Download - Evonik Industries

Download - Evonik Industries

Download - Evonik Industries

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

24 HealtH & nutrition<br />

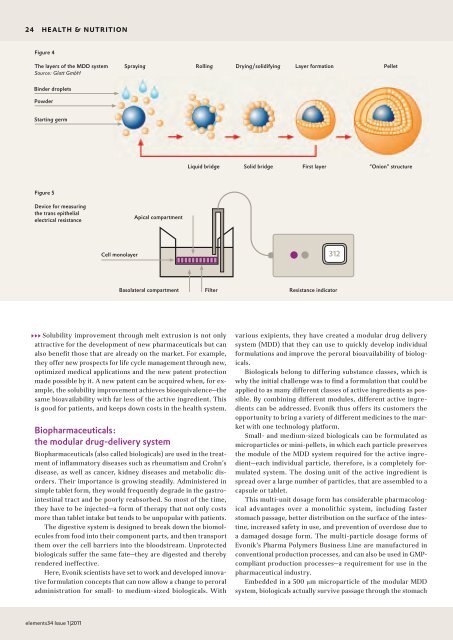

Figure 4<br />

The layers of the MDD system<br />

Source: Glatt GmbH<br />

Binder droplets<br />

Powder<br />

Starting germ<br />

Figure 5<br />

Device for measuring<br />

the trans epithelial<br />

electrical resistance<br />

333 Solubility improvement through melt extrusion is not only<br />

at tractive for the development of new pharmaceuticals but can<br />

also benefit those that are already on the market. For example,<br />

they offer new prospects for life cycle management through new,<br />

optimized medical applications and the new patent protection<br />

made possible by it. A new patent can be acquired when, for example,<br />

the solubility improvement achieves bioequivalence—the<br />

same bioavailability with far less of the active ingredient. This<br />

is good for patients, and keeps down costs in the health system.<br />

Biopharmaceuticals:<br />

the modular drug-delivery system<br />

Biopharmaceuticals (also called biologicals) are used in the treatment<br />

of inflammatory diseases such as rheumatism and Crohn’s<br />

disease, as well as cancer, kidney diseases and metabolic disorders.<br />

Their importance is growing steadily. Administered in<br />

simple tablet form, they would frequently degrade in the gastrointestinal<br />

tract and be poorly reabsorbed. So most of the time,<br />

they have to be injected—a form of therapy that not only costs<br />

more than tablet intake but tends to be unpopular with patients.<br />

The digestive system is designed to break down the biomolecules<br />

from food into their component parts, and then transport<br />

them over the cell barriers into the bloodstream. Unprotected<br />

biologicals suffer the same fate—they are digested and thereby<br />

rendered ineffective.<br />

Here, <strong>Evonik</strong> scientists have set to work and developed innovative<br />

formulation concepts that can now allow a change to peroral<br />

administration for small to mediumsized biologicals. With<br />

elements34 Issue 1|2011<br />

Cell monolayer<br />

Spraying Rolling Drying/solidifying Layer formation Pellet<br />

Apical compartment<br />

Basolateral compartment<br />

Liquid bridge Solid bridge First layer “Onion” structure<br />

Filter<br />

312<br />

Resistance indicator<br />

various exipients, they have created a modular drug delivery<br />

system (MDD) that they can use to quickly develop individual<br />

formulations and improve the peroral bioavailability of biologicals.<br />

Biologicals belong to differing substance classes, which is<br />

why the initial challenge was to find a formulation that could be<br />

applied to as many different classes of active ingredients as possible.<br />

By combining different modules, different active ingredients<br />

can be addressed. <strong>Evonik</strong> thus offers its customers the<br />

opportunity to bring a variety of different medicines to the market<br />

with one technology platform.<br />

Small and mediumsized biologicals can be formulated as<br />

microparticles or minipellets, in which each particle preserves<br />

the module of the MDD system required for the active ingredient—each<br />

individual particle, therefore, is a completely formulated<br />

system. The dosing unit of the active ingredient is<br />

spread over a large number of particles, that are assembled to a<br />

capsule or tablet.<br />

This multiunit dosage form has considerable pharmacological<br />

advantages over a monolithic system, including faster<br />

stomach passage, better distribution on the surface of the intestine,<br />

increased safety in use, and prevention of overdose due to<br />

a damaged dosage form. The multiparticle dosage forms of<br />

<strong>Evonik</strong>‘s Pharma Polymers Business Line are manufactured in<br />

conventional production processes, and can also be used in GMPcompliant<br />

production processes—a requirement for use in the<br />

pharmaceutical industry.<br />

Embedded in a 500 µm microparticle of the modular MDD<br />

system, biologicals actually survive passage through the stomach