Die & Mould Making - CNC - Computer Numerical Control

Die & Mould Making - CNC - Computer Numerical Control

Die & Mould Making - CNC - Computer Numerical Control

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

50<br />

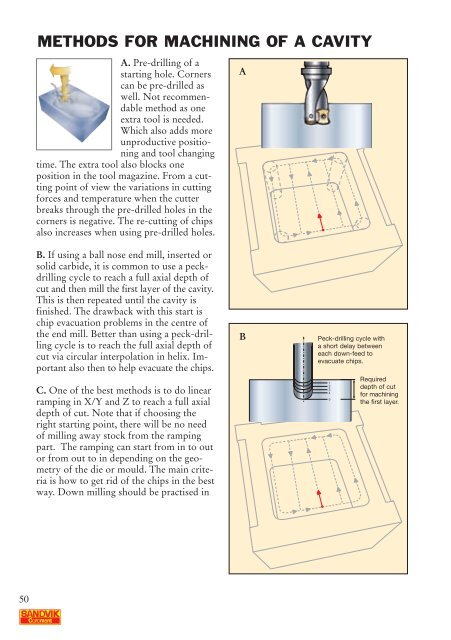

METHODS FOR MACHINING OF A CAVITY<br />

A. Pre-drilling of a<br />

starting hole. Corners<br />

can be pre-drilled as<br />

well. Not recommendable<br />

method as one<br />

extra tool is needed.<br />

Which also adds more<br />

unproductive positioning<br />

and tool changing<br />

time. The extra tool also blocks one<br />

position in the tool magazine. From a cutting<br />

point of view the variations in cutting<br />

forces and temperature when the cutter<br />

breaks through the pre-drilled holes in the<br />

corners is negative. The re-cutting of chips<br />

also increases when using pre-drilled holes.<br />

B. If using a ball nose end mill, inserted or<br />

solid carbide, it is common to use a peckdrilling<br />

cycle to reach a full axial depth of<br />

cut and then mill the first layer of the cavity.<br />

This is then repeated until the cavity is<br />

finished. The drawback with this start is<br />

chip evacuation problems in the centre of<br />

the end mill. Better than using a peck-drilling<br />

cycle is to reach the full axial depth of<br />

cut via circular interpolation in helix. Important<br />

also then to help evacuate the chips.<br />

C. One of the best methods is to do linear<br />

ramping in X/Y and Z to reach a full axial<br />

depth of cut. Note that if choosing the<br />

right starting point, there will be no need<br />

of milling away stock from the ramping<br />

part. The ramping can start from in to out<br />

or from out to in depending on the geometry<br />

of the die or mould. The main criteria<br />

is how to get rid of the chips in the best<br />

way. Down milling should be practised in<br />

A<br />

B<br />

Peck-drilling cycle with<br />

a short delay between<br />

each down-feed to<br />

evacuate chips.<br />

1<br />

2<br />

3<br />

4<br />

5<br />

Required<br />

depth of cut<br />

for machining<br />

the first layer.