MDI Emissions Reporting Guidelines for the ... - Polyurethanes

MDI Emissions Reporting Guidelines for the ... - Polyurethanes

MDI Emissions Reporting Guidelines for the ... - Polyurethanes

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

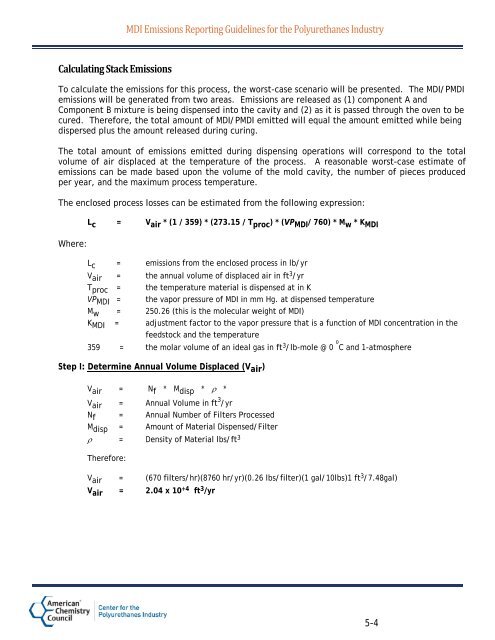

Calculating Stack <strong>Emissions</strong><br />

<strong>MDI</strong> <strong>Emissions</strong> <strong>Reporting</strong> <strong>Guidelines</strong> <strong>for</strong> <strong>the</strong> <strong>Polyurethanes</strong> Industry<br />

To calculate <strong>the</strong> emissions <strong>for</strong> this process, <strong>the</strong> worst-case scenario will be presented. The <strong>MDI</strong>/P<strong>MDI</strong><br />

emissions will be generated from two areas. <strong>Emissions</strong> are released as (1) component A and<br />

Component B mixture is being dispensed into <strong>the</strong> cavity and (2) as it is passed through <strong>the</strong> oven to be<br />

cured. There<strong>for</strong>e, <strong>the</strong> total amount of <strong>MDI</strong>/P<strong>MDI</strong> emitted will equal <strong>the</strong> amount emitted while being<br />

dispersed plus <strong>the</strong> amount released during curing.<br />

The total amount of emissions emitted during dispensing operations will correspond to <strong>the</strong> total<br />

volume of air displaced at <strong>the</strong> temperature of <strong>the</strong> process. A reasonable worst-case estimate of<br />

emissions can be made based upon <strong>the</strong> volume of <strong>the</strong> mold cavity, <strong>the</strong> number of pieces produced<br />

per year, and <strong>the</strong> maximum process temperature.<br />

The enclosed process losses can be estimated from <strong>the</strong> following expression:<br />

Where:<br />

L c = V air * (1 / 359) * (273.15 / T proc ) * (VP <strong>MDI</strong> / 760) * M w * K <strong>MDI</strong><br />

Lc = emissions from <strong>the</strong> enclosed process in lb/yr<br />

Vair = <strong>the</strong> annual volume of displaced air in ft3 /yr<br />

Tproc = <strong>the</strong> temperature material is dispensed at in K<br />

VP<strong>MDI</strong> = <strong>the</strong> vapor pressure of <strong>MDI</strong> in mm Hg. at dispensed temperature<br />

Mw = 250.26 (this is <strong>the</strong> molecular weight of <strong>MDI</strong>)<br />

K<strong>MDI</strong> = adjustment factor to <strong>the</strong> vapor pressure that is a function of <strong>MDI</strong> concentration in <strong>the</strong><br />

feedstock and <strong>the</strong> temperature<br />

359 = <strong>the</strong> molar volume of an ideal gas in ft3 /lb-mole @ 0 o<br />

C and 1-atmosphere<br />

Step I: Determine Annual Volume Displaced (V air )<br />

Vair = Nf * Mdisp * *<br />

Vair = Annual Volume in ft 3 Nf =<br />

/yr<br />

Annual Number of Filters Processed<br />

Mdisp = Amount of Material Dispensed/Filter<br />

= Density of Material lbs/ft 3<br />

There<strong>for</strong>e:<br />

Vair = (670 filters/hr)(8760 hr/yr)(0.26 lbs/filter)(1 gal/10lbs)1 ft3 /7.48gal)<br />

Vair = 2.04 x 10 +4 ft3 /yr<br />

5-4