USF RO ManualOMRX_6.pdf

USF RO ManualOMRX_6.pdf

USF RO ManualOMRX_6.pdf

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

RX Manual 04/04 Rev. 6 OPERATING INSTRUCTIONS<br />

Use this section for daily startup or to restart the system after a short-term shutdown.<br />

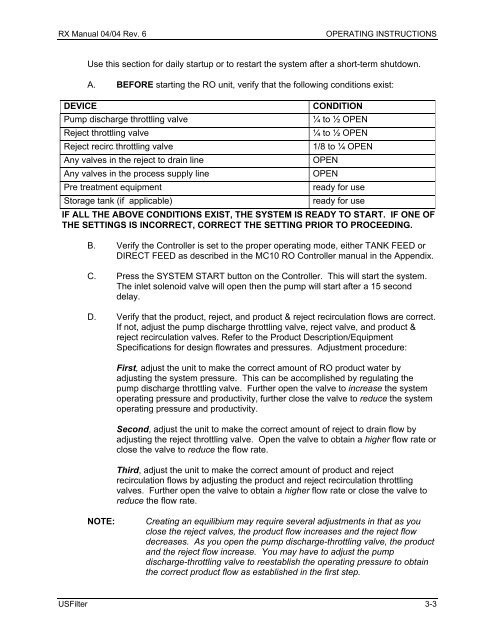

A. BEFORE starting the <strong>RO</strong> unit, verify that the following conditions exist:<br />

DEVICE CONDITION<br />

Pump discharge throttling valve ¼ to ½ OPEN<br />

Reject throttling valve ¼ to ½ OPEN<br />

Reject recirc throttling valve 1/8 to ¼ OPEN<br />

Any valves in the reject to drain line OPEN<br />

Any valves in the process supply line OPEN<br />

Pre treatment equipment ready for use<br />

Storage tank (if applicable) ready for use<br />

IF ALL THE ABOVE CONDITIONS EXIST, THE SYSTEM IS READY TO START. IF ONE OF<br />

THE SETTINGS IS INCORRECT, CORRECT THE SETTING PRIOR TO P<strong>RO</strong>CEEDING.<br />

B. Verify the Controller is set to the proper operating mode, either TANK FEED or<br />

DIRECT FEED as described in the MC10 <strong>RO</strong> Controller manual in the Appendix.<br />

C. Press the SYSTEM START button on the Controller. This will start the system.<br />

The inlet solenoid valve will open then the pump will start after a 15 second<br />

delay.<br />

D. Verify that the product, reject, and product & reject recirculation flows are correct.<br />

If not, adjust the pump discharge throttling valve, reject valve, and product &<br />

reject recirculation valves. Refer to the Product Description/Equipment<br />

Specifications for design flowrates and pressures. Adjustment procedure:<br />

First, adjust the unit to make the correct amount of <strong>RO</strong> product water by<br />

adjusting the system pressure. This can be accomplished by regulating the<br />

pump discharge throttling valve. Further open the valve to increase the system<br />

operating pressure and productivity, further close the valve to reduce the system<br />

operating pressure and productivity.<br />

Second, adjust the unit to make the correct amount of reject to drain flow by<br />

adjusting the reject throttling valve. Open the valve to obtain a higher flow rate or<br />

close the valve to reduce the flow rate.<br />

Third, adjust the unit to make the correct amount of product and reject<br />

recirculation flows by adjusting the product and reject recirculation throttling<br />

valves. Further open the valve to obtain a higher flow rate or close the valve to<br />

reduce the flow rate.<br />

NOTE: Creating an equilibium may require several adjustments in that as you<br />

close the reject valves, the product flow increases and the reject flow<br />

decreases. As you open the pump discharge-throttling valve, the product<br />

and the reject flow increase. You may have to adjust the pump<br />

discharge-throttling valve to reestablish the operating pressure to obtain<br />

the correct product flow as established in the first step.<br />

<strong>USF</strong>ilter 3-3