Die Plansee-Gruppe 2011

Die Plansee-Gruppe 2011

Die Plansee-Gruppe 2011

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Ceratizit Hardmetals & Tools<br />

Asian market share expanded Highlights<br />

In the <strong>2011</strong>/12 fiscal year, Ceratizit was able to benefit<br />

significantly from the strong growth of the hard materials<br />

market. This growth was driven by the automotive, food,<br />

aerospace, mechanical engineering and power engineering<br />

industries.<br />

Ceratizit expanded its market share in Asia significantly<br />

by integrating the Taiwanese hard materials manufacturer<br />

CB-Carbide and increasing its production capacity for<br />

tungsten carbide and carbide rods in China.<br />

In fall <strong>2011</strong>, Ceratizit showcased numerous innovative<br />

tools for the cutting tools industry at EMO, the sector’s<br />

largest trade fair. These included new wear-protection<br />

solutions that deliver more robust operations and extend<br />

service life in areas such as thermal processing, wood<br />

pellet production and semiconductor wafer production.<br />

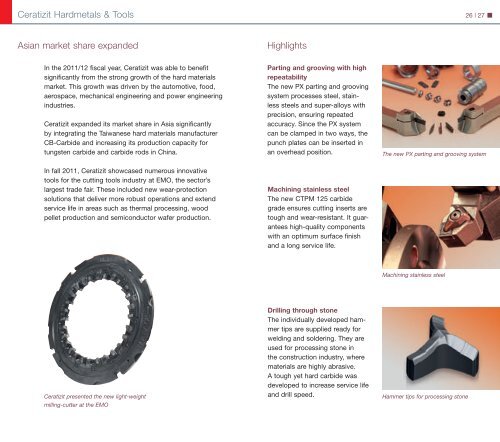

Ceratizit presented the new light-weight<br />

milling-cutter at the EMO<br />

26 | 27<br />

Parting and grooving with high<br />

repeatability<br />

The new PX parting and grooving<br />

system processes steel, stainless<br />

steels and super-alloys with<br />

precision, ensuring repeated<br />

accuracy. Since the PX system<br />

can be clamped in two ways, the<br />

punch plates can be inserted in<br />

an overhead position. The new PX parting and grooving system<br />

Machining stainless steel<br />

The new CTPM 125 carbide<br />

grade ensures cutting inserts are<br />

tough and wear-resistant. It guarantees<br />

high-quality components<br />

with an optimum surface finish<br />

and a long service life.<br />

Drilling through stone<br />

The individually developed hammer<br />

tips are supplied ready for<br />

welding and soldering. They are<br />

used for processing stone in<br />

the construction industry, where<br />

materials are highly abrasive.<br />

A tough yet hard carbide was<br />

developed to increase service life<br />

and drill speed.<br />

Machining stainless steel<br />

Hammer tips for processing stone