MDI Emissions Reporting Guidelines for the ... - Polyurethanes

MDI Emissions Reporting Guidelines for the ... - Polyurethanes

MDI Emissions Reporting Guidelines for the ... - Polyurethanes

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>MDI</strong> <strong>Emissions</strong> <strong>Reporting</strong> <strong>Guidelines</strong> <strong>for</strong> <strong>the</strong> <strong>Polyurethanes</strong> Industry<br />

hour, and production operates 16 hours per day 250 days a year.<br />

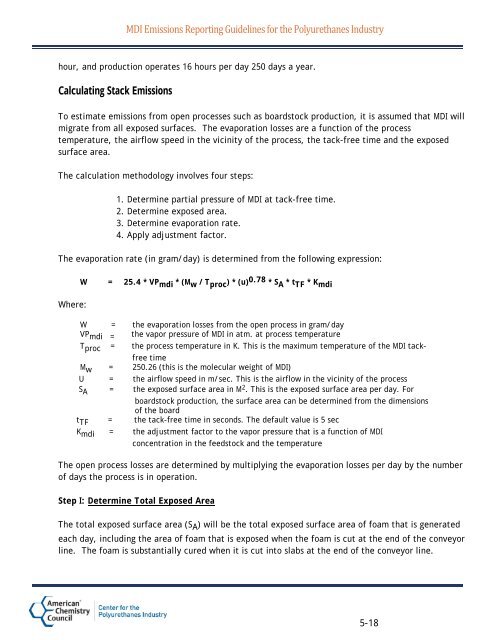

Calculating Stack <strong>Emissions</strong><br />

To estimate emissions from open processes such as boardstock production, it is assumed that <strong>MDI</strong> will<br />

migrate from all exposed surfaces. The evaporation losses are a function of <strong>the</strong> process<br />

temperature, <strong>the</strong> airflow speed in <strong>the</strong> vicinity of <strong>the</strong> process, <strong>the</strong> tack-free time and <strong>the</strong> exposed<br />

surface area.<br />

The calculation methodology involves four steps:<br />

1. Determine partial pressure of <strong>MDI</strong> at tack-free time.<br />

2. Determine exposed area.<br />

3. Determine evaporation rate.<br />

4. Apply adjustment factor.<br />

The evaporation rate (in gram/day) is determined from <strong>the</strong> following expression:<br />

Where:<br />

W = 25.4 * VP mdi * (M w / T proc ) * (u) 0.78 * S A * t TF * K mdi<br />

W = <strong>the</strong> evaporation losses from <strong>the</strong> open process in gram/day<br />

VPmdi = <strong>the</strong> vapor pressure of <strong>MDI</strong> in atm. at process temperature<br />

Tproc = <strong>the</strong> process temperature in K. This is <strong>the</strong> maximum temperature of <strong>the</strong> <strong>MDI</strong> tackfree<br />

time<br />

Mw = 250.26 (this is <strong>the</strong> molecular weight of <strong>MDI</strong>)<br />

U = <strong>the</strong> airflow speed in m/sec. This is <strong>the</strong> airflow in <strong>the</strong> vicinity of <strong>the</strong> process<br />

SA = <strong>the</strong> exposed surface area in M2 . This is <strong>the</strong> exposed surface area per day. For<br />

boardstock production, <strong>the</strong> surface area can be determined from <strong>the</strong> dimensions<br />

of <strong>the</strong> board<br />

tTF = <strong>the</strong> tack-free time in seconds. The default value is 5 sec<br />

Kmdi = <strong>the</strong> adjustment factor to <strong>the</strong> vapor pressure that is a function of <strong>MDI</strong><br />

concentration in <strong>the</strong> feedstock and <strong>the</strong> temperature<br />

The open process losses are determined by multiplying <strong>the</strong> evaporation losses per day by <strong>the</strong> number<br />

of days <strong>the</strong> process is in operation.<br />

Step I: Determine Total Exposed Area<br />

The total exposed surface area (SA ) will be <strong>the</strong> total exposed surface area of foam that is generated<br />

each day, including <strong>the</strong> area of foam that is exposed when <strong>the</strong> foam is cut at <strong>the</strong> end of <strong>the</strong> conveyor<br />

line. The foam is substantially cured when it is cut into slabs at <strong>the</strong> end of <strong>the</strong> conveyor line.<br />

5-18