final .cdr

final .cdr

final .cdr

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

From the technological point of view, an ideal buccal dosage<br />

form must have three properties; It must maintains its<br />

position in the mouth for a few hours, release the drug in<br />

controlled fashion and provide drug release in a<br />

unidirectional way towards mucosa.<br />

Atenolol (beta blocker), has been widely used in the<br />

management of hypertension. The drug is well absorbed<br />

from the gastrointestinal tract but its bioavailability is low<br />

4<br />

(54%) due to extensive first pass metabolism. Since the<br />

buccal route bypasses first-pass effect, the dose of atenolol<br />

could be reduced by 50%. The physicochemical properties<br />

of atenolol, its suitable half-life (6-7 h) and low molecular<br />

weight (266.34) makes it a suitable candidate for<br />

administration by buccal route. The effective permeation of<br />

the drug through bovine buccal mucosa has already been<br />

5<br />

reported.<br />

In the present study, an attempt was made to design<br />

efficacious and prolonged release mucoadhesive tablets of<br />

atenolol using various polymers to avoid first pass<br />

metabolism, to reduce dosing frequency and to improve<br />

patient compliance with improved bioavailability.<br />

MATERIALS AND METHODS<br />

Atenolol was gifted by Rajat Pharmachem Ltd,<br />

Ankaleshwar, Gujarat. Ethyl cellulose was gifted by (Arihant<br />

Trading co., Mumbai, India), hydroxypropyl<br />

methylcellulose 15 cps, 50 cps, (Colorcon Asia Pvt. Limited,<br />

Verna, India) and carbopol 934p were gifted by ( ShinEtsu<br />

Chemical Co. Ltd Japan). All other materials were of<br />

analytical or pharmacopoeial grade and used as received.<br />

6-7<br />

Preparation of the buccal tablets<br />

Preparation: Direct compression method has been<br />

employed to prepare buccal tablets of atenolol using HPMC<br />

15cps, HPMC 50cps and Carbopol 934p as polymers.<br />

S B Shirsand et al Design and Evaluation of Atenolol Bilayer Buccal Tablets<br />

Procedure: All the ingredients including drug, polymer<br />

and excipients were weighed accurately according to the<br />

batch formula (Table 1). The drug is thoroughly mixed with<br />

mannitol on a butter paper with the help of a stainless steel<br />

spatula. Then all the ingredients except lubricant were<br />

mixed in the order of ascending weights and blended for 10<br />

min in an inflated polyethylene pouch. After uniform mixing<br />

of ingredients, lubricant was added and again mixed for 2<br />

min. The prepared blend (100 mg) of each formulation was<br />

pre-compressed, on a 10-station roatory tablet punching<br />

machine (Clit, Ahmedabad) at a pressure of 0.5 ton and<br />

turret speed of 2 rpm to form single layered flat-faced tablet<br />

of 9 mm diameter. Then, 50 mg of ethyl cellulose powder<br />

was added and <strong>final</strong> compression was done at a pressure of<br />

3.5 tons and turret speed of 2 rpm to get bilayer tablet.<br />

Evaluation of buccal tablets<br />

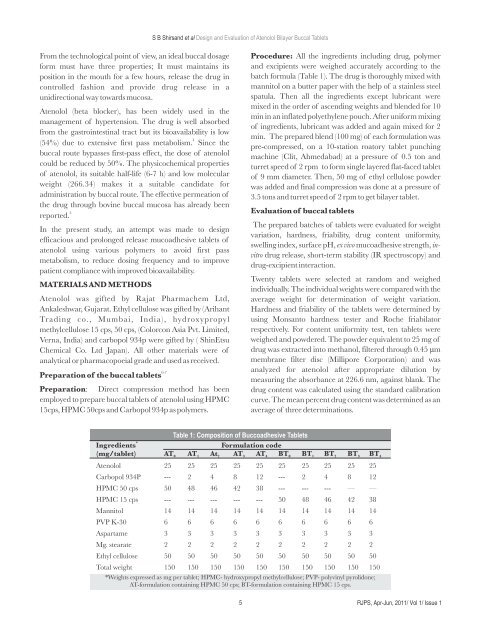

Table 1: Composition of Buccoadhesive Tablets<br />

*<br />

Ingredients Formulation code<br />

The prepared batches of tablets were evaluated for weight<br />

variation, hardness, friability, drug content uniformity,<br />

swelling index, surface pH, ex vivo mucoadhesive strength, invitro<br />

drug release, short-term stability (IR spectroscopy) and<br />

drug-excipient interaction.<br />

Twenty tablets were selected at random and weighed<br />

individually. The individual weights were compared with the<br />

average weight for determination of weight variation.<br />

Hardness and friability of the tablets were determined by<br />

using Monsanto hardness tester and Roche friabilator<br />

respectively. For content uniformity test, ten tablets were<br />

weighed and powdered. The powder equivalent to 25 mg of<br />

drug was extracted into methanol, filtered through 0.45 μm<br />

membrane filter disc (Millipore Corporation) and was<br />

analyzed for atenolol after appropriate dilution by<br />

measuring the absorbance at 226.6 nm, against blank. The<br />

drug content was calculated using the standard calibration<br />

curve. The mean percent drug content was determined as an<br />

average of three determinations.<br />

(mg/tablet) AT AT At AT AT BT BT BT BT BT<br />

0 1<br />

2 3 4 0 1 2 3 4<br />

Atenolol 25 25 25 25 25 25 25 25 25 25<br />

Carbopol 934P --- 2 4 8 12 --- 2 4 8 12<br />

HPMC 50 cps 50 48 46 42 38 --- --- --- — —<br />

HPMC 15 cps --- --- --- --- --- 50 48 46 42 38<br />

Mannitol 14 14 14 14 14 14 14 14 14 14<br />

PVP K-30 6 6 6 6 6 6 6 6 6 6<br />

Aspartame 3 3 3 3 3 3 3 3 3 3<br />

Mg. stearate 2 2 2 2 2 2 2 2 2 2<br />

Ethyl cellulose 50 50 50 50 50 50 50 50 50 50<br />

Total weight 150 150 150 150 150 150 150 150 150 150<br />

*Weights expressed as mg per tablet; HPMC- hydroxypropyl methylcellulose; PVP- polyvinyl pyrolidone;<br />

AT-formulation containing HPMC 50 cps; BT-formulation containing HPMC 15 cps.<br />

5<br />

RJPS, Apr-Jun, 2011/ Vol 1/ Issue 1