MDI Emissions Reporting Guidelines for the ... - Polyurethanes

MDI Emissions Reporting Guidelines for the ... - Polyurethanes

MDI Emissions Reporting Guidelines for the ... - Polyurethanes

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

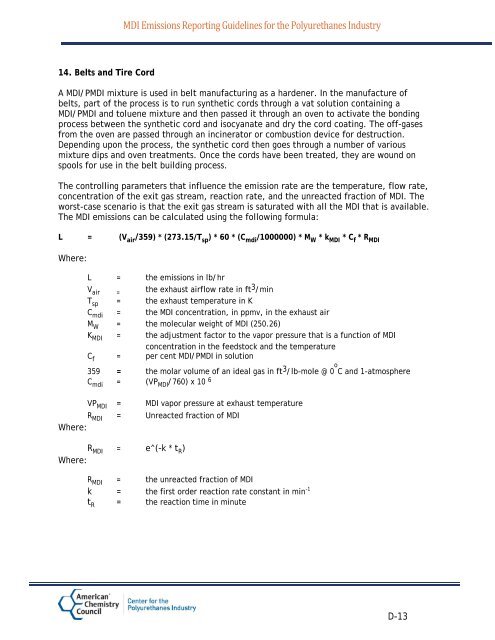

14. Belts and Tire Cord<br />

<strong>MDI</strong> <strong>Emissions</strong> <strong>Reporting</strong> <strong>Guidelines</strong> <strong>for</strong> <strong>the</strong> <strong>Polyurethanes</strong> Industry<br />

A <strong>MDI</strong>/P<strong>MDI</strong> mixture is used in belt manufacturing as a hardener. In <strong>the</strong> manufacture of<br />

belts, part of <strong>the</strong> process is to run syn<strong>the</strong>tic cords through a vat solution containing a<br />

<strong>MDI</strong>/P<strong>MDI</strong> and toluene mixture and <strong>the</strong>n passed it through an oven to activate <strong>the</strong> bonding<br />

process between <strong>the</strong> syn<strong>the</strong>tic cord and isocyanate and dry <strong>the</strong> cord coating. The off-gases<br />

from <strong>the</strong> oven are passed through an incinerator or combustion device <strong>for</strong> destruction.<br />

Depending upon <strong>the</strong> process, <strong>the</strong> syn<strong>the</strong>tic cord <strong>the</strong>n goes through a number of various<br />

mixture dips and oven treatments. Once <strong>the</strong> cords have been treated, <strong>the</strong>y are wound on<br />

spools <strong>for</strong> use in <strong>the</strong> belt building process.<br />

The controlling parameters that influence <strong>the</strong> emission rate are <strong>the</strong> temperature, flow rate,<br />

concentration of <strong>the</strong> exit gas stream, reaction rate, and <strong>the</strong> unreacted fraction of <strong>MDI</strong>. The<br />

worst-case scenario is that <strong>the</strong> exit gas stream is saturated with all <strong>the</strong> <strong>MDI</strong> that is available.<br />

The <strong>MDI</strong> emissions can be calculated using <strong>the</strong> following <strong>for</strong>mula:<br />

L = (V air /359) * (273.15/T sp ) * 60 * (C mdi /1000000) * M W * k <strong>MDI</strong> * C f * R <strong>MDI</strong><br />

Where:<br />

L = <strong>the</strong> emissions in lb/hr<br />

Vair = <strong>the</strong> exhaust airflow rate in ft3 /min<br />

Tsp = <strong>the</strong> exhaust temperature in K<br />

Cmdi = <strong>the</strong> <strong>MDI</strong> concentration, in ppmv, in <strong>the</strong> exhaust air<br />

MW = <strong>the</strong> molecular weight of <strong>MDI</strong> (250.26)<br />

K<strong>MDI</strong> = <strong>the</strong> adjustment factor to <strong>the</strong> vapor pressure that is a function of <strong>MDI</strong><br />

concentration in <strong>the</strong> feedstock and <strong>the</strong> temperature<br />

Cf = per cent <strong>MDI</strong>/P<strong>MDI</strong> in solution<br />

359 = <strong>the</strong> molar volume of an ideal gas in ft3 /lb-mole @ 0 o<br />

C and 1-atmosphere<br />

Cmdi = (VP<strong>MDI</strong> /760) x 10 6<br />

VP <strong>MDI</strong> = <strong>MDI</strong> vapor pressure at exhaust temperature<br />

R <strong>MDI</strong> = Unreacted fraction of <strong>MDI</strong><br />

Where:<br />

R <strong>MDI</strong> = e^(-k * t R )<br />

Where:<br />

R <strong>MDI</strong> = <strong>the</strong> unreacted fraction of <strong>MDI</strong><br />

k = <strong>the</strong> first order reaction rate constant in min -1<br />

t R = <strong>the</strong> reaction time in minute<br />

D-13