MDI Emissions Reporting Guidelines for the ... - Polyurethanes

MDI Emissions Reporting Guidelines for the ... - Polyurethanes

MDI Emissions Reporting Guidelines for the ... - Polyurethanes

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

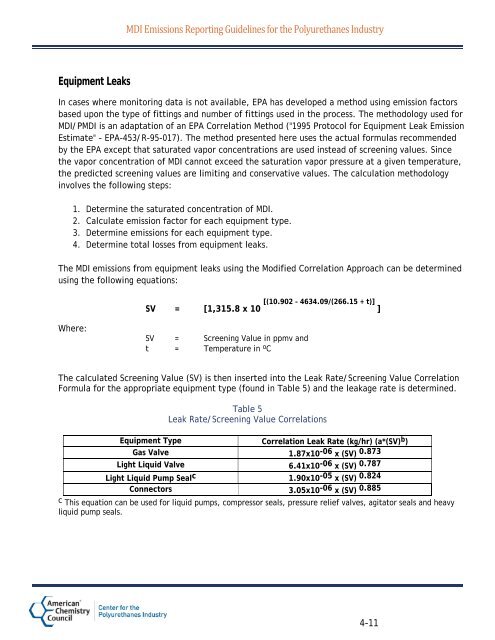

Equipment Leaks<br />

<strong>MDI</strong> <strong>Emissions</strong> <strong>Reporting</strong> <strong>Guidelines</strong> <strong>for</strong> <strong>the</strong> <strong>Polyurethanes</strong> Industry<br />

In cases where monitoring data is not available, EPA has developed a method using emission factors<br />

based upon <strong>the</strong> type of fittings and number of fittings used in <strong>the</strong> process. The methodology used <strong>for</strong><br />

<strong>MDI</strong>/P<strong>MDI</strong> is an adaptation of an EPA Correlation Method ("1995 Protocol <strong>for</strong> Equipment Leak Emission<br />

Estimate" - EPA-453/R-95-017). The method presented here uses <strong>the</strong> actual <strong>for</strong>mulas recommended<br />

by <strong>the</strong> EPA except that saturated vapor concentrations are used instead of screening values. Since<br />

<strong>the</strong> vapor concentration of <strong>MDI</strong> cannot exceed <strong>the</strong> saturation vapor pressure at a given temperature,<br />

<strong>the</strong> predicted screening values are limiting and conservative values. The calculation methodology<br />

involves <strong>the</strong> following steps:<br />

1. Determine <strong>the</strong> saturated concentration of <strong>MDI</strong>.<br />

2. Calculate emission factor <strong>for</strong> each equipment type.<br />

3. Determine emissions <strong>for</strong> each equipment type.<br />

4. Determine total losses from equipment leaks.<br />

The <strong>MDI</strong> emissions from equipment leaks using <strong>the</strong> Modified Correlation Approach can be determined<br />

using <strong>the</strong> following equations:<br />

Where:<br />

[(10.902 – 4634.09/(266.15 + t)]<br />

SV = [1,315.8 x 10 ]<br />

SV = Screening Value in ppmv and<br />

t = Temperature in o C<br />

The calculated Screening Value (SV) is <strong>the</strong>n inserted into <strong>the</strong> Leak Rate/Screening Value Correlation<br />

Formula <strong>for</strong> <strong>the</strong> appropriate equipment type (found in Table 5) and <strong>the</strong> leakage rate is determined.<br />

Table 5<br />

Leak Rate/Screening Value Correlations<br />

Equipment Type Correlation Leak Rate (kg/hr) (a*(SV) b )<br />

Gas Valve 1.87x10 -06 x (SV) 0.873<br />

Light Liquid Valve 6.41x10-06 x (SV) 0.787<br />

Light Liquid Pump Sealc 1.90x10-05 x (SV) 0.824<br />

Connectors 3.05x10-06 x (SV) 0.885<br />

c This equation can be used <strong>for</strong> liquid pumps, compressor seals, pressure relief valves, agitator seals and heavy<br />

liquid pump seals.<br />

4-11