />

c<br />

THIS DOCUMENT, AND THE IDEAS AND DESIGNS INCORPORATED HEREIN, AS AN INSTRUMENT OF PROFESSIONAL SERVICE, IS THE PROPERTY OF<br />

CH2M HILL AND IS NOT TO BE USED, IN W HOLE OR IN PART, FOR ANY OTHER PROJECT WITHOUT THE W RITTEN AUTHORIZATION OF CH2MHILL.<br />

REUSE OF DOCUMENTS:<br />

ISSUED FOR TENDER

A<br />

B<br />

C<br />

D<br />

HIGH LIFT<br />

PUMP ROOM<br />

EXISTING MONORAIL<br />

1<br />

000-D-5001<br />

REFER TO DWG<br />

C-0001 FOR<br />

CONTINUATION<br />

NOT IN CONTRACT.<br />

REFER TO NOTE 6<br />

NOTES:<br />

REFER TO NOTE 5<br />

4<br />

000-D-2006<br />

HIGH LIFT PUMP DISCHARGE<br />

HEADER AND BYPASS.<br />

REFER TO NOTE 5<br />

3<br />

000-D-2006<br />

DIMENSIONS ARE APPROXIMATE.<br />

SPECIFICATION SECTION 15080.<br />

1 2 3 4 5 6<br />

PHOTO<br />

PHOTO<br />

3<br />

1 2<br />

PHOTOS<br />

100 W1<br />

STAINLESS STEEL PIPING WHERE REQUIRED BEFORE INSULATING.<br />

TO OUTSIDE OF BUILDING IS NOT IN CONTRACT.<br />

CO2 PANEL IS NOT IN CONTRACT.<br />

4<br />

REFER TO DWG<br />

000-M-2007<br />

FOR DETAILS<br />

2<br />

000-D-5001<br />

TYPICAL<br />

1. EXISTING BACKGROUND TAKEN FROM TOTTEN SIMS HUBICKI ASSOCIATES IN ASSOCIATION WITH<br />

RYSCO ENGINEERING CORPORATION. PROJECT 52-6630, DRAWING M3, AS CONSTRUCTED SEPT. 91.<br />

GENERATOR ROOM<br />

EXISTING BACKGROUND HAS BEEN MODIFIED BY CH2M HILL TO SUIT THIS PROJECT. ALL BACKGROUND<br />

2. CONTRACTOR TO VERIFY ALL EXISTING CONDITIONS TO FAMILIARIZE THEMSELVES WITH THE SCOPE<br />

OF WORK PRIOR TO PROCEEDING. SOME PIPING AND EQUIPMENT HAS BEEN OMITTED FOR CLARITY.<br />

3. INSTALL DOUBLE WALL INSULATED AND HEAT TRACED SHX STORAGE TANK ON 50 THICK STYROFOAM<br />

HIGHLOAD EXTRUDED POLYSTYRENE INSULATION RATED FOR A LOAD OF 275 kPa OR GREATER.<br />

4. INSULATE BOOSTER WATER AND CHLORINE SOLUTION PIPING IN CHLORINATOR ROOM PER<br />

5. INSULATE PIPES IN PIPE GALLERY, HIGH LIFT HEADER, DISCHARGE HEADER AND BYPASS IN GENERATOR ROOM.<br />

PROVIDE REMOVABLE INSULATION SECURED WITH VELCRO ADHESIVE AROUND VALVES, EQUIPMENT (EXCLUDING<br />

PUMPS AND AIR/VACUUM RELIEF VALVES), INJECTION POINTS ETC. PER SECTION 15080. CLEAN AND PASSIVATE<br />

6. CAP 25-CD-SST INSIDE OF BUILDING AT CEILING NEAR OUTSIDE WALL. 25-CD-SST THROUGH WALL<br />

7. SEAL 40-SHX-PVC CARRIER PIPE AT CEILING ABOVE SHX STORAGE TANK/PANEL. COIL ADEQUATE<br />

POLYETHYLENE TUBES, HEAT TRACING CABLE, AND PULL STRING AT CEILING (OUTSIDE OF CARRIER PIPE)<br />

TO ALLOW FOR FUTURE CONNECTION TO SHX PANEL (REFER TO DETAIL 2 ON DWG 000-D-5002).<br />

SHX FILL STATION, STORAGE TANK, PANEL, AND INTERCONNECTING PIPING BETWEEN STORAGE TANK<br />

AND PANEL ARE NOT IN CONTRACT. SPILL CONTAINMENT CURBS ARE IN CONTRACT.<br />

8. CAP 25-CD-SST, 65-DWW-PVC, AND 50-CDS-PVC (2 PIPES) AT CEILING ABOVE CO2 PANEL.<br />

9. REFER TO DRAWING 000-A-2001 FOR SHX SPILL CONTAINMENT AREA COATING DETAILS.<br />

PIPE GALLERY<br />

REFER TO NOTE 5 AND DRAWINGS<br />

000-D-2004 AND 000-D-2005<br />

FOR INSULATION DETAILS<br />

1% SLOPE DOWN<br />

25-CD-SST<br />

40-SHX-PVC<br />

2 CONTAINMENT<br />

PIPE<br />

000-D-5002<br />

CHLORINATOR ROOM<br />

PLAN<br />

1:100<br />

FLOOR<br />

NOT IN CONTRACT.<br />

REFER TO NOTE 7<br />

25-CA-SST<br />

1<br />

65-DCW-PVC<br />

LOCATE SHX FILL STATION<br />

ON OUTSIDE OF CONCRETE<br />

CONTAINMENT WALL<br />

(FILL STATION BY LESSOR)<br />

RELOCATE EXISTING CL2 BOOSTER<br />

PUMPS AND PIPING. PROVIDE NEW<br />

CONCRETE BASES TO SUIT. REMOVE<br />

EXISTING CONCRETE BASES AND<br />

RESTORE FLOOR TO MATCH<br />

EXISTING FLOOR. REFER TO<br />

NOTE 4 AND STRUCTURAL<br />

DETAILS<br />

UP TO SECOND<br />

0330-143<br />

0330-056<br />

REPLACE KNIFE GATE AT<br />

BOTTOM OF EXISTING SILO<br />

000-D-2006<br />

SODA ASH ROOM<br />

EXISTING<br />

65 DCW<br />

CHEMICAL STORAGE<br />

REFER TO<br />

NOTE 9<br />

SHX STORAGE TANK.<br />

REFER TO NOTE 3<br />

SHX PANEL. REFER<br />

TO DWG 000-N-0008<br />

FOR PIPING DETAILS<br />

EXISTING LIME<br />

PUMP SKID<br />

CO2 PANEL. REFER<br />

TO DWG 000-N-0007<br />

FOR PIPING DETAILS<br />

40-DCW-PVC<br />

40-LS-PVC<br />

2 LINES<br />

(DUTY/STANDBY)<br />

25-LS-PLY<br />

2 LINES<br />

(DUTY/STANDBY)<br />

FROM LIME PUMP<br />

SKID IN SODA ASH<br />

ROOM<br />

LIME DILUTION PANEL.<br />

REFER TO DWG 000-N-0006<br />

FOR PIPING DETAILS<br />

1<br />

000-D-2007<br />

REFER TO DETAIL 1 ON<br />

DWG 000-D-2007 FOR<br />

CONTINUATION<br />

NOT IN CONTRACT.<br />

REFER TO NOTE 8<br />

4 - CONTINUOUS SPILL<br />

CONTAINMENT CURBS.<br />

OUTSIDE DIMENSIONS<br />

2<br />

ARE 2500 x 4000 000-S-5001<br />

EXISTING 150– HIGH<br />

CONCRETE CURB<br />

AIR DRYER<br />

AIR COMPRESSOR M-9275<br />

FILL EXISTING 150– HIGH CONCRETE<br />

CURB AREA WITH CONCRETE<br />

0330-056<br />

N<br />

DATE<br />

PROJ<br />

SHEET<br />

VERIFY SCALE<br />

FILENAME: 000-D-2001_424251.dgn PLOT DATE: 2012\07\26 PLOT TIME: 8:25:08 AM<br />

DISTRICT M UNICIPALITY<br />

DWG<br />

OF M USKOKA<br />

FAIRYVIEW W ATER TREATMENT PLANT<br />

PROCESS MECHANICAL<br />

MB<br />

JPN<br />

ISSUED FOR TENDER<br />

07/2012<br />

0<br />

PHASE I UPGRADES<br />

BAR IS 25mm ON<br />

APVD<br />

BY<br />

REVISION<br />

DATE<br />

NO.<br />

CONTRACT 12-432-253<br />

GROUND FLOOR PLAN<br />

ORIGINAL DRAWING.<br />

0 25 MM<br />

APVD<br />

CHK<br />

DSGN DR<br />

08of62<br />

ET JPN<br />

JPN RC<br />

2012/07/27<br />

424251<br />

000-D-2001<br />

CH2M HILL 2012. ALL RIGHTS RESERVED.<br />

c<br />

THIS DOCUMENT, AND THE IDEAS AND DESIGNS INCORPORATED HEREIN, AS AN INSTRUMENT OF PROFESSIONAL SERVICE, IS THE PROPERTY OF<br />

CH2M HILL AND IS NOT TO BE USED, IN W HOLE OR IN PART, FOR ANY OTHER PROJECT WITHOUT THE W RITTEN AUTHORIZATION OF CH2MHILL.<br />

REUSE OF DOCUMENTS:<br />

ISSUED FOR TENDER

A<br />

B<br />

C<br />

D<br />

NOTES:<br />

1 2 3 4 5 6<br />

MATCH LINE. REFER TO<br />

DWG 000-D-2003 FOR<br />

CONTINUATION<br />

DIMENSIONS ARE APPROXIMATE.<br />

2. CONTRACTOR TO VERIFY ALL EXISTING CONDITIONS TO FAMILIARIZE<br />

THEMSELVES WITH THE SCOPE OF WORK PRIOR TO PROCEEDING.<br />

SOME PIPING AND EQUIPMENT HAS BEEN OMITTED, FOR CLARITY.<br />

25-CA-SST<br />

DOWN TO<br />

GROUND FLOOR<br />

FLEXIBLE PLASTIC TUBE.<br />

IN ASSOCIATION WITH RYSCO ENGINEERING CORPORATION. PROJECT<br />

PROVIDE QUICK DISCONNECT<br />

TO 25-CA-SST. FIELD RUN TO<br />

PNEUMATIC SILO FLUIDIZERS,<br />

TYPICAL. REFER TO<br />

SPECIFICATIONS FOR<br />

DETAILS<br />

1. EXISTING BACKGROUND TAKEN FROM TOTTEN SIMS HUBICKI ASSOCIATES<br />

52-6630, DRAWING M3, AS CONSTRUCTED SEPT. 91. EXISTING BACKGROUND<br />

HAS BEEN MODIFIED BY CH2M HILL TO SUIT THIS PROJECT. ALL BACKGROUND<br />

REPLACE EXISTING<br />

SILO FILTER<br />

2<br />

000-D-2006<br />

SILO<br />

FOR DETAILS<br />

CLEAN AND REFURBISH<br />

INTERIOR OF SILO.<br />

REFER TO SPECIFICATIONS<br />

UPPER<br />

SODA ASH<br />

ROOM<br />

PROVIDE 18 PNEUMATIC<br />

FLUIDIZERS INSTALLED AS<br />

RECOMMENDED BY<br />

MANUFACTURER. REFER<br />

TO SPECIFICATIONS<br />

PARTIAL PLAN<br />

1:50<br />

MECHANICAL ROOM<br />

REFER TO BUILDING MECHANICAL DRAWINGS<br />

FOR EQUIPMENT IN THIS ROOM<br />

EXISTING LADDER UP TO HIGH<br />

ROOF ACCESS HATCH ABOVE<br />

N<br />

DATE<br />

PROJ<br />

SHEET<br />

VERIFY SCALE<br />

FILENAME: 000-D-2002_424251.dgn PLOT DATE: 2012\07\26 PLOT TIME: 8:25:23 AM<br />

DISTRICT M UNICIPALITY<br />

DWG<br />

OF M USKOKA<br />

FAIRYVIEW W ATER TREATMENT PLANT<br />

PROCESS MECHANICAL<br />

MB<br />

JPN<br />

ISSUED FOR TENDER<br />

07/2012<br />

0<br />

PHASE I UPGRADES<br />

BAR IS 25mm ON<br />

APVD<br />

BY<br />

REVISION<br />

DATE<br />

NO.<br />

CONTRACT 12-432-253<br />

PARTIAL SECOND FLOOR PLAN (1)<br />

ORIGINAL DRAWING.<br />

0 25 MM<br />

APVD<br />

CHK<br />

DSGN DR<br />

424251<br />

09of62<br />

ET JPN<br />

JPN RC<br />

2012/07/27<br />

000-D-2002<br />

CH2M HILL 2012. ALL RIGHTS RESERVED.<br />

c<br />

THIS DOCUMENT, AND THE IDEAS AND DESIGNS INCORPORATED HEREIN, AS AN INSTRUMENT OF PROFESSIONAL SERVICE, IS THE PROPERTY OF<br />

CH2M HILL AND IS NOT TO BE USED, IN W HOLE OR IN PART, FOR ANY OTHER PROJECT WITHOUT THE W RITTEN AUTHORIZATION OF CH2MHILL.<br />

REUSE OF DOCUMENTS:<br />

ISSUED FOR TENDER

A<br />

B<br />

C<br />

D<br />

1 2 3 4 5 6<br />

MATCH LINE. REFER TO DWG<br />

000-D-2002 FOR CONTINUATION<br />

CORRIDOR<br />

FILTER AND TANK AREA<br />

PARTIAL PLAN<br />

1:50<br />

EXISTING pH<br />

SENSOR<br />

EXISTING<br />

CURB<br />

PROVIDE SLOT<br />

IN EDGE OF<br />

COVER FOR<br />

pH SENSOR<br />

CABLE<br />

EXISTING<br />

ACCESS<br />

COVER<br />

300<br />

300<br />

300 150<br />

EXISTING<br />

CURB<br />

REFER TO DWG 000-S-2001<br />

FOR NEW OPEN GRATING<br />

AND RAILING<br />

EDGE OF<br />

ACCESS<br />

OPENING<br />

NOTES:<br />

pH SENSOR AE-1001<br />

SUPPORT ASSEMBLY.<br />

MOUNT BELOW NEW<br />

OPEN GRATING<br />

DIMENSIONS ARE APPROXIMATE.<br />

1<br />

000-D-5002<br />

EXISTING pH SENSOR JUNCTION<br />

BOX AND CONDUIT<br />

REMOVE EXISTING pH SENSOR ASSEMBLY.<br />

RELOCATE EXISTING pH SENSOR JUNCTION<br />

BOX AND CONDUIT TO CLEAR NEW OPEN<br />

GRATING. RECONNECT TO NEW pH SENSOR<br />

AE-1001<br />

pH SENSOR AE-1101<br />

SUPPORT ASSEMBLY.<br />

MOUNT BELOW EXISTING<br />

ACCESS COVER<br />

1<br />

000-D-5002<br />

1. EXISTING BACKGROUND TAKEN FROM TOTTEN SIMS HUBICKI ASSOCIATES<br />

IN ASSOCIATION WITH RYSCO ENGINEERING CORPORATION. PROJECT<br />

52-6630, DRAWING M3, AS CONSTRUCTED SEPT. 91. EXISTING BACKGROUND<br />

HAS BEEN MODIFIED BY CH2M HILL TO SUIT THIS PROJECT. ALL BACKGROUND<br />

2. CONTRACTOR TO VERIFY ALL EXISTING CONDITIONS TO FAMILIARIZE<br />

THEMSELVES WITH THE SCOPE OF WORK PRIOR TO PROCEEDING.<br />

SOME PIPING AND EQUIPMENT HAS BEEN OMITTED, FOR CLARITY.<br />

N<br />

DATE<br />

PROJ<br />

SHEET<br />

VERIFY SCALE<br />

FILENAME: 000-D-2003_424251.dgn PLOT DATE: 2012\07\26 PLOT TIME: 8:25:39 AM<br />

DISTRICT M UNICIPALITY<br />

DWG<br />

OF M USKOKA<br />

FAIRYVIEW W ATER TREATMENT PLANT<br />

PROCESS MECHANICAL<br />

MB<br />

JPN<br />

ISSUED FOR TENDER<br />

07/2012<br />

0<br />

PHASE I UPGRADES<br />

BAR IS 25mm ON<br />

APVD<br />

BY<br />

REVISION<br />

DATE<br />

NO.<br />

CONTRACT 12-432-253<br />

PARTIAL SECOND FLOOR PLAN (2)<br />

ORIGINAL DRAWING.<br />

0 25 MM<br />

APVD<br />

CHK<br />

DSGN DR<br />

424251<br />

10of62<br />

ET JPN<br />

JPN RC<br />

2012/07/27<br />

000-D-2003<br />

CH2M HILL 2012. ALL RIGHTS RESERVED.<br />

c<br />

THIS DOCUMENT, AND THE IDEAS AND DESIGNS INCORPORATED HEREIN, AS AN INSTRUMENT OF PROFESSIONAL SERVICE, IS THE PROPERTY OF<br />

CH2M HILL AND IS NOT TO BE USED, IN W HOLE OR IN PART, FOR ANY OTHER PROJECT WITHOUT THE W RITTEN AUTHORIZATION OF CH2MHILL.<br />

REUSE OF DOCUMENTS:<br />

ISSUED FOR TENDER

A<br />

B<br />

C<br />

D<br />

300X200 RED TEE ON<br />

CONCRETE SUPPORT<br />

4<br />

000-D-2005<br />

REFER TO NOTE 2<br />

1<br />

3<br />

000-D-2005<br />

2<br />

2<br />

REFER TO NOTE 2<br />

PVC ANGLE VALVE<br />

1 2 3 4 5 6<br />

FUTURE CONNECTION<br />

250X200<br />

REDUCER<br />

7<br />

FUTURE 150 DIA<br />

FILTER-TO-WASTE<br />

250X200<br />

REDUCER<br />

7<br />

8<br />

8<br />

1 3<br />

1<br />

3<br />

300X250<br />

REDUCER<br />

300X250<br />

REDUCER<br />

6<br />

9<br />

9<br />

6<br />

REFER TO<br />

NOTE 2<br />

450X200<br />

350X300<br />

ECC RED<br />

REDUCER<br />

5<br />

000-D-2005<br />

350 DIA STRAINER<br />

FLAT ON TOP<br />

2<br />

450X200<br />

REDUCER<br />

PIPE GALLERY<br />

NOTE 2<br />

BLOWER AIR<br />

(NO INSULATION<br />

REQUIRED)<br />

REFER TO<br />

NOTE 2<br />

BLOWER AIR<br />

(NO INSULATION<br />

REQUIRED)<br />

REFER TO<br />

12<br />

5<br />

300 DIA FILTER VENT<br />

4<br />

DRILL 300 DIA BLIND FLG<br />

FOR 75 DIA AIR VALVE<br />

CONNECTION<br />

10<br />

11<br />

REFER TO<br />

NOTE 2<br />

PLAN<br />

1:30<br />

FILTER 4200<br />

150 DIA CONDUIT VENT<br />

FILTER 4100<br />

150 DIA VENT<br />

MIDWAY BETWEEN<br />

TROUGHS<br />

TOP OF CURB<br />

3<br />

9<br />

1 SECTION<br />

1:30<br />

--<br />

BLOWER AIR<br />

(NO INSULATION<br />

REQUIRED)<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

NOTES:<br />

LEGEND<br />

PIPE SUPPORT<br />

1<br />

200 ANGLE GLOBE VALVE<br />

300 SWING-FLEX CHECK VALVE<br />

200 MANUAL BUTTERFLY VALVE (BFV)<br />

300 BFV C/W IQT ACTUATOR<br />

PRESSURE INDICATING TRANSMITTER<br />

200 MAGNETIC FLOW METER<br />

200 BFV C/W ACTUATOR<br />

150 MANUAL BFV<br />

PRESSURE INDICATOR<br />

75 AIR / VACUUM VALVE<br />

12 AIR RELEASE VALVE<br />

300 MAGNETIC FLOW METER (EXISTING FROM DISTRICT)<br />

1. CONTRACTOR TO VERIFY ALL EXISTING CONDITIONS TO FAMILIARIZE<br />

THEMSELVES WITH THE SCOPE OF WORK PRIOR TO PROCEEDING.<br />

SOME PIPING AND EQUIPMENT HAS BEEN OMITTED FOR CLARITY.<br />

2. INSULATE ALL PIPE GALLERY PIPES. PROVIDE REMOVABLE INSULATION<br />

SECURED WITH VELCRO ADHESIVE AROUND VALVES, EQUIPMENT<br />

(EXCLUDING PUMPS AND AIR/VACUUM RELIEF VALVES), INJECTION POINTS<br />

ETC. PER SECTION 15080. CLEAN AND PASSIVATE STAINLESS STEEL PIPING<br />

WHERE REQUIRED BEFORE INSULATING.<br />

DATE<br />

PROJ<br />

SHEET<br />

VERIFY SCALE<br />

FILENAME: 000-D-2004_424251.dgn PLOT DATE: 2012\07\25 PLOT TIME: 5:49:13 PM<br />

DISTRICT M UNICIPALITY<br />

DWG<br />

OF M USKOKA<br />

FAIRYVIEW W ATER TREATMENT PLANT<br />

PROCESS MECHANICAL<br />

MB<br />

JPN<br />

ISSUED FOR TENDER<br />

07/2012<br />

0<br />

PHASE I UPGRADES<br />

BAR IS 25mm ON<br />

APVD<br />

BY<br />

REVISION<br />

DATE<br />

NO.<br />

CONTRACT 12-432-253<br />

PIPE GALLERY INSULATION<br />

PLAN AND SECTION<br />

ORIGINAL DRAWING.<br />

0 25 MM<br />

APVD<br />

CHK<br />

DSGN DR<br />

11of62<br />

ET JPN<br />

JPN RC<br />

2012/07/27<br />

424251<br />

000-D-2004<br />

CH2M HILL 2012. ALL RIGHTS RESERVED.<br />

c<br />

THIS DOCUMENT, AND THE IDEAS AND DESIGNS INCORPORATED HEREIN, AS AN INSTRUMENT OF PROFESSIONAL SERVICE, IS THE PROPERTY OF<br />

CH2M HILL AND IS NOT TO BE USED, IN W HOLE OR IN PART, FOR ANY OTHER PROJECT WITHOUT THE W RITTEN AUTHORIZATION OF CH2MHILL.<br />

REUSE OF DOCUMENTS:<br />

ISSUED FOR TENDER

A<br />

B<br />

C<br />

D<br />

REFER TO<br />

NOTE 2<br />

BLOWER AIR<br />

1 2 3 4 5 6<br />

(NO INSULATION<br />

REQUIRED)<br />

DRILL 300 DIA BLIND FLG<br />

FOR 75 DIA AIR VALVE<br />

CONNECTION<br />

75 DIA GATE VALVE<br />

100X75 REDUCER<br />

100 DIA NIPPLE<br />

300X300 TEE FOR<br />

FUTURE FILTERS<br />

150 DIA VENT<br />

4<br />

11<br />

10<br />

CONCRETE SUPPORT<br />

PIPE SUPPORT<br />

TOP OF CURB<br />

300 DIA VENT<br />

5 5<br />

250 DIA BLIND<br />

FLANGE<br />

2 SECTION<br />

1:30<br />

000-D-2004<br />

REFER TO<br />

NOTE 2<br />

BLOWER AIR<br />

(NO INSULATION<br />

REQUIRED)<br />

UNDERDRAINS<br />

(AWI PHOENIX<br />

LATERALS)<br />

REFER TO<br />

NOTE 2<br />

TOP OF CURB<br />

4 SECTION<br />

1:30<br />

000-D-2004<br />

5<br />

13 MM POTABLE WATER<br />

REFRESH LINE C/W<br />

SOLENOID VALVE WITH<br />

MANUAL BY-PASS VALVES<br />

300 DIA VENT<br />

400X300<br />

REDUCER<br />

400 DIA<br />

FLANGE<br />

450X200<br />

REDUCER<br />

10<br />

6<br />

REFER TO<br />

NOTE 2<br />

6<br />

3 SECTION<br />

1:30<br />

000-D-2004<br />

REFER TO<br />

NOTE 2<br />

7<br />

PIPE SUPPORT<br />

NOTES:<br />

250X200<br />

REDUCER<br />

FUTURE 150 DIA<br />

FILTER-TO-WASTE<br />

11<br />

10<br />

1. CONTRACTOR TO VERIFY ALL EXISTING CONDITIONS TO FAMILIARIZE<br />

THEMSELVES WITH THE SCOPE OF WORK PRIOR TO PROCEEDING.<br />

SOME PIPING AND EQUIPMENT HAS BEEN OMITTED FOR CLARITY.<br />

2. INSULATE ALL PIPE GALLERY PIPES. PROVIDE REMOVABLE INSULATION<br />

SECURED WITH VELCRO ADHESIVE AROUND VALVES, EQUIPMENT<br />

(EXCLUDING PUMPS AND AIR/VACUUM RELIEF VALVES), INJECTION POINTS<br />

ETC. PER SECTION 15080. CLEAN AND PASSIVATE STAINLESS STEEL PIPING<br />

WHERE REQUIRED BEFORE INSULATING.<br />

DATE<br />

PROJ<br />

SHEET<br />

VERIFY SCALE<br />

FILENAME: 000-D-2005_424251.dgn PLOT DATE: 2012\07\25 PLOT TIME: 5:49:28 PM<br />

DISTRICT M UNICIPALITY<br />

DWG<br />

OF M USKOKA<br />

FAIRYVIEW W ATER TREATMENT PLANT<br />

PROCESS MECHANICAL<br />

MB<br />

JPN<br />

ISSUED FOR TENDER<br />

07/2012<br />

0<br />

PHASE I UPGRADES<br />

BAR IS 25mm ON<br />

APVD<br />

BY<br />

REVISION<br />

DATE<br />

NO.<br />

CONTRACT 12-432-253<br />

PIPE GALLERY INSULATION<br />

SECTIONS<br />

ORIGINAL DRAWING.<br />

0 25 MM<br />

APVD<br />

CHK<br />

DSGN DR<br />

12of62<br />

ET JPN<br />

JPN RC<br />

2012/07/27<br />

424251<br />

000-D-2005<br />

CH2M HILL 2012. ALL RIGHTS RESERVED.<br />

c<br />

THIS DOCUMENT, AND THE IDEAS AND DESIGNS INCORPORATED HEREIN, AS AN INSTRUMENT OF PROFESSIONAL SERVICE, IS THE PROPERTY OF<br />

CH2M HILL AND IS NOT TO BE USED, IN W HOLE OR IN PART, FOR ANY OTHER PROJECT WITHOUT THE W RITTEN AUTHORIZATION OF CH2MHILL.<br />

REUSE OF DOCUMENTS:<br />

ISSUED FOR TENDER

A<br />

B<br />

C<br />

D<br />

EXISTING<br />

200 SST PIPE<br />

GENERATOR ROOM<br />

TEMPORARILY DISCONNECT EXISTING<br />

FLUOSILICIC ACID TRANSFER TUBE/PIPE<br />

FROM EXISTING 350 SST DISCHARGE<br />

HEADER. REFER TO PHOTOGRAPH 2<br />

FOR RECONNECTION<br />

EXISTING 350<br />

GATE VALVE<br />

TO REMAIN<br />

REUSE EXISTING<br />

PIPE SUPPORT<br />

1 2 3 4 5 6<br />

1 DETAIL<br />

NTS<br />

000-D-2001<br />

REMOVE EXISTING VENTURI<br />

TRANSMITTER, PIPE BRACKET<br />

SUPPORT, AND CONCRETE BASE.<br />

REFER TO DETAIL<br />

0330-143<br />

ON STRUCTURAL DRAWINGS FOR<br />

CONCRETE BASE REMOVAL<br />

EXISTING SILO<br />

REMOVE EXISTING 200 KNIFE GATE VALVE.<br />

REPLACE WITH 200 ROTARY VALVE.<br />

SHORTEN EXISTING 200 SST PIPE TO SUIT.<br />

REUSE EXISTING EXPANSION JOINTS<br />

EXISTING EXPANSION JOINTS<br />

SODA ASH ROOM<br />

REMOVE EXISTING SECTION OF 40-CLS-PVC<br />

PIPING CONNECTED TO EXISTING 350 SST<br />

DISCHARGE HEADER. PROVIDE 40 NPT SST<br />

PLUG ON NEW SECTION OF 350 SST<br />

DISCHARGE HEADER REFER TO<br />

PHOTOGRAPH 2 FOR RECONNECTION.<br />

SST BYPASS<br />

COUPLING<br />

VENTURI METER AS SHOWN<br />

EXISTING 40-CLS-PVC<br />

EXISTING 350<br />

REUSE EXISTING<br />

350 VICTAULIC<br />

REMOVE EXISTING SECTION OF<br />

350 SST DISCHARGE HEADER AND<br />

GENERATOR ROOM<br />

RECONNECT EXISTING<br />

2 DETAIL<br />

NTS<br />

000-D-2002<br />

FLUOSILICIC ACID TRANSFER<br />

TUBE/PIPE SUPPLY TO NEW<br />

SECTION OF 350 SST DISCHARGE<br />

HEADER. PROVIDE 25 NPT SST<br />

HALF COUPLING ON 350 SST<br />

DISCHARGE HEADER<br />

REFER TO<br />

NOTE 2<br />

REUSE EXISTING<br />

PIPE SUPPORT<br />

4 DETAIL<br />

NTS<br />

000-D-2001<br />

350 SST DISCHARGE<br />

HEADER<br />

REFER TO DWG 000-M-1001<br />

FOR REMOVAL OF EXISTING<br />

SILO FILTER DUCT. DUCT NOT<br />

REQUIRED FOR NEW SILO FILTER<br />

SODA ASH ROOM<br />

REMOVE EXISTING SILO FILTER AND<br />

REPLACE WITH NEW SILO FILTER<br />

EXISTING FLANGE TO REMAIN ON TOP OF<br />

EXISTING SILO. FABRICATE CARBON STEEL<br />

TRANSITION TO CONNECT NEW SILO FILTER<br />

TO EXISTING 1050x1050 FLANGE ON TOP OF<br />

SILO. CONTRACTOR TO VERIFY FLANGE SIZE<br />

AND BOLT PATTERN. REFER TO SECTION 11254<br />

TOP OF EXISTING SILO<br />

EXTEND EXISTING 40-CLS-PVC PIPE TO WALL SIDE EXISTING 40-CLS-PVC<br />

OF 350 SST DISCHARGE HEADER. PROVIDE SST<br />

NPT COUPLING ON 350 SST DISCHARGE HEADER.<br />

PROVIDE BALL VALVE ON CHLORINE PIPE AT 350<br />

SST DISCHARGE HEADER<br />

EXISTING WALL<br />

DEMOLITION (PHOTOGRAPH 1) NEW PIPING (PHOTOGRAPH 2) NEW PIPING (PHOTOGRAPH 3)<br />

EXISTING 350<br />

SST BYPASS<br />

EXISTING 350 VICTAULIC COUPLING<br />

350 MAGNETIC FLOW METER<br />

FE-5001<br />

REFER TO<br />

PHOTOGRAPH 3<br />

FOR CONTINUATION<br />

EXISTING PIPE SUPPORT<br />

REFER TO<br />

PHOTOGRAPH 2<br />

FOR CONTINUATION<br />

PROVIDE 40 NPT SST PLUG FOR<br />

EXISTING COUPLING ON 350 SST<br />

DISCHARGE HEADER<br />

GENERATOR ROOM<br />

REMOVE SECTION OF<br />

EXISTING 25 SST PIPE<br />

IN VERTICAL TO SUIT<br />

CONNECTION OF 2<br />

25-EDW-SST PIPES<br />

EXISTING 350 SST<br />

DISCHARGE<br />

HEADER<br />

NOTES:<br />

25 BACKFLOW 25 GLOBE VALVE 25 CHECK VALVE<br />

PREVENTER<br />

RECIRCULATION<br />

PUMP<br />

PHOTOGRAPH 4<br />

3 DETAIL<br />

NTS<br />

000-D-2001<br />

GENERATOR ROOM<br />

FLOW<br />

25 BALL VALVE<br />

VALVE<br />

EXISTING 350<br />

SST BYPASS<br />

6-SHX-PE<br />

FOR CONTINUATION<br />

CHEMICAL 5<br />

INJECTOR<br />

000-D-5001<br />

REFER TO NOTE 2<br />

THEMSELVES WITH THE SCOPE OF WORK PRIOR TO PROCEEDING.<br />

SOME PIPING AND EQUIPMENT HAS BEEN OMITTED FOR CLARITY.<br />

STAINLESS STEEL PIPING WHERE REQUIRED BEFORE INSULATING.<br />

25-EDW-SST<br />

25 BALL<br />

VALVE<br />

CONNECT 25-EDW-SST<br />

TO EXISTING 25 SST<br />

PIPE BETWEEN EXISTING<br />

TEE AND EXISTING BALL<br />

REFER TO DWG 000-D-2001<br />

000-D-5002<br />

DATE<br />

PROJ<br />

SHEET<br />

VERIFY SCALE<br />

FILENAME: 000-D-2006_424251.dgn PLOT DATE: 2012\07\25 PLOT TIME: 5:49:46 PM<br />

2<br />

PROVIDE 25 SST NPT HALF<br />

COUPLING ON EXISTING<br />

350 SST DISCHARGE<br />

HEADER<br />

1. CONTRACTOR TO VERIFY ALL EXISTING CONDITIONS TO FAMILIARIZE<br />

2. PROVIDE REMOVABLE INSULATION SECURED WITH VELCRO ADHESIVE AROUND<br />

VALVES, EQUIPMENT (EXCLUDING PUMPS AND AIR/VACUUM RELIEF VALVES),<br />

INJECTION POINTS ETC. PER SECTION 15080 FOR ENTIRE LENGTH OF PUMP<br />

DISCHARGE HEADER AND BYPASS IN GENERATOR ROOM. CLEAN AND PASSIVATE<br />

DISTRICT M UNICIPALITY<br />

DWG<br />

OF M USKOKA<br />

FAIRYVIEW W ATER TREATMENT PLANT<br />

PROCESS MECHANICAL<br />

MB<br />

JPN<br />

ISSUED FOR TENDER<br />

07/2012<br />

0<br />

PHASE I UPGRADES<br />

BAR IS 25mm ON<br />

APVD<br />

BY<br />

REVISION<br />

DATE<br />

NO.<br />

CONTRACT 12-432-253<br />

PIPING MODIFICATIONS (1)<br />

ORIGINAL DRAWING.<br />

0 25 MM<br />

APVD<br />

CHK<br />

DSGN DR<br />

13of62<br />

ET JPN<br />

JPN RC<br />

2012/07/27<br />

424251<br />

000-D-2006<br />

CH2M HILL 2012. ALL RIGHTS RESERVED.<br />

c<br />

THIS DOCUMENT, AND THE IDEAS AND DESIGNS INCORPORATED HEREIN, AS AN INSTRUMENT OF PROFESSIONAL SERVICE, IS THE PROPERTY OF<br />

CH2M HILL AND IS NOT TO BE USED, IN W HOLE OR IN PART, FOR ANY OTHER PROJECT WITHOUT THE W RITTEN AUTHORIZATION OF CH2MHILL.<br />

REUSE OF DOCUMENTS:<br />

ISSUED FOR TENDER

A<br />

B<br />

C<br />

D<br />

1 2 3 4 5 6<br />

FLOC TANK No. 3<br />

FLOC TANK No. 1<br />

RAPID MIXING<br />

CHAMBER<br />

CHEMICAL PIPING DEMOLITION<br />

1:50<br />

CHAMBER<br />

REMOVE EXISTING 65 PVC<br />

POLYELECTROLYTES PIPE<br />

EXCEPT FOR PORTION IN<br />

SODA ASH<br />

RETENTION<br />

CHAMBER<br />

SODA ASH<br />

RETENTION<br />

CHAMBER<br />

JANITOR ROOM<br />

EXISTING 40 PVC CHLORINE<br />

CHEMICAL<br />

STORAGE<br />

EXISTING WALL BETWEEN SODA<br />

ASH RETENTION CHAMBER AND<br />

JANITOR ROOM. PROVIDE PVC<br />

CAP ON PIPE ON JANITOR ROOM<br />

SIDE OF WALL ONLY. FILL PIPE<br />

COMPLETELY WITH GROUT FLUSH<br />

WITH SODA ASH RETENTION<br />

CHAMBER WALL<br />

REMOVE EXISTING 65 PVC<br />

SODIUM CARBONATE PIPE<br />

EXCEPT FOR PORTION IN<br />

EXISTING WALL BETWEEN SODA<br />

ASH RETENTION CHAMBER AND<br />

JANITOR ROOM. PROVIDE PVC<br />

CAP ON PIPE ON JANITOR ROOM<br />

SIDE OF WALL ONLY. FILL PIPE<br />

COMPLETELY WITH GROUT FLUSH<br />

WITH SODA ASH RETENTION<br />

CHAMBER WALL<br />

EXISTING CONCRETE BLOCK WALL<br />

COVERING CONCRETE TANK WALL<br />

BETWEEN SODA ASH RETENTION<br />

CHAMBER AND JANITOR ROOM<br />

1<br />

PHOTO<br />

2<br />

PHOTO<br />

SODA ASH MIXING CHAMBER<br />

REMOVE EXISTING 65 PVC<br />

SODIUM CARBONATE PIPING<br />

REMOVE EXISTING 65 PVC<br />

PHOTOGRAPH (JANITOR ROOM)<br />

1 NTS<br />

PROVIDE PVC CAP ON PIPE ON ONE SIDE OF EACH WALL ONLY.<br />

CUT PIPE FLUSH WITH OTHER SIDE OF WALL WHEN REMOVING<br />

PIPE SECTIONS. FILL PIPE WITHIN WALL COMPLETELY WITH<br />

NON-SHRINK, NON-FERROUS GROUT FLUSH WITH OTHER SIDE<br />

OF WALL. REFER TO DETAIL ON THIS DRAWING FOR NEW CHEMICAL<br />

PIPING. ALL REPAIRS TO BE WATER TIGHT<br />

POLYELECTROLYTES PIPING<br />

EXISTING 20 PVC<br />

ALUMINUM SULPHATE<br />

EXISTING 40 PVC CHLORINE<br />

EXISTING CONCRETE<br />

TANK WALL<br />

EXISTING CONCRETE<br />

BLOCK WALL<br />

EXISTING 65 PVC POLYELECTROLYTES<br />

PIPING TERMINATES AT THIS POINT<br />

REMOVE EXISTING 65 PVC<br />

SODIUM CARBONATE PIPE<br />

BACK TO SODA ASH ROOM<br />

EXISTING 20 PVC<br />

ALUMINUM SULPHATE<br />

EXISTING 40 PVC CHLORINE EXISTING 40 PVC CHLORINE<br />

EXISTING 20 PVC<br />

ALUMINUM SULPHATE<br />

REFER TO PHOTOGRAPH 2<br />

FOR CONTINUATION AND<br />

PIPE DEMOLITION DETAILS<br />

THROUGH THIS WALL<br />

EXISTING CONCRETE<br />

BLOCK WALL<br />

1 DETAIL<br />

NTS<br />

000-D-2001<br />

EXISTING CONCRETE<br />

TANK WALL<br />

EXISTING CONCRETE<br />

BLOCK WALL<br />

EXISTING 20 PVC<br />

ALUMINUM SULPHATE<br />

REFER TO PHOTOGRAPH 1<br />

FOR CONTINUATION<br />

REMOVE EXISTING 65 PVC<br />

POLYELECTROLYTES PIPE<br />

AND 65 PVC SODIUM<br />

CARBONATE PIPE ON<br />

BOTH SIDES OF WALL<br />

SEPARATING JANITOR ROOM<br />

AND CHEMICAL STORAGE AS<br />

SHOWN. CUT PIPES FLUSH<br />

WITH WALL ON BOTH SIDES<br />

OF WALL. PIPES TO REMAIN<br />

IN WALL AND WILL BE USED<br />

AS SLEEVES FOR 2 NEW<br />

40-LS-PVC PIPES. REFER TO<br />

"NEW CHEMICAL PIPING" ON<br />

THIS DRAWING FOR ADDITIONAL<br />

DETAILS<br />

EXISTING CONCRETE BLOCK<br />

WALL BETWEEN JANITOR ROOM<br />

AND CHEMICAL STORAGE<br />

2 NTS<br />

FLOC TANK No. 3<br />

FLOC TANK No. 1<br />

1:50<br />

CHAMBER<br />

SODA ASH<br />

RETENTION<br />

CHAMBER<br />

FL EL 293.450<br />

RAPID MIXING<br />

CHAMBER<br />

SODA ASH<br />

RETENTION<br />

CHAMBER<br />

FL EL 293.450<br />

JANITOR ROOM<br />

CHEMICAL<br />

STORAGE<br />

FOR CONTINUATION<br />

1<br />

PHOTO<br />

2<br />

PHOTO<br />

50-CDS-PVC PIPES FROM CO2 PANEL.<br />

REFER TO DWG 000-D-2001<br />

TOC<br />

EL 297.850<br />

NEW CHEMICAL PIPING<br />

PHOTOGRAPH (CHEMICAL STORAGE)<br />

2<br />

000-D-5001<br />

REMOVE EXISTING 65 PVC<br />

SODIUM CARBONATE PIPE<br />

BACK TO SODA ASH ROOM.<br />

RUN 2 NEW 40-LS-PVC PIPES<br />

IN EXISTING PIPE TRAY ALONG<br />

SAME ROUTE AS REMOVED<br />

SODIUM CARBONATE PIPE<br />

NOTES:<br />

50-CDS-PVC<br />

RETENTION CHAMBER<br />

SODA ASH MIXING CHAMBER<br />

EXISTING 20 PVC<br />

ALUMINUM SULPHATE<br />

EXISTING 40 PVC CHLORINE<br />

EXISTING 20 PVC<br />

ALUMINUM SULPHATE<br />

DIMENSIONS ARE APPROXIMATE.<br />

TERMINATE VERTICAL PIPE 500<br />

ABOVE BOTTOM OF SODA ASH<br />

4<br />

000-D-5001<br />

FL EL 293.450<br />

PROVIDE 40 NPT PVC TEE WITH PLUG.<br />

TERMINATE VERTICAL PIPE 1000 ABOVE<br />

SODA ASH MIXING CHAMBER FLOOR<br />

4<br />

000-D-5001<br />

50-CDS-PVC<br />

TERMINATE VERTICAL PIPE 500<br />

ABOVE BOTTOM OF SODA ASH<br />

RETENTION CHAMBER<br />

40-LS-PVC<br />

4<br />

000-D-5001<br />

2 REUSE EXISTING PIPE SLEEVES FROM<br />

SODIUM CARBONATE AND POLYELECTROLYTE<br />

000-D-5001PIPE<br />

REMOVAL DONE UNDER DEMOLITION ON<br />

THIS DRAWING<br />

40-LS-PVC FROM LIME ROOM (2 PIPES).<br />

RUN PIPES IN EXISTING PIPE TRAY<br />

ALONG SAME ROUTE AS REMOVED<br />

SODIUM CARBONATE PIPE. REFER TO<br />

DWG 000-D-2001 FOR CONTINUATION<br />

EXISTING 40 PVC CHLORINE<br />

1. CONTRACTOR TO VERIFY ALL EXISTING CONDITIONS TO FAMILIARIZE<br />

THEMSELVES WITH THE SCOPE OF WORK PRIOR TO PROCEEDING.<br />

SOME PIPING AND EQUIPMENT HAS BEEN OMITTED, FOR CLARITY.<br />

2. EXISTING BACKGROUND TAKEN FROM TOTTEN SIMS HUBICKI ASSOCIATES<br />

IN ASSOCIATION WITH RYSCO ENGINEERING CORPORATION. PROJECT<br />

52-6630, DRAWING M3, AS CONSTRUCTED SEPT. 91. EXISTING BACKGROUND<br />

HAS BEEN MODIFIED BY CH2M HILL TO SUIT THIS PROJECT. ALL BACKGROUND<br />

DATE<br />

PROJ<br />

SHEET<br />

VERIFY SCALE<br />

FILENAME: 000-D-2007_424251.dgn PLOT DATE: 2012\07\26 PLOT TIME: 8:25:55 AM<br />

DISTRICT M UNICIPALITY<br />

DWG<br />

OF M USKOKA<br />

FAIRYVIEW W ATER TREATMENT PLANT<br />

PROCESS MECHANICAL<br />

MB<br />

JPN<br />

ISSUED FOR TENDER<br />

07/2012<br />

0<br />

PHASE I UPGRADES<br />

BAR IS 25mm ON<br />

APVD<br />

BY<br />

REVISION<br />

DATE<br />

NO.<br />

CONTRACT 12-432-253<br />

PIPING MODIFICATIONS (2)<br />

ORIGINAL DRAWING.<br />

0 25 MM<br />

APVD<br />

CHK<br />

DSGN DR<br />

14of62<br />

ET JPN<br />

JPN RC<br />

2012/07/27<br />

424251<br />

000-D-2007<br />

CH2M HILL 2012. ALL RIGHTS RESERVED.<br />

c<br />

THIS DOCUMENT, AND THE IDEAS AND DESIGNS INCORPORATED HEREIN, AS AN INSTRUMENT OF PROFESSIONAL SERVICE, IS THE PROPERTY OF<br />

CH2M HILL AND IS NOT TO BE USED, IN W HOLE OR IN PART, FOR ANY OTHER PROJECT WITHOUT THE W RITTEN AUTHORIZATION OF CH2MHILL.<br />

REUSE OF DOCUMENTS:<br />

ISSUED FOR TENDER

A<br />

B<br />

C<br />

D<br />

SST PIPE<br />

ENDS AS<br />

SHOWN<br />

ON PLANS<br />

AS REQUIRED FOR<br />

PIPE INSTALLATION,<br />

230 MINIMUM<br />

SEAL WELD<br />

AROUND<br />

BOTH SIDES<br />

NOTE:<br />

1<br />

-<br />

C L WALL<br />

0330-022<br />

REFER TO DETAIL ON STRUCTURAL<br />

DRAWINGS FOR PENETRATING EXISTING WALLS.<br />

CORE DRILL HOLE PIPE<br />

OD + 65. CLEAN PRIOR<br />

TO INSTALLING AND<br />

GROUTING PIPE.<br />

PROVIDE NON-SHRINK,<br />

NON-FERROUS GROUT<br />

NOTES:<br />

1 2 3 4 5 6<br />

STAINLESS STEEL WALL PIPE<br />

150 MIN<br />

50<br />

EXISTING<br />

DETAIL<br />

NTS<br />

CONCRETE<br />

WALL<br />

150 MIN<br />

125<br />

SST SEEP RING 6<br />

MINIMUM THICKNESS<br />

D<br />

230 MINIMUM<br />

D+50 THRU 300<br />

D+100 350 AND<br />

LARGER<br />

AS REQUIRED FOR<br />

PIPE INSTALLATION,<br />

12.7 THICK PVC ROUND FLANGE<br />

WELDED TO PIPE<br />

GASKET<br />

0330-022<br />

1. REFER TO DETAIL ON STRUCTURAL<br />

DRAWINGS FOR PENETRATING EXISTING WALLS.<br />

6 - 12.7 DIAMETER IDENTICAL CONCRETE<br />

ADHESIVE ANCHORS AND WASHERS<br />

EQUALLY RADIALLY SPACED<br />

PVC PIPE<br />

12.7 THICK - 40H NEOPRENE<br />

2. "WATER SIDE" IS DEEMED TO BE IN THE "SODA ASH MIXING CHAMBER"<br />

CHAMBERS ON DWG 000-D-2007.<br />

4 DETAIL<br />

NTS<br />

-<br />

INSIDE FACE OF WALL (WATER SIDE).<br />

REFER TO NOTE 2<br />

AND THE "CHAMBER" FOR WALL PENETRATIONS BETWEEN THE<br />

PVC PIPE THROUGH EXISTING WALL<br />

UNINSULATED PIPE INSULATED PIPE<br />

E<br />

ESCUTCHEON PLATE,<br />

TYP<br />

PIPE<br />

SIZE<br />

FILL SOLID WITH<br />

FIRE STOP<br />

INSULATION<br />

NON-SHRINK<br />

NON-FERROUS<br />

GROUT<br />

NOTES:<br />

1. PROVIDE GALVANIZED SCH.10 STEEL PIPE SLEEVE. WHEN THE<br />

PIPE IS SPECIFIED AS STAINLESS STEEL USE A STAINLESS<br />

STEEL PIPE SLEEVE (SCH 10).<br />

2. PIPE SLEEVE AND NON-SHRINK, NON-FERROUS GROUT NOT<br />

REQUIRED IF CORE DRILLING AN EXISTING CONCRETE WALL.<br />

3. ENSURE THAT PIPE SLEEVE IS PROVIDED WHEN PASSING<br />

THROUGH NEW OR EXISTING BLOCK/BRICK WALLS.<br />

RUN SLEEVE ENTIRE WIDTH OF WALL.<br />

0330-022<br />

4. REFER TO DETAIL ON STRUCTURAL<br />

DRAWINGS FOR PENETRATING EXISTING WALLS.<br />

INJECTOR<br />

ASSEMBLY<br />

PIPING THROUGH WALLS<br />

MPT HOSE<br />

BARB TYP<br />

BOTH ENDS<br />

OF HOSE<br />

A<br />

D<br />

ISOLATION<br />

VALVE<br />

2 DETAIL<br />

NTS<br />

-<br />

SST RESTRAINT HOOK<br />

MPT INLET CONNECTION<br />

BALL VALVE SIZED TO<br />

PASS SOLUTION TUBE<br />

INTEGRAL SPRING LOADED<br />

BALL CHECK VALVE<br />

SPECIFIC NOTES:<br />

SST HOSE<br />

CLAMP (TYP)<br />

NOTE 3<br />

B<br />

C<br />

FLEXIBLE<br />

HOSE<br />

GENERAL NOTES:<br />

NOTE 1<br />

SOLUTION<br />

TUBE<br />

ADAPTER<br />

PACKING NUT<br />

SST SAFETY CHAIN<br />

(LIMIT CHAIN)<br />

NEW<br />

CONCRETE<br />

WALL<br />

PIPE SLEEVE<br />

(SEE NOTE)<br />

INSULATION &<br />

JACKETING<br />

SEALANT,<br />

TYP<br />

EXISTING<br />

CONCRETE<br />

WALL<br />

D<br />

PENETRATION = DIA / 2,<br />

45<br />

BEVEL<br />

NOTE 2<br />

SOLUTION<br />

TUBE<br />

WITH MAX PENETRATION OF<br />

600 FOR PIPE LARGER THAN<br />

1200<br />

I SEE CHEMICAL INJECTION SCHEDULES IN THIS DETAIL.<br />

II DETAIL SUITABLE FOR FEED PUMP MAX RELIEF<br />

PRESSURE OF 1034 kPa, MAIN LINE PRESSURE<br />

690kPa OR LESS, AND FEED LINE 25 OR LESS.<br />

1. UNLESS OTHERWISE NOTED, PROVIDE SST SERVICE SADDLE FOR DUCTILE<br />

IRON (1050 MAX). PROVIDE OUTLET / TAPPING SADDLE FOR 1200 TO 1370 DUCTILE<br />

IRON. FOR CARBON STEEL AND SST PIPE (900 MAX), PROVIDE THREADOLET,<br />

SAME MATERIAL AS PIPE. FOR CARBON STEEL AND SST PIPE (1050 - 1800), PROVIDE<br />

WELDED NOZZLE SAME MATERIAL AS PIPE. FOR CARBON STEEL AND SST PIPE<br />

WITH INTERIOR COATING, WELD FITTINGS IN FACTORY PRIOR TO APPLYING<br />

INTERIOR COATING. FOR PVC, PROVIDE REDUCED TEE FITTING.<br />

2. ORIENT BEVEL SO IT FACES FLOW DIRECTION. SEE VENDOR’S RECOMMENDATIONS.<br />

3. PROVIDE 12x6 TUBE REDUCER UPSTREAM OF ISOLATION VALVE "A"<br />

5<br />

-<br />

DETAIL<br />

NTS<br />

FLOOR<br />

COMPONENT<br />

MARK<br />

A<br />

B<br />

C<br />

D<br />

E<br />

FLOW<br />

STREAM<br />

FL<br />

SH<br />

SBS<br />

SHC<br />

FC<br />

AL<br />

PP<br />

X<br />

X<br />

X<br />

NOTE:<br />

NOTE:<br />

6 THICK<br />

x 50 SEEP<br />

RING<br />

3 DETAIL<br />

NTS<br />

-<br />

PROCESS PIPE SIZE AND<br />

MATERIAL AS SHOWN<br />

ON DRAWINGS<br />

FIRE STOP<br />

SEALANT, TYP<br />

UNDERSIDE OF FLOOR<br />

STAINLESS STEEL PIPE<br />

TO SUIT (PIPE OD + 50)<br />

FOAMING MATERIAL OR<br />

COMPRESSED SEALER<br />

PIPE SLEEVE THROUGH INTERIOR FLOOR<br />

SCHEDULE 1 - CHEMICAL INJECTOR DEFAULT COMPONENTS<br />

ALUM, 48%<br />

COMPONENT DESCRIPTION<br />

ISOLATION VALVE<br />

FLEXIBLE HOSE<br />

SOLUTION TUBE<br />

ISOLATION VALVE<br />

SOLUTION TUBE AND INTEGRAL<br />

SPRING LOADED BALL CHECK<br />

VALVE WITH TEFLON BALL<br />

INJECTOR ASSEMBLY INCLUDES<br />

B C D AND ANCILLARIES<br />

SCHEDULE 2 - COMPONENTS BY CHEMICAL<br />

DESCRIPTION<br />

(NOTE 1)<br />

HYDROFLUOSILICIC ACID, 25-35%<br />

SODIUM HYDROXIDE, 30-70%<br />

SODIUM BISULFITE, 38%<br />

SODIUM HYPOCHLORITE, 12%<br />

FERRIC CHLORIDE, 40%<br />

POTASSIUM PERMANGANATE,<br />

10%<br />

CORROSION INHIBITOR<br />

(ORTHO-PHOSPHATES)<br />

FERRIC SULFATE, 40%<br />

POLYMER<br />

(CATIONIC AND ANIONIC)<br />