Die & Mould Making - CNC - Computer Numerical Control

Die & Mould Making - CNC - Computer Numerical Control

Die & Mould Making - CNC - Computer Numerical Control

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Grey cast-iron<br />

There is a large range of grey cast-irons<br />

with varying tensile strengths. The silicon<br />

content/sectional area combinations form<br />

various structures of which the low-silicon,<br />

fine graphite and pearlite make the<br />

strongest and toughest material. Tensile<br />

strength varies considerably throughout<br />

the range. A coarse graphite structure<br />

means a weaker type. A typical cast-iron,<br />

where metal cutting is involved, often has<br />

a silicon content of around 2%. Common<br />

are the austenitic types.<br />

Nodular cast-iron (SG)<br />

The graphite is contained as round nodules.<br />

Magnesium especially is used to deposit<br />

the gobules and added to become a magnesium-nickel<br />

alloy. Tensile strength, toughness<br />

and ductility are considerably improved.<br />

Ferritic, pearlitic and martensitic<br />

types with various tensile strengths occur.<br />

The SG cast-iron is also a graphite structure<br />

with properties in-between that of grey<br />

and nodular cast-iron. The graphite flakes<br />

are compacted into short ones with round<br />

ends through the addition of titanium and<br />

other treatment.<br />

Malleable cast-iron<br />

When white iron is heat treated in a particular<br />

way, ferritic, pearlitic or martensitic<br />

malleable cast-iron is formed. The heat<br />

treatments may turn the cementite into<br />

spherical carbon particles or remove the<br />

carbides. The cast-iron product is malleable,<br />

ductile and very strong. The silicon<br />

content is low. Three categories occur:<br />

ferritic, pearlitic and martensitic and they<br />

may also be categorized as Blackheart,<br />

Whiteheart and pearlitic.<br />

Alloyed cast-iron<br />

These are cast-irons containing larger<br />

amounts of alloying elements and, generally,<br />

these have similar effects on properties of<br />

cast-iron as they do on steel. Alloying elements<br />

are used to improve properties by<br />

affecting structures. Nickel, chromium,<br />

molybdenum, vanadium and copper are<br />

common ones. The graphite-free white<br />

cast-iron is extremely wear resistant while<br />

the graphite-containing cast-iron is also<br />

known as heat resistant ductile cast-iron.<br />

Corrosion resistance is also improved in<br />

some types. Toughness, hardness and heat<br />

resistance are typically improved.<br />

The main difference in these types is the<br />

form in which carbon, mainly graphite<br />

occurs.<br />

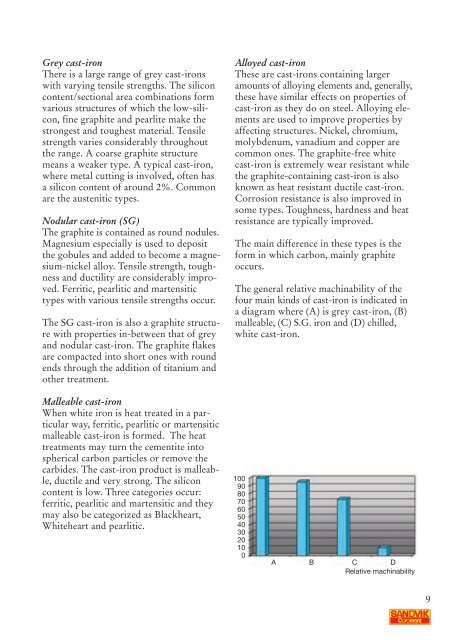

The general relative machinability of the<br />

four main kinds of cast-iron is indicated in<br />

a diagram where (A) is grey cast-iron, (B)<br />

malleable, (C) S.G. iron and (D) chilled,<br />

white cast-iron.<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

A B C D<br />

Relative machinability<br />

9