- Page 1 and 2: APPLICATION GUIDE Die & Mould Makin

- Page 3 and 4: 2 INTRODUCTION Within the die and m

- Page 5 and 6: 4 When a tool has to be made, for i

- Page 7 and 8: 6 CAST-IRON Cast-iron is an ironcar

- Page 9 and 10: 8 Hardness of cast iron-is often me

- Page 11 and 12: 10 Machinability of cast-iron When

- Page 13 and 14: 12 Materiel type Grey Cast-iron All

- Page 15 and 16: 14 The next step is to start up the

- Page 18 and 19: The die for a cutting tool after ma

- Page 20 and 21: This often means that very versatil

- Page 22 and 23: If adding, totally, some 50 hours o

- Page 24 and 25: THE VERSATILITY OF ROUND INSERT CUT

- Page 26 and 27: APPLICATION TECHNOLOGY This is very

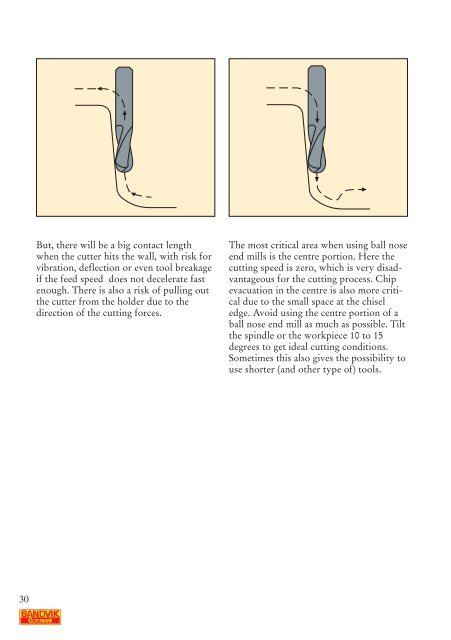

- Page 28 and 29: When doing side milling (finishing)

- Page 32 and 33: For a good tool life it is also mor

- Page 34 and 35: PITCH A B A milling cutter, being a

- Page 36 and 37: When there is a problem with vibrat

- Page 38 and 39: The basic action to take when there

- Page 40 and 41: cut. A 32 mm CoroMill 200 cutter wi

- Page 42 and 43: The aluminium workpiece in the pict

- Page 44 and 45: Vibration severity [mm/s] 4.0 3.0 2

- Page 46 and 47: When planning for HSM one should st

- Page 48 and 49: MACHINING IN SEGMENTS When machinin

- Page 50 and 51: • The remaining stock in the corn

- Page 52 and 53: C D a continuous cutting. When taki

- Page 54 and 55: There are a lot of questions about

- Page 56 and 57: computers and accessories 1,5 years

- Page 58 and 59: adii should always be done to creat

- Page 60 and 61: ae: 0,1-0,2 mm, fz: 0,02-0,2 mm/z T

- Page 62 and 63: Injection moulds and blow moulds ar

- Page 64 and 65: Fc [N] 2500 2000 1500 1000 500 0 0

- Page 66 and 67: m = 0.015 kg v = 84 m/s n = 40,000

- Page 68 and 69: Profile depth Surface with (red lin

- Page 70 and 71: CAD geometry principle e.g. NURBS C

- Page 72 and 73: Pol1 CAM machine-independent machin

- Page 74 and 75: Programmed feedrate F Programmed fe

- Page 76 and 77: Cutting fluid in milling Modern cem

- Page 78 and 79: The best way to ensure a perfect ch

- Page 80 and 81:

light cutting action is needed smal

- Page 82 and 83:

The last parameter to be discussed

- Page 84 and 85:

Basically, CVD coating is done thro

- Page 86 and 87:

GC4030 is also capable of milling h

- Page 88 and 89:

Start values for cutting speed (m/m

- Page 90 and 91:

The third operation is machining de

- Page 92 and 93:

A 3 mm thick carbide shim supports

- Page 94 and 95:

CoroMill 200 Round insert cutters c

- Page 96 and 97:

Cutter body The CoroMill 200 has be

- Page 98 and 99:

CoroMill 390 CoroMill 390 is a high

- Page 100 and 101:

CoroMill 290 Traditionally square s

- Page 102 and 103:

BALL NOSE ENDMILL R216 The ball nos

- Page 104 and 105:

SOLID CARBIDE ENDMILLS Especially i

- Page 106 and 107:

R216.32-N R216.32-N R216.33-N R216.

- Page 108 and 109:

DRILLING TOOLS FOR DIES AND MOULDS

- Page 110 and 111:

Small hole diameters Regrindable dr

- Page 112 and 113:

Deep hole drilling Deep hole drilli

- Page 114 and 115:

Connectors are available for both r

- Page 116 and 117:

A E F G B C D 115

- Page 118 and 119:

It takes less than 20 seconds to ch

- Page 120 and 121:

Transmission torque comparison [Nm]

- Page 122 and 123:

HSK is a spindle interface and not

- Page 124 and 125:

Comparison between holders for clam

- Page 126 and 127:

ROUGHING OF CAVITY RECOMMENDED METH

- Page 128 and 129:

SEMI-FINISHING RECOMMENDED METHOD C

- Page 130 and 131:

ROUGHING COMMON METHOD Roughing of

- Page 132 and 133:

ROUGHING COMMON METHOD Roughing of

- Page 134 and 135:

SEMI-FINISHING COMMON METHOD Contou

- Page 136 and 137:

FINISHING BOTH METHODS Contouring,

- Page 138 and 139:

MACHINING EXAMPLE Machining of thin

- Page 140 and 141:

MACHINING EXAMPLE Roughing of cavit

- Page 142 and 143:

MACHINING EXAMPLE Roughing of press

- Page 144 and 145:

MACHINING EXAMPLE Roughing of die f

- Page 146 and 147:

MACHINING EXAMPLE Roughing of press

- Page 148 and 149:

MACHINING EXAMPLE Semi-finishing of

- Page 150 and 151:

MACHINING EXAMPLE Semi-finishing an

- Page 152 and 153:

MACHINING EXAMPLE Slotmilling of in

- Page 154 and 155:

MACHINING EXAMPLE Semi-finishing of

- Page 156 and 157:

MACHINING EXAMPLE Slotmilling of di

- Page 158 and 159:

MACHINING EXAMPLE Facemilling of pr

- Page 160 and 161:

MACHINING EXAMPLE Drilling through

- Page 162 and 163:

MACHINING EXAMPLE Drilling of holes

- Page 164 and 165:

MACHINING EXAMPLE Deep hole drillin

- Page 166 and 167:

TROUBLE SHOOTING Problem: The machi

- Page 168 and 169:

TROUBLE SHOOTING - SOLID CARBIDE EN

- Page 170 and 171:

THERMAL CRACKS Tool wear Possible c

- Page 172 and 173:

CONSTANT K FOR USE IN POWER REQUIRE

- Page 174 and 175:

Basic grades 4040 1025 3040 530 SM3

- Page 176 and 177:

BASIC GRADES 4030 4040 H13A 690 CB5

- Page 178 and 179:

Basic grades 4040 1025 3040 530 SM3

- Page 180 and 181:

BASIC GRADES 4040 H13A Feed/tooth (

- Page 182 and 183:

SOLID ENDMILLS High speed machining

- Page 184 and 185:

MATERIAL CROSS REFERENCE LIST ISO P

- Page 186 and 187:

ISO Coromant Material Classifi- Cou

- Page 188 and 189:

. . . . . . . . . . . . . . . . . .