Drawings - Peak Engineering and Construction Ltd

Drawings - Peak Engineering and Construction Ltd

Drawings - Peak Engineering and Construction Ltd

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

A<br />

B<br />

C<br />

D<br />

R<br />

D<br />

M<br />

H<br />

F<br />

I<br />

P<br />

DP<br />

T<br />

SD<br />

FD<br />

CO<br />

2<br />

FSD<br />

1 2 3 4 5 6<br />

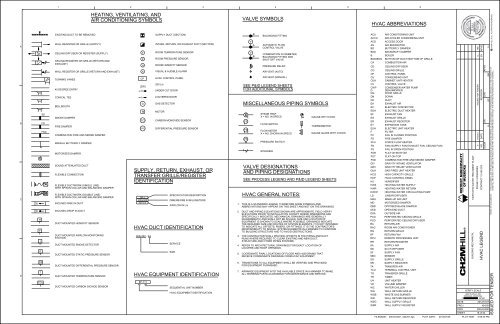

EXISTING DUCT TO BE REMOVED<br />

WALL REGISTER OR GRILLE (SUPPLY)<br />

CEILING DIFFUSER OR REGISTER (SUPPLY)<br />

CEILING REGISTER OR GRILLE (RETURN AND<br />

EXHAUST)<br />

WALL REGISTER OR GRILLE (RETURN AND EXHAUST)<br />

TURNING VANES<br />

45 DEGREE ENTRY<br />

CONICAL TEE<br />

BELLMOUTH<br />

SMOKE DAMPER<br />

FIRE DAMPER<br />

COMBINATION FIRE AND SMOKE DAMPER<br />

MANUAL BUTTERFLY DAMPER<br />

MOTORIZED DAMPER<br />

SOUND ATTENUATED DUCT<br />

FLEXIBLE CONNECTION<br />

FLEXIBLE DUCTWORK (SINGLE LINE)<br />

WITH SPIN-IN COLLAR AND BALANCING DAMPER<br />

FLEXIBLE DUCTWORK (DOUBLE LINE)<br />

WITH SPIN-IN COLLAR AND BALANCING DAMPER<br />

INCLINED RISE IN DUCT<br />

INCLINED DROP IN DUCT<br />

DUCT-MOUNTED HUMIDITY SENSOR<br />

DUCT-MOUNTED AIRFLOW MONITORING<br />

STATION<br />

DUCT-MOUNTED SMOKE DETECTOR<br />

DUCT-MOUNTED STATIC PRESSURE SENSOR<br />

DUCT-MOUNTED DIFFERENTIAL PRESSURE SENSOR<br />

DUCT-MOUNTED TEMPERATURE SENSOR<br />

DUCT-MOUNTED CARBON DIOXIDE SENSOR<br />

HEATING, VENTILATING, AND<br />

AIR CONDITIONING SYMBOLS<br />

T<br />

P<br />

H<br />

A<br />

CP<br />

(200)<br />

U<br />

L<br />

G<br />

EF-111<br />

SUPPLY DUCT (SECTION)<br />

INTAKE, RETURN, OR EXHAUST DUCT (SECTION)<br />

ROOM TEMPERATURE SENSOR<br />

ROOM PRESSURE SENSOR<br />

ROOM HUMIDITY SENSOR<br />

HVAC CONTROL PANEL<br />

200 L/s<br />

M MOTOR<br />

VISUAL & AUDIBLE ALARM<br />

UNDER CUT DOOR<br />

LOUVERED DOOR<br />

GAS DETECTOR<br />

CO CARBON MONOXIDE SENSOR<br />

DPS DIFFERENTIAL PRESSURE SENSOR<br />

SUPPLY, RETURN, EXHAUST, OR<br />

TRANSFER GRILLE/REGISTER<br />

IDENTIFICATION<br />

SR-1<br />

300x300<br />

300 L/s<br />

HVAC DUCT IDENTIFICATION<br />

600x300 - EA<br />

SPECIFICATION DESCRIPTION<br />

DIMENSIONS IN MILLIMETERS<br />

AIRFLOW IN L/s<br />

SERVICE<br />

SIZE<br />

HVAC EQUIPMENT IDENTIFICATION<br />

SEQUENTIAL UNIT NUMBER<br />

HVAC EQUIPMENT IDENTIFICATION<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

6.<br />

7.<br />

VALVE SYMBOLS<br />

FS<br />

X<br />

FM<br />

X<br />

PS<br />

F<br />

F<br />

B<br />

A<br />

B<br />

BALANCING FITTING<br />

AUTOMATIC FLOW<br />

CONTROL VALVE<br />

COMBINATION FLOWMETER,<br />

BALANCING FITTING AND<br />

SHUT-OFF VALVE<br />

PRESSURE RELIEF<br />

AIR VENT (AUTO)<br />

AIR VENT (MANUAL)<br />

SEE P&ID LEGEND SHEETS<br />

FOR ADDITIONAL SYMBOLS<br />

MISCELLANEOUS PIPING SYMBOLS<br />

STEAM TRAP<br />

X = NO. IN SPECS<br />

FLOW SWITCH<br />

FLOW METER<br />

X = NO. SHOWN IN SPECS<br />

PRESSURE SWITCH<br />

STRAINER<br />

VALVE DESIGNATIONS<br />

AND PIPING DESIGNATIONS<br />

GAUGE WITH COCK<br />

THERMOMETER<br />

GAUGE GLASS WITH COCKS<br />

SEE PROCESS LEGEND AND P&ID LEGEND SHEETS<br />

HVAC GENERAL NOTES:<br />

THIS IS A STANDARD LEGEND. THEREFORE SOME SYMBOLS AND<br />

ABBREVIATIONS MAY APPEAR ON THIS SHEET AND NOT ON THE DRAWINGS.<br />

DUCT AND PIPING ELEVATIONS SHOWN ARE APPROXIMATE. FIELD VERIFY<br />

ELEVATIONS PRIOR TO INSTALLATION. EXCEPT WHERE DIMENSIONS ARE<br />

SPECIFICALLY INDICATED, MECHANICAL DRAWINGS ARE GENERALLY<br />

DIAGRAMMATIC AND SHALL NOT BE SCALED. SIZE AND LOCATION OF<br />

EQUIPMENT IS SHOWN TO SCALE WHERE POSSIBLE. DRAWINGS INDICATE<br />

THE REQUIRED SIZE AND ROUTES OF SYSTEM ELEMENTS. IT IS NOT INTENDED<br />

TO INDICATE ALL OFFSETS, RISERS, OR FITTINGS. IT IS THE CONTRACTOR’S<br />

RESPONSIBILITY TO INSTALL SYSTEM ELEMENTS IN A MANNER TO CONFORM<br />

TO BUILDING STRUCTURE AND TO AVOID OBSTRUCTIONS.<br />

THE CONTRACTOR SHALL PROVIDE OFFSETS IN THE PIPING AND DUCT<br />

RUNS WHERE REQUIRED TO CLEAR EXISTING AND NEW DUCT,<br />

STRUCTURE AND OTHER PIPING SYSTEMS.<br />

REFER TO ARCHITECTURAL DRAWINGS FOR EXACT LOCATION OF<br />

LOUVERS AND ROOF OPENINGS.<br />

COORDINATE FINAL LOCATIONS OF FLOOR AND HUB DRAINS THAT<br />

RECEIVE CONDENSATE DRAINAGE FROM HVAC EQUIPMENT.<br />

TRANSITIONS TO ALL EQUIPMENT SHALL BE VERIFIED AND PROVIDED<br />

FOR EQUIPMENT FURNISHED.<br />

ARRANGE EQUIPMENT INTO THE AVAILABLE SPACE IN A MANNER TO MAKE<br />

ALL WORKING PARTS ACCESSIBLE FOR MAINTENANCE AND SERVICE.<br />

HVAC ABBREVIATIONS<br />

ACU<br />

ACCU AIR-COOLED CONDENSING UNIT<br />

BD<br />

BDD BACKDRAFT DAMPER<br />

B BOILER<br />

CA COMBUSTION AIR<br />

CD<br />

CUH<br />

CWP<br />

DG<br />

EDH<br />

BUTTERFLY DAMPER<br />

CEILING DIFFUSER<br />

CABINET UNIT HEATER<br />

CONDENSER WATER PUMP<br />

DOOR GRILLE<br />

EA EXHAUST AIR<br />

EC ELECTRIC CONVECTOR<br />

ELECTRIC DUCT HEATER<br />

ET EXPANSION TANK<br />

FC FAIL IN CLOSED POSITION<br />

FD FIRE DAMPER<br />

FO FAIL IN OPEN POSITION<br />

FSD COMBINATION FIRE AND SMOKE DAMPER<br />

GRAVITY RELIEF VENTILATOR<br />

HCG HIGH CAPACITY GRILLE<br />

HCP HVAC CONTROL PANEL<br />

HWCP<br />

LD LINEAR DIFFUSER<br />

OBD OPPOSED BLADE DAMPER<br />

OUTSIDE AIR<br />

PCG PERFORATED CEILING GRILLE<br />

PCD PERFORATED CEILING DIFFUSER<br />

RA RETURN AIR<br />

RAC ROOM AIR CONDITIONER<br />

SA SUPPLY AIR<br />

AIR CONDITIONING UNIT<br />

ACD ACCESS DOOR<br />

AS AIR SEPARATOR<br />

BOD/BOG BOTTOM OF DUCT/ BOTTOM OF GRILLE<br />

CG CEILING GRILLE<br />

CP CONTROL PANEL<br />

CU CONDENSING UNIT<br />

CV CONTROL VALVE<br />

D DEHUMIDIFIER<br />

DN DOWN<br />

DU DUCT<br />

EF EXHAUST FAN<br />

EG EXHAUST GRILLE<br />

ER<br />

F FILTER<br />

FN<br />

FOB FLAT ON BOTTOM<br />

FOT FLAT ON TOP<br />

GIV<br />

GRV<br />

GRAVITY INTAKE VENTILATOR<br />

GUH GAS FIRED UNIT HEATER<br />

OED OPEN END DUCT<br />

RG<br />

RR<br />

SD SLOT DIFFUSER<br />

SG<br />

SR<br />

TCU TERMINAL CONTROL UNIT<br />

TG TRANSFER GRILLE<br />

TR TIMER<br />

VD VOLUME DAMPER<br />

WC WATER CHILLER<br />

WG<br />

WGB WASTE GAS BURNER<br />

WR<br />

WSG<br />

EXHAUST REGISTER<br />

EUH ELECTRIC UNIT HEATER<br />

FFH FORCE FLOW HEATER<br />

HU HUMIDIFIER<br />

HWS<br />

HWR<br />

MAU<br />

MD MOTORIZED DAMPER<br />

OSA<br />

RETURN GRILLE<br />

RPU REMOTE PROCESSING UNIT<br />

SEN SENSOR<br />

FAN (SUPPLY FAN EXHAUST FAN, CEILING FAN)<br />

HEATING WATER SUPPLY<br />

HEATING WATER RETURN<br />

HEATING WATER CIRCULATING PUMP<br />

MAKE-UP AIR UNIT<br />

RF RETURN FAN<br />

RETURN REGISTER<br />

SF SUPPLY FAN<br />

SUPPLY GRILLE<br />

SUPPLY REGISTER<br />

TA TRANSFER AIR<br />

UH UNIT HEATER<br />

WALL RETURN GRILLE<br />

WALL RETURN REGISTER<br />

WALL SUPPLY GRILLE<br />

WSR WALL SUPPLY REGISTER<br />

DATE<br />

PROJ<br />

SHEET<br />

VERIFY SCALE<br />

FILENAME: 000-M-0001_424251.dgn PLOT DATE: 2012\07\25 PLOT TIME: 5:59:35 PM<br />

DISTRICT M UNICIPALITY<br />

DWG<br />

OF M USKOKA<br />

FAIRYVIEW W ATER TREATMENT PLANT<br />

BUILDING MECHANICAL<br />

MB<br />

07/2012 ISSUED FOR TENDER<br />

LL<br />

0<br />

PHASE I UPGRADES<br />

BAR IS 25mm ON<br />

APVD<br />

BY<br />

REVISION<br />

DATE<br />

NO.<br />

CONTRACT 12-432-253<br />

HVAC LEGEND<br />

ORIGINAL DRAWING.<br />

0 25 MM<br />

APVD<br />

CHK<br />

DSGN DR<br />

424251<br />

000-M-0001<br />

18of62 LL<br />

SW<br />

KF<br />

LL<br />

2012/07/27<br />

CH2M HILL 2012. ALL RIGHTS RESERVED.<br />

c<br />

THIS DOCUMENT, AND THE IDEAS AND DESIGNS INCORPORATED HEREIN, AS AN INSTRUMENT OF PROFESSIONAL SERVICE, IS THE PROPERTY OF<br />

CH2M HILL AND IS NOT TO BE USED, IN W HOLE OR IN PART, FOR ANY OTHER PROJECT WITHOUT THE W RITTEN AUTHORIZATION OF CH2MHILL.<br />

REUSE OF DOCUMENTS:<br />

ISSUED FOR TENDER