weld 1100 - shielded metal arc welding - College of Eastern Utah

weld 1100 - shielded metal arc welding - College of Eastern Utah

weld 1100 - shielded metal arc welding - College of Eastern Utah

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

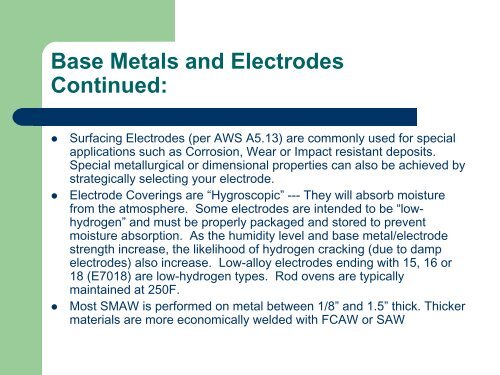

Base Metals and Electrodes<br />

Continued:<br />

Surfacing Electrodes (per AWS A5.13) are commonly used for special<br />

applications such as Corrosion, Wear or Impact resistant deposits.<br />

Special <strong>metal</strong>lurgical or dimensional properties can also be achieved by<br />

strategically selecting your electrode.<br />

Electrode Coverings are “Hygroscopic” --- They will absorb moisture<br />

from the atmosphere. Some electrodes are intended to be “lowhydrogen”<br />

and must be properly packaged and stored to prevent<br />

moisture absorption. As the humidity level and base <strong>metal</strong>/electrode<br />

strength increase, the likelihood <strong>of</strong> hydrogen cracking (due to damp<br />

electrodes) also increase. Low-alloy electrodes ending with 15, 16 or<br />

18 (E7018) are low-hydrogen types. Rod ovens are typically<br />

maintained at 250F.<br />

Most SMAW is performed on <strong>metal</strong> between 1/8” and 1.5” thick. Thicker<br />

materials are more economically <strong>weld</strong>ed with FCAW or SAW