Die & Mould Making - CNC - Computer Numerical Control

Die & Mould Making - CNC - Computer Numerical Control

Die & Mould Making - CNC - Computer Numerical Control

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

32<br />

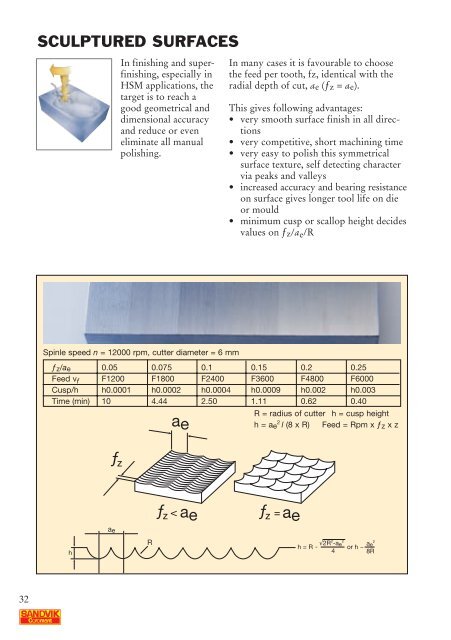

SCULPTURED SURFACES<br />

In finishing and superfinishing,<br />

especially in<br />

HSM applications, the<br />

target is to reach a<br />

good geometrical and<br />

dimensional accuracy<br />

and reduce or even<br />

eliminate all manual<br />

polishing.<br />

Spinle speed n = 12000 rpm, cutter diameter = 6 mm<br />

ƒz/ae<br />

Feed v f<br />

Cusp/h<br />

Time (min)<br />

h<br />

0.05<br />

F1200<br />

h0.0001<br />

10<br />

ae<br />

0.075<br />

F1800<br />

h0.0002<br />

4.44<br />

R<br />

0.1<br />

F2400<br />

h0.0004<br />

2.50<br />

In many cases it is favourable to choose<br />

the feed per tooth, fz, identical with the<br />

radial depth of cut, ae (ƒz = ae).<br />

This gives following advantages:<br />

• very smooth surface finish in all directions<br />

• very competitive, short machining time<br />

• very easy to polish this symmetrical<br />

surface texture, self detecting character<br />

via peaks and valleys<br />

• increased accuracy and bearing resistance<br />

on surface gives longer tool life on die<br />

or mould<br />

• minimum cusp or scallop height decides<br />

values on ƒz/ae/R<br />

0.15<br />

F3600<br />

h0.0009<br />

1.11<br />

0.2<br />

F4800<br />

h0.002<br />

0.62<br />

h = R - √2R2 -ae 2<br />

4<br />

0.25<br />

F6000<br />

h0.003<br />

0.40<br />

R = radius of cutter h = cusp height<br />

h = ae 2 l (8 x R) Feed = Rpm x ƒz x z<br />

or h ~ ae2<br />

8R