MDI Emissions Reporting Guidelines for the ... - Polyurethanes

MDI Emissions Reporting Guidelines for the ... - Polyurethanes

MDI Emissions Reporting Guidelines for the ... - Polyurethanes

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

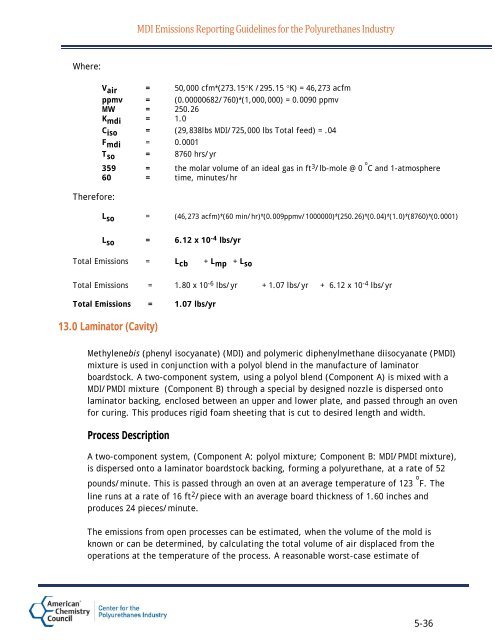

Where:<br />

There<strong>for</strong>e:<br />

<strong>MDI</strong> <strong>Emissions</strong> <strong>Reporting</strong> <strong>Guidelines</strong> <strong>for</strong> <strong>the</strong> <strong>Polyurethanes</strong> Industry<br />

Vair = 50,000 cfm*(273.15K /295.15 K) = 46,273 acfm<br />

ppmv = (0.00000682/760)*(1,000,000) = 0.0090 ppmv<br />

MW = 250.26<br />

Kmdi = 1.0<br />

Ciso = (29,838lbs <strong>MDI</strong>/725,000 lbs Total feed) = .04<br />

Fmdi = 0.0001<br />

Tso = 8760 hrs/yr<br />

359 = <strong>the</strong> molar volume of an ideal gas in ft3 /lb-mole @ 0 o<br />

C and 1-atmosphere<br />

60 = time, minutes/hr<br />

L so = (46,273 acfm)*(60 min/hr)*(0.009ppmv/1000000)*(250.26)*(0.04)*(1.0)*(8760)*(0.0001)<br />

L so = 6.12 x 10 -4 lbs/yr<br />

Total <strong>Emissions</strong> = L cb + L mp + L so<br />

Total <strong>Emissions</strong> = 1.80 x 10 -6 lbs/yr + 1.07 lbs/yr + 6.12 x 10 -4 lbs/yr<br />

Total <strong>Emissions</strong> = 1.07 lbs/yr<br />

13.0 Laminator (Cavity)<br />

Methylenebis (phenyl isocyanate) (<strong>MDI</strong>) and polymeric diphenylmethane diisocyanate (P<strong>MDI</strong>)<br />

mixture is used in conjunction with a polyol blend in <strong>the</strong> manufacture of laminator<br />

boardstock. A two-component system, using a polyol blend (Component A) is mixed with a<br />

<strong>MDI</strong>/P<strong>MDI</strong> mixture (Component B) through a special by designed nozzle is dispersed onto<br />

laminator backing, enclosed between an upper and lower plate, and passed through an oven<br />

<strong>for</strong> curing. This produces rigid foam sheeting that is cut to desired length and width.<br />

Process Description<br />

A two-component system, (Component A: polyol mixture; Component B: <strong>MDI</strong>/P<strong>MDI</strong> mixture),<br />

is dispersed onto a laminator boardstock backing, <strong>for</strong>ming a polyurethane, at a rate of 52<br />

pounds/minute. This is passed through an oven at an average temperature of 123 o<br />

F. The<br />

line runs at a rate of 16 ft2 /piece with an average board thickness of 1.60 inches and<br />

produces 24 pieces/minute.<br />

The emissions from open processes can be estimated, when <strong>the</strong> volume of <strong>the</strong> mold is<br />

known or can be determined, by calculating <strong>the</strong> total volume of air displaced from <strong>the</strong><br />

operations at <strong>the</strong> temperature of <strong>the</strong> process. A reasonable worst-case estimate of<br />

5-36