Die & Mould Making - CNC - Computer Numerical Control

Die & Mould Making - CNC - Computer Numerical Control

Die & Mould Making - CNC - Computer Numerical Control

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

FROM QUOTATION TO A FINISHED PRESS TOOL<br />

Finding good solutions<br />

with little material<br />

First of all the die and<br />

mouldmaker has to do<br />

a quotation on the<br />

job, which can be hard<br />

many times since the<br />

blueprints from the<br />

customer often is<br />

pretty rough outlined due to their own<br />

ongoing development of the product.<br />

Often the tool maker receive CAD drawings<br />

of the finished component, which looks<br />

far from the different tools that has to be<br />

manufactured to produce the component.<br />

This phenomenon has much to do with<br />

the integration of computers within the<br />

manufacturing and the companies ever<br />

shortened lead times on products.<br />

There are often complicated shapes and<br />

geometries with deep cavities and radii,<br />

which has to be pressed to close tolerances.<br />

To be able to create these shapes several<br />

different press tools has to be manufactured.<br />

If one company can come up with a<br />

smart solution that has fewer steps in the<br />

pressing process they have a clear advantage.<br />

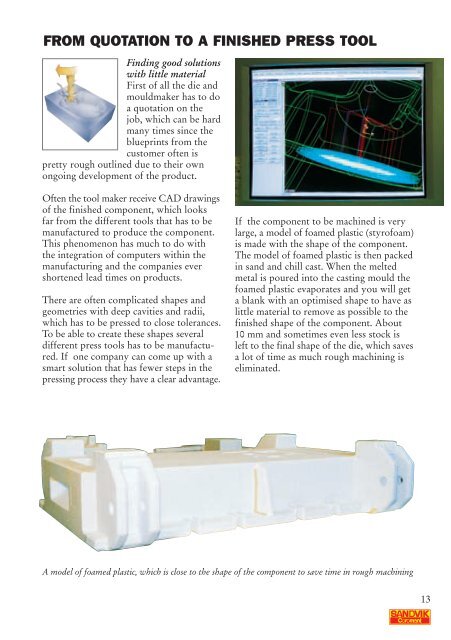

If the component to be machined is very<br />

large, a model of foamed plastic (styrofoam)<br />

is made with the shape of the component.<br />

The model of foamed plastic is then packed<br />

in sand and chill cast. When the melted<br />

metal is poured into the casting mould the<br />

foamed plastic evaporates and you will get<br />

a blank with an optimised shape to have as<br />

little material to remove as possible to the<br />

finished shape of the component. About<br />

10 mm and sometimes even less stock is<br />

left to the final shape of the die, which saves<br />

a lot of time as much rough machining is<br />

eliminated.<br />

A model of foamed plastic, which is close to the shape of the component to save time in rough machining<br />

13