weld 1100 - shielded metal arc welding - College of Eastern Utah

weld 1100 - shielded metal arc welding - College of Eastern Utah

weld 1100 - shielded metal arc welding - College of Eastern Utah

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

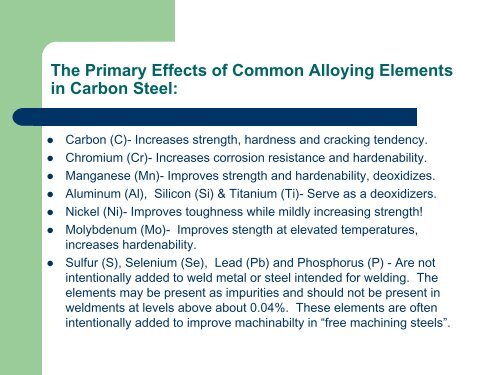

The Primary Effects <strong>of</strong> Common Alloying Elements<br />

in Carbon Steel:<br />

Carbon (C)- Increases strength, hardness and cracking tendency.<br />

Chromium (Cr)- Increases corrosion resistance and hardenability.<br />

Manganese (Mn)- Improves strength and hardenability, deoxidizes.<br />

Aluminum (Al), Silicon (Si) & Titanium (Ti)- Serve as a deoxidizers.<br />

Nickel (Ni)- Improves toughness while mildly increasing strength!<br />

Molybdenum (Mo)- Improves stength at elevated temperatures,<br />

increases hardenability.<br />

Sulfur (S), Selenium (Se), Lead (Pb) and Phosphorus (P) - Are not<br />

intentionally added to <strong>weld</strong> <strong>metal</strong> or steel intended for <strong>weld</strong>ing. The<br />

elements may be present as impurities and should not be present in<br />

<strong>weld</strong>ments at levels above about 0.04%. These elements are <strong>of</strong>ten<br />

intentionally added to improve machinabilty in “free machining steels”.