weld 1100 - shielded metal arc welding - College of Eastern Utah

weld 1100 - shielded metal arc welding - College of Eastern Utah

weld 1100 - shielded metal arc welding - College of Eastern Utah

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

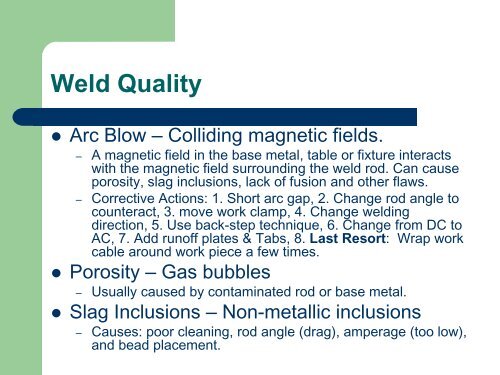

Weld Quality<br />

Arc Blow – Colliding magnetic fields.<br />

– A magnetic field in the base <strong>metal</strong>, table or fixture interacts<br />

with the magnetic field surrounding the <strong>weld</strong> rod. Can cause<br />

porosity, slag inclusions, lack <strong>of</strong> fusion and other flaws.<br />

– Corrective Actions: 1. Short <strong>arc</strong> gap, 2. Change rod angle to<br />

counteract, 3. move work clamp, 4. Change <strong>weld</strong>ing<br />

direction, 5. Use back-step technique, 6. Change from DC to<br />

AC, 7. Add run<strong>of</strong>f plates & Tabs, 8. Last Resort: Wrap work<br />

cable around work piece a few times.<br />

Porosity – Gas bubbles<br />

– Usually caused by contaminated rod or base <strong>metal</strong>.<br />

Slag Inclusions – Non-<strong>metal</strong>lic inclusions<br />

– Causes: poor cleaning, rod angle (drag), amperage (too low),<br />

and bead placement.