Hydraulic presses and fully automatic press systems for

Hydraulic presses and fully automatic press systems for

Hydraulic presses and fully automatic press systems for

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

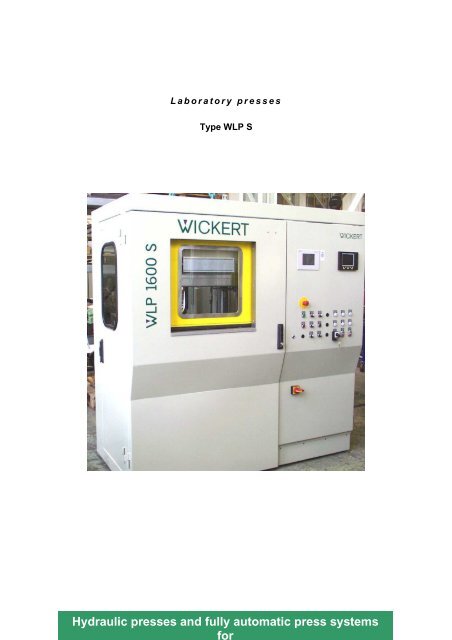

Laboratory <strong><strong>press</strong>es</strong><br />

Type WLP S<br />

<strong>Hydraulic</strong> <strong><strong>press</strong>es</strong> <strong>and</strong> <strong>fully</strong> <strong>automatic</strong> <strong>press</strong> <strong>systems</strong><br />

<strong>for</strong>

Rubber Plastics Brake<br />

linings <strong>and</strong><br />

clutch<br />

linings<br />

Rubber<br />

The WLP S is a special <strong>press</strong> <strong>for</strong> use in laboratories.<br />

A planned modular system makes adaptation to your individual task requirements.<br />

Pressing is done alternatively:<br />

heated<br />

heated / cooled<br />

Plastics<br />

Laboratory<br />

<strong><strong>press</strong>es</strong><br />

Chemistry<br />

Paper<br />

More than st<strong>and</strong>ard !<br />

The data described following is our st<strong>and</strong>ard.<br />

Additionally we offer modified st<strong>and</strong>ard <strong>and</strong> customized solutions.<br />

Powder Laboratorie<br />

s<br />

Others

Technical description Laboratory <strong>press</strong> Type WLP S<br />

Benefits<br />

Repeated consistency of <strong>press</strong>ing <strong>for</strong>ce adjustment<br />

Homogeneous temperature distribution<br />

Good heating up ratio<br />

Rapid cooling<br />

Modular concept based on module system<br />

Use of high-quality st<strong>and</strong>ard components<br />

Reliable machine construction made in Germany<br />

Description<br />

1.) Mechanic<br />

Press engineered as an up-stroke column type with easy access<br />

Clamping system <strong>fully</strong> hydraulic, with quick-fill action with rapid closing <strong>and</strong><br />

opening cylinders<br />

Main piston made of solid gravity die cast<br />

Sealing of the main ram with wear-resistant lip seals, use of guiding strips<br />

<strong>and</strong> dirt scrapers<br />

Leakage oil feedback <strong>for</strong> the main cylinder, no cleaning necessary<br />

Pressure plates made of solid rolled steel, deflection resistant, <strong>for</strong> constant<br />

<strong>press</strong>ure distribution<br />

Heating plates in quality steel, machined out of solid blocks, wear-resistant<br />

Heat insulating plates high-<strong>press</strong>ure resistant, without asbestos, grounded<br />

both sides

2.) Electric<br />

PLC-control, manufacturer: Siemens, type<br />

S7<br />

Control cabinet right side of <strong>press</strong><br />

Control buttons, control lights <strong>and</strong><br />

emergency-off<br />

Selector switch <strong>for</strong> h<strong>and</strong>- <strong>and</strong> <strong>automatic</strong><br />

operation <strong>and</strong> setting<br />

Operating Panel MP 277, 10“, colour<br />

Internal memory store <strong>for</strong> machine<br />

programs<br />

„Press-easy“, the intuitive <strong>press</strong> software<br />

Temperature control executed as software<br />

controller in the CPU of the SPS-control,<br />

set point adjuster <strong>and</strong> actual value indication in plaintext, free choice of<br />

tolerance range up <strong>and</strong> down <strong>for</strong> each temperature value<br />

3.) <strong>Hydraulic</strong><br />

<strong>Hydraulic</strong> drive<br />

<strong>Hydraulic</strong> drive by silently running axial piston pump<br />

Proportional control with integrated closed loop <strong>press</strong>ure control<br />

Proportional flow control<br />

Subsystem including a preload <strong>and</strong><br />

unload manifold to provide a rising or<br />

falling <strong>for</strong>ce characteristic<br />

All functions of the <strong>press</strong> are controlled<br />

right out of the pump <strong>and</strong> ensures<br />

highest reproducibility

<strong>Hydraulic</strong> control<br />

<strong>Hydraulic</strong> control of compact design<br />

Press safety system according to EN 289 designed as a high integrated<br />

manifold<br />

Designed <strong>for</strong> easy maintenance<br />

Leakage-free connection system <strong>for</strong> all piping <strong>and</strong> connections<br />

Noise optimised pump <strong>for</strong> den Laboratory use<br />

Filter<br />

High <strong>press</strong>ure<br />

Return<br />

Intake air<br />

each 10 µm<br />

4.) Safety<br />

1 pneumatically driven protective cover, in the front<br />

integrated in a swivelling safety device in the front, which can be swivelled<br />

easily <strong>for</strong> maintenance <strong>and</strong> cleaning.<br />

Pressing area observable through safety glass<br />

Protective fence outright with accessibility <strong>for</strong> maintenance

OPTIONS<br />

5.) Heating-/cooling plates in special design (<strong>for</strong> design heated/cooled)<br />

Rapid heating with 2-stage-heating <strong>and</strong><br />

cooling with central channel system<br />

Energy efficient heating cartridge, long life<br />

Energy saving <strong>and</strong> improved temperature<br />

distribution by all round insulation of heating<br />

platen<br />

Supply <strong>and</strong> return of cooling medium via stainless steel hoses <strong>and</strong> piping<br />

collecting columns, quantitative flow meter control<br />

Optimised temperature distribution over the heating platen surface by 6<br />

additional control zones<br />

Technical data:<br />

Control accuracy ± 0,5 °C<br />

Temperature distribution 1) ± 1,0 °C<br />

1) Without a margin area of 50 mm, measured at 160 °C.

6.) Heating platens with advanced temperature accuracy<br />

alternative<br />

a) 6-zones-closed-loop-control “electric”<br />

of optimising of the temperature distribution of the heating plates<br />

surface<br />

Optimisation adjustments <strong>for</strong> product or mould<br />

Temperature control by software control<br />

in the CPU of the SPS control, scheduled setting <strong>and</strong> actual value<br />

indicated in plaintext, temperature b<strong>and</strong> up <strong>and</strong> down freely selectable<br />

<strong>for</strong> any temperature<br />

Technical data:<br />

Control accuracy ± 0.1 °C<br />

Temperature distribution 1) ± 1.0 °C<br />

1) Without a margin area of 50 mm, measured at 160 °C.

alternative<br />

b) Advanced 6-zones-closed-loop-control “electric”<br />

Technical data:<br />

Control accuracy ± 0.1 °C<br />

Temperature distribution 1) ± 0.5 °C<br />

c) Advanced 6-zones-closed-loop-control “steam”<br />

Technical data:<br />

Control accuracy ± 0.1 °C<br />

Temperature distribution 1) ± 0.5 °C<br />

Simply ask <strong>for</strong> our extensive range of options <strong>and</strong> accessories to suit your<br />

application.<br />

1) Without a margin area of 50 mm, measured at 160 °C.<br />

1) Without a margin area of 50 mm, measured at 160 °C.

Technical data<br />

Laboratory <strong><strong>press</strong>es</strong><br />

WLP S 230 400 800 1600 3000<br />

Pressing <strong>for</strong>ce kN 230 400 800 1 600 3 000<br />

Heating plate<br />

dimension (W*D) mm² 200 x 200 300 x 300 400 x 400 500 x 400 600 x 600<br />

Daylight mm 135 300 300 300 300<br />

Piston stroke mm 135 300 300 300 300<br />

More than st<strong>and</strong>ard!<br />

Technical data above are our st<strong>and</strong>ard.<br />

Additionally we offer modified st<strong>and</strong>ard <strong>and</strong> customized solutions.