USF RO ManualOMRX_6.pdf

USF RO ManualOMRX_6.pdf

USF RO ManualOMRX_6.pdf

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

RX Manual 04/04 Rev. 6 SYSTEM MAINTENANCE<br />

softened filtered tap water. Completely flush the system between<br />

applications of different cleaning solutions.<br />

3. Increase flow rates and decrease pressure.<br />

During cleaning, reject flow rates should be as high as possible without<br />

exceeding the maximum design flow of the system. The flow rate should<br />

be 8 - 12 gpm per vessel for the Med-<strong>RO</strong> series <strong>RO</strong> systems during<br />

cleaning. Pressure should be kept at a minimum during cleaning.<br />

Transmembrane pressure keeps foulants within or on the membrane<br />

surface during cleaning. The <strong>RO</strong> pump should be off during cleaning.<br />

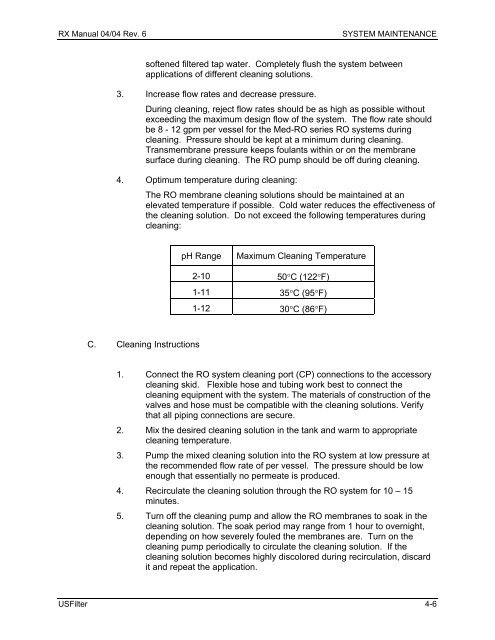

4. Optimum temperature during cleaning:<br />

The <strong>RO</strong> membrane cleaning solutions should be maintained at an<br />

elevated temperature if possible. Cold water reduces the effectiveness of<br />

the cleaning solution. Do not exceed the following temperatures during<br />

cleaning:<br />

C. Cleaning Instructions<br />

pH Range Maximum Cleaning Temperature<br />

2-10 50°C (122°F)<br />

1-11 35°C (95°F)<br />

1-12 30°C (86°F)<br />

1. Connect the <strong>RO</strong> system cleaning port (CP) connections to the accessory<br />

cleaning skid. Flexible hose and tubing work best to connect the<br />

cleaning equipment with the system. The materials of construction of the<br />

valves and hose must be compatible with the cleaning solutions. Verify<br />

that all piping connections are secure.<br />

2. Mix the desired cleaning solution in the tank and warm to appropriate<br />

cleaning temperature.<br />

3. Pump the mixed cleaning solution into the <strong>RO</strong> system at low pressure at<br />

the recommended flow rate of per vessel. The pressure should be low<br />

enough that essentially no permeate is produced.<br />

4. Recirculate the cleaning solution through the <strong>RO</strong> system for 10 – 15<br />

minutes.<br />

5. Turn off the cleaning pump and allow the <strong>RO</strong> membranes to soak in the<br />

cleaning solution. The soak period may range from 1 hour to overnight,<br />

depending on how severely fouled the membranes are. Turn on the<br />

cleaning pump periodically to circulate the cleaning solution. If the<br />

cleaning solution becomes highly discolored during recirculation, discard<br />

it and repeat the application.<br />

<strong>USF</strong>ilter 4-6