“Influence of Si, Sb and Sr Additions on the Microstructure ...

“Influence of Si, Sb and Sr Additions on the Microstructure ...

“Influence of Si, Sb and Sr Additions on the Microstructure ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

_ pg Chapter 4: Results <str<strong>on</strong>g>and</str<strong>on</strong>g> Discussi<strong>on</strong><br />

=<br />

ac WISSI<br />

M910<br />

$1<br />

M ____ WI ,___ ;_ -C_;..s<br />

_<br />

an l‘ — w ' Z: ' \ — _599‘C fi ‘ Tj 1 !1 *<br />

i, K ii ' ji<br />

$@p ' ~——~i~* "Ff e T “ ‘ i 1<br />

aw .é gv E 5-(PC<br />

mm 2; v ii ~426'c i * __+._ T i. L T _..--._.....___ T‘ _<br />

I l<br />

max 1 _.,(;._ l ls- >,o;;jTi; 1'<br />

aw __ _,_,_ ___ .._. .. . . <br />

APKSI<br />

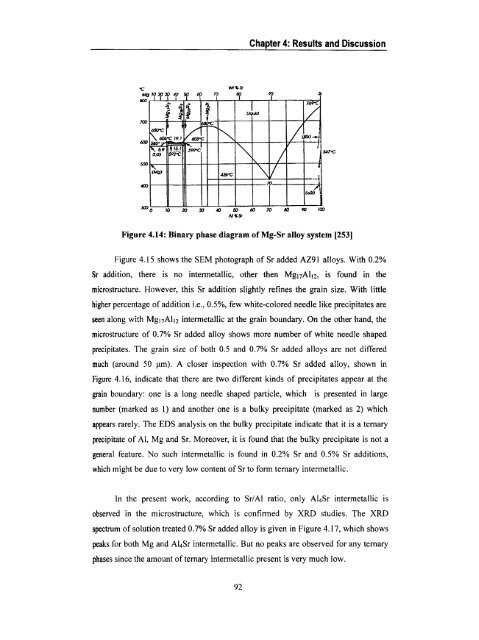

Figure 4.14: Binary phase diagram <str<strong>on</strong>g>of</str<strong>on</strong>g> Mg-<str<strong>on</strong>g>Sr</str<strong>on</strong>g> alloy system [253]<br />

Figure 4.15 shows <strong>the</strong> SEM photograph <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>Sr</str<strong>on</strong>g> added AZ91 alloys. With 0.2%<br />

<str<strong>on</strong>g>Sr</str<strong>on</strong>g> additi<strong>on</strong>, <strong>the</strong>re is no intermetallic, o<strong>the</strong>r <strong>the</strong>n Mg11Al|2, is found in <strong>the</strong><br />

microstructure. However, this <str<strong>on</strong>g>Sr</str<strong>on</strong>g> additi<strong>on</strong> slightly refines <strong>the</strong> grain size. With little<br />

higher percentage <str<strong>on</strong>g>of</str<strong>on</strong>g> additi<strong>on</strong> i.e., 0.5%, few white-colored needle like precipitates are<br />

seen al<strong>on</strong>g with Mg17Al,2 intermetallic at <strong>the</strong> grain boundary. On <strong>the</strong> o<strong>the</strong>r h<str<strong>on</strong>g>and</str<strong>on</strong>g>, <strong>the</strong><br />

microstructure <str<strong>on</strong>g>of</str<strong>on</strong>g> 0.7% <str<strong>on</strong>g>Sr</str<strong>on</strong>g> added alloy shows more number <str<strong>on</strong>g>of</str<strong>on</strong>g> white needle shaped<br />

precipitates. The grain size <str<strong>on</strong>g>of</str<strong>on</strong>g> both 0.5 <str<strong>on</strong>g>and</str<strong>on</strong>g> 0.7% <str<strong>on</strong>g>Sr</str<strong>on</strong>g> added alloys are not differed<br />

much (around 50 um). A closer inspecti<strong>on</strong> with 0.7% <str<strong>on</strong>g>Sr</str<strong>on</strong>g> added alloy, shown in<br />

Figure 4.16, indicate that <strong>the</strong>re are two different kinds <str<strong>on</strong>g>of</str<strong>on</strong>g> precipitates appear at <strong>the</strong><br />

grain boundary: <strong>on</strong>e is a l<strong>on</strong>g needle shaped particle, which is presented in large<br />

number (marked as 1) <str<strong>on</strong>g>and</str<strong>on</strong>g> ano<strong>the</strong>r <strong>on</strong>e is a bulky precipitate (marked as 2) which<br />

appears rarely. The EDS analysis <strong>on</strong> <strong>the</strong> bulky precipitate indicate that it is a temary<br />

precipitate <str<strong>on</strong>g>of</str<strong>on</strong>g> Al, Mg <str<strong>on</strong>g>and</str<strong>on</strong>g> <str<strong>on</strong>g>Sr</str<strong>on</strong>g>. Moreover, it is found that <strong>the</strong> bulky precipitate is not a<br />

general feature. No such intermetallic is found in 0.2% <str<strong>on</strong>g>Sr</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g> 0.5% <str<strong>on</strong>g>Sr</str<strong>on</strong>g> additi<strong>on</strong>s,<br />

which might be due to very low c<strong>on</strong>tent <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>Sr</str<strong>on</strong>g> to fomi temary intermetallic.<br />

In <strong>the</strong> present work, according to <str<strong>on</strong>g>Sr</str<strong>on</strong>g>/Al ratio, <strong>on</strong>ly Al4<str<strong>on</strong>g>Sr</str<strong>on</strong>g> intermetallic is<br />

observed in <strong>the</strong> microstructure, which is c<strong>on</strong>firmed by XRD studies. The XRD<br />

spectrum <str<strong>on</strong>g>of</str<strong>on</strong>g> soluti<strong>on</strong> treated 0.7% <str<strong>on</strong>g>Sr</str<strong>on</strong>g> added alloy is given in Figure 4.17, which shows<br />

peaks for both Mg <str<strong>on</strong>g>and</str<strong>on</strong>g> Al4<str<strong>on</strong>g>Sr</str<strong>on</strong>g> intemetallic. But no peaks are observed for any temary<br />

phases since <strong>the</strong> amount <str<strong>on</strong>g>of</str<strong>on</strong>g> ternary intermetallic present is very much low.<br />

92