Drawings - Peak Engineering and Construction Ltd

Drawings - Peak Engineering and Construction Ltd

Drawings - Peak Engineering and Construction Ltd

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

A<br />

B<br />

C<br />

D<br />

HIGH LIFT<br />

PUMP ROOM<br />

EXISTING MONORAIL<br />

1<br />

000-D-5001<br />

REFER TO DWG<br />

C-0001 FOR<br />

CONTINUATION<br />

NOT IN CONTRACT.<br />

REFER TO NOTE 6<br />

NOTES:<br />

REFER TO NOTE 5<br />

4<br />

000-D-2006<br />

HIGH LIFT PUMP DISCHARGE<br />

HEADER AND BYPASS.<br />

REFER TO NOTE 5<br />

3<br />

000-D-2006<br />

DIMENSIONS ARE APPROXIMATE.<br />

SPECIFICATION SECTION 15080.<br />

1 2 3 4 5 6<br />

PHOTO<br />

PHOTO<br />

3<br />

1 2<br />

PHOTOS<br />

100 W1<br />

STAINLESS STEEL PIPING WHERE REQUIRED BEFORE INSULATING.<br />

TO OUTSIDE OF BUILDING IS NOT IN CONTRACT.<br />

CO2 PANEL IS NOT IN CONTRACT.<br />

4<br />

REFER TO DWG<br />

000-M-2007<br />

FOR DETAILS<br />

2<br />

000-D-5001<br />

TYPICAL<br />

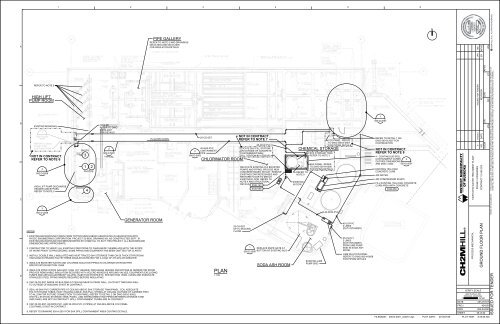

1. EXISTING BACKGROUND TAKEN FROM TOTTEN SIMS HUBICKI ASSOCIATES IN ASSOCIATION WITH<br />

RYSCO ENGINEERING CORPORATION. PROJECT 52-6630, DRAWING M3, AS CONSTRUCTED SEPT. 91.<br />

GENERATOR ROOM<br />

EXISTING BACKGROUND HAS BEEN MODIFIED BY CH2M HILL TO SUIT THIS PROJECT. ALL BACKGROUND<br />

2. CONTRACTOR TO VERIFY ALL EXISTING CONDITIONS TO FAMILIARIZE THEMSELVES WITH THE SCOPE<br />

OF WORK PRIOR TO PROCEEDING. SOME PIPING AND EQUIPMENT HAS BEEN OMITTED FOR CLARITY.<br />

3. INSTALL DOUBLE WALL INSULATED AND HEAT TRACED SHX STORAGE TANK ON 50 THICK STYROFOAM<br />

HIGHLOAD EXTRUDED POLYSTYRENE INSULATION RATED FOR A LOAD OF 275 kPa OR GREATER.<br />

4. INSULATE BOOSTER WATER AND CHLORINE SOLUTION PIPING IN CHLORINATOR ROOM PER<br />

5. INSULATE PIPES IN PIPE GALLERY, HIGH LIFT HEADER, DISCHARGE HEADER AND BYPASS IN GENERATOR ROOM.<br />

PROVIDE REMOVABLE INSULATION SECURED WITH VELCRO ADHESIVE AROUND VALVES, EQUIPMENT (EXCLUDING<br />

PUMPS AND AIR/VACUUM RELIEF VALVES), INJECTION POINTS ETC. PER SECTION 15080. CLEAN AND PASSIVATE<br />

6. CAP 25-CD-SST INSIDE OF BUILDING AT CEILING NEAR OUTSIDE WALL. 25-CD-SST THROUGH WALL<br />

7. SEAL 40-SHX-PVC CARRIER PIPE AT CEILING ABOVE SHX STORAGE TANK/PANEL. COIL ADEQUATE<br />

POLYETHYLENE TUBES, HEAT TRACING CABLE, AND PULL STRING AT CEILING (OUTSIDE OF CARRIER PIPE)<br />

TO ALLOW FOR FUTURE CONNECTION TO SHX PANEL (REFER TO DETAIL 2 ON DWG 000-D-5002).<br />

SHX FILL STATION, STORAGE TANK, PANEL, AND INTERCONNECTING PIPING BETWEEN STORAGE TANK<br />

AND PANEL ARE NOT IN CONTRACT. SPILL CONTAINMENT CURBS ARE IN CONTRACT.<br />

8. CAP 25-CD-SST, 65-DWW-PVC, AND 50-CDS-PVC (2 PIPES) AT CEILING ABOVE CO2 PANEL.<br />

9. REFER TO DRAWING 000-A-2001 FOR SHX SPILL CONTAINMENT AREA COATING DETAILS.<br />

PIPE GALLERY<br />

REFER TO NOTE 5 AND DRAWINGS<br />

000-D-2004 AND 000-D-2005<br />

FOR INSULATION DETAILS<br />

1% SLOPE DOWN<br />

25-CD-SST<br />

40-SHX-PVC<br />

2 CONTAINMENT<br />

PIPE<br />

000-D-5002<br />

CHLORINATOR ROOM<br />

PLAN<br />

1:100<br />

FLOOR<br />

NOT IN CONTRACT.<br />

REFER TO NOTE 7<br />

25-CA-SST<br />

1<br />

65-DCW-PVC<br />

LOCATE SHX FILL STATION<br />

ON OUTSIDE OF CONCRETE<br />

CONTAINMENT WALL<br />

(FILL STATION BY LESSOR)<br />

RELOCATE EXISTING CL2 BOOSTER<br />

PUMPS AND PIPING. PROVIDE NEW<br />

CONCRETE BASES TO SUIT. REMOVE<br />

EXISTING CONCRETE BASES AND<br />

RESTORE FLOOR TO MATCH<br />

EXISTING FLOOR. REFER TO<br />

NOTE 4 AND STRUCTURAL<br />

DETAILS<br />

UP TO SECOND<br />

0330-143<br />

0330-056<br />

REPLACE KNIFE GATE AT<br />

BOTTOM OF EXISTING SILO<br />

000-D-2006<br />

SODA ASH ROOM<br />

EXISTING<br />

65 DCW<br />

CHEMICAL STORAGE<br />

REFER TO<br />

NOTE 9<br />

SHX STORAGE TANK.<br />

REFER TO NOTE 3<br />

SHX PANEL. REFER<br />

TO DWG 000-N-0008<br />

FOR PIPING DETAILS<br />

EXISTING LIME<br />

PUMP SKID<br />

CO2 PANEL. REFER<br />

TO DWG 000-N-0007<br />

FOR PIPING DETAILS<br />

40-DCW-PVC<br />

40-LS-PVC<br />

2 LINES<br />

(DUTY/STANDBY)<br />

25-LS-PLY<br />

2 LINES<br />

(DUTY/STANDBY)<br />

FROM LIME PUMP<br />

SKID IN SODA ASH<br />

ROOM<br />

LIME DILUTION PANEL.<br />

REFER TO DWG 000-N-0006<br />

FOR PIPING DETAILS<br />

1<br />

000-D-2007<br />

REFER TO DETAIL 1 ON<br />

DWG 000-D-2007 FOR<br />

CONTINUATION<br />

NOT IN CONTRACT.<br />

REFER TO NOTE 8<br />

4 - CONTINUOUS SPILL<br />

CONTAINMENT CURBS.<br />

OUTSIDE DIMENSIONS<br />

2<br />

ARE 2500 x 4000 000-S-5001<br />

EXISTING 150– HIGH<br />

CONCRETE CURB<br />

AIR DRYER<br />

AIR COMPRESSOR M-9275<br />

FILL EXISTING 150– HIGH CONCRETE<br />

CURB AREA WITH CONCRETE<br />

0330-056<br />

N<br />

DATE<br />

PROJ<br />

SHEET<br />

VERIFY SCALE<br />

FILENAME: 000-D-2001_424251.dgn PLOT DATE: 2012\07\26 PLOT TIME: 8:25:08 AM<br />

DISTRICT M UNICIPALITY<br />

DWG<br />

OF M USKOKA<br />

FAIRYVIEW W ATER TREATMENT PLANT<br />

PROCESS MECHANICAL<br />

MB<br />

JPN<br />

ISSUED FOR TENDER<br />

07/2012<br />

0<br />

PHASE I UPGRADES<br />

BAR IS 25mm ON<br />

APVD<br />

BY<br />

REVISION<br />

DATE<br />

NO.<br />

CONTRACT 12-432-253<br />

GROUND FLOOR PLAN<br />

ORIGINAL DRAWING.<br />

0 25 MM<br />

APVD<br />

CHK<br />

DSGN DR<br />

08of62<br />

ET JPN<br />

JPN RC<br />

2012/07/27<br />

424251<br />

000-D-2001<br />

CH2M HILL 2012. ALL RIGHTS RESERVED.<br />

c<br />

THIS DOCUMENT, AND THE IDEAS AND DESIGNS INCORPORATED HEREIN, AS AN INSTRUMENT OF PROFESSIONAL SERVICE, IS THE PROPERTY OF<br />

CH2M HILL AND IS NOT TO BE USED, IN W HOLE OR IN PART, FOR ANY OTHER PROJECT WITHOUT THE W RITTEN AUTHORIZATION OF CH2MHILL.<br />

REUSE OF DOCUMENTS:<br />

ISSUED FOR TENDER