“Influence of Si, Sb and Sr Additions on the Microstructure ...

“Influence of Si, Sb and Sr Additions on the Microstructure ...

“Influence of Si, Sb and Sr Additions on the Microstructure ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

W g_ Chapter 4: Results <str<strong>on</strong>g>and</str<strong>on</strong>g> Discussi<strong>on</strong><br />

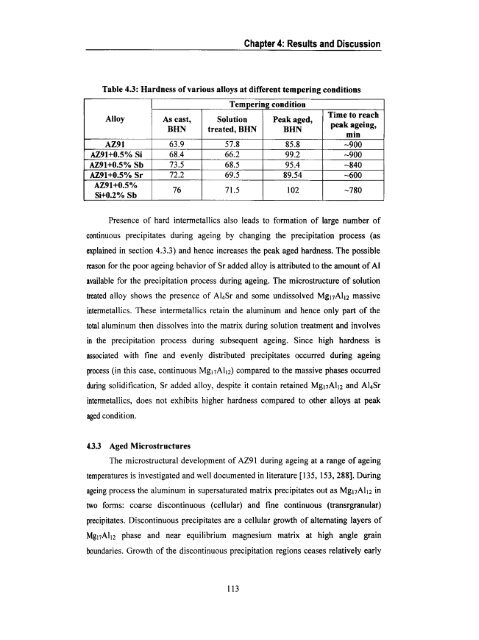

Table 4.3: Hardness <str<strong>on</strong>g>of</str<strong>on</strong>g> various alloys at different tempering c<strong>on</strong>diti<strong>on</strong>s<br />

.T¢mp@ring c<strong>on</strong>diti<strong>on</strong> e<br />

up g g H _ 8 llllll<br />

\ Alloy A As cast, Soluti<strong>on</strong> Peak aged, Time to reach<br />

BHN treated, BHN BHN peak “,g°i“g’<br />

up AZ91 63.9 5_7.8 85.8 ~900<br />

‘_gAz91+0.s% <str<strong>on</strong>g>Si</str<strong>on</strong>g> 68.1‘ 66.2 99.2 ~900<br />

Az91+o.5% <str<strong>on</strong>g>Sb</str<strong>on</strong>g> 273.5 i“T6s.s 95.4T ~s4o<br />

T AZ91+0.5% <str<strong>on</strong>g>Sr</str<strong>on</strong>g> 72.2 69.5" 89.54 ~600<br />

it AZ9l+0.5%<br />

<str<strong>on</strong>g>Si</str<strong>on</strong>g>+0.2%<str<strong>on</strong>g>Sb</str<strong>on</strong>g> 76 W 102 K ~7so<br />

Presence <str<strong>on</strong>g>of</str<strong>on</strong>g> hard intermetallies also leads to formati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> large number <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

c<strong>on</strong>tinuous precipitates during ageing by changing <strong>the</strong> precipitati<strong>on</strong> process (as<br />

explained in secti<strong>on</strong> 4.3.3) <str<strong>on</strong>g>and</str<strong>on</strong>g> hence increases <strong>the</strong> peak aged hardness. The possible<br />

reas<strong>on</strong> for <strong>the</strong> poor ageing behavior <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>Sr</str<strong>on</strong>g> added alloy is attributed to <strong>the</strong> amount <str<strong>on</strong>g>of</str<strong>on</strong>g> Al<br />

available for <strong>the</strong> precipitati<strong>on</strong> process during ageing. The microstmcture <str<strong>on</strong>g>of</str<strong>on</strong>g> soluti<strong>on</strong><br />

treated alloy shows <strong>the</strong> presence <str<strong>on</strong>g>of</str<strong>on</strong>g> Al4<str<strong>on</strong>g>Sr</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g> some undissolved Mg11Al|2 massive<br />

intermetallics. These intermetallics retain <strong>the</strong> aluminum <str<strong>on</strong>g>and</str<strong>on</strong>g> hence <strong>on</strong>ly part <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong><br />

total aluminum <strong>the</strong>n dissolves into <strong>the</strong> matrix during soluti<strong>on</strong> treatment <str<strong>on</strong>g>and</str<strong>on</strong>g> involves<br />

in <strong>the</strong> precipitati<strong>on</strong> process during subsequent ageing. <str<strong>on</strong>g>Si</str<strong>on</strong>g>nce high hardness is<br />

associated with fine <str<strong>on</strong>g>and</str<strong>on</strong>g> evenly distributed precipitates occurred during ageing<br />

process (in this case, c<strong>on</strong>tinuous Mg;-;Al;2) compared to <strong>the</strong> massive phases occurred<br />

during solidificati<strong>on</strong>, <str<strong>on</strong>g>Sr</str<strong>on</strong>g> added alloy, despite it c<strong>on</strong>tain retained Mg]-,Al1; <str<strong>on</strong>g>and</str<strong>on</strong>g> Al4<str<strong>on</strong>g>Sr</str<strong>on</strong>g><br />

intermetallics, does not exhibits higher hardness compared to o<strong>the</strong>r alloys at peak<br />

aged c<strong>on</strong>diti<strong>on</strong>.<br />

4.3.3 Aged <strong>Microstructure</strong>s<br />

The microstructural development <str<strong>on</strong>g>of</str<strong>on</strong>g> AZ9l during ageing at a range <str<strong>on</strong>g>of</str<strong>on</strong>g> ageing<br />

temperatures is investigated <str<strong>on</strong>g>and</str<strong>on</strong>g> well documented in literature [l35, 153, 288]. During<br />

ageing process <strong>the</strong> aluminum in supersaturated matrix precipitates out as Mg17Al1;; in<br />

two forms: coarse disc<strong>on</strong>tinuous (cellular) <str<strong>on</strong>g>and</str<strong>on</strong>g> fine c<strong>on</strong>tinuous (transrgranular)<br />

precipitates. Disc<strong>on</strong>tinuous precipitates are a cellular growth <str<strong>on</strong>g>of</str<strong>on</strong>g> altemating layers <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

Mg17Al12 phase <str<strong>on</strong>g>and</str<strong>on</strong>g> near equilibrium magnesium matrix at high angle grain<br />

boundaries. Growth <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> disc<strong>on</strong>tinuous precipitati<strong>on</strong> regi<strong>on</strong>s ceases relatively early<br />

113