TECHNOLOGY STORIES BIKE INFO, GEOMETRY ... - Vintage Trek

TECHNOLOGY STORIES BIKE INFO, GEOMETRY ... - Vintage Trek

TECHNOLOGY STORIES BIKE INFO, GEOMETRY ... - Vintage Trek

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

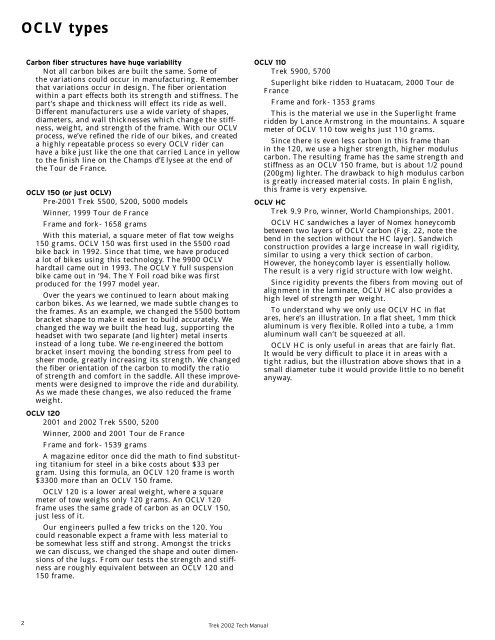

OCLV types<br />

2<br />

Carbon fiber structures have huge variability<br />

Not all carbon bikes are built the same. Some of<br />

the variations could occur in manufacturing. Remember<br />

that variations occur in design. The fiber orientation<br />

within a part effects both its strength and stiffness. The<br />

part’s shape and thickness will effect its ride as well.<br />

Different manufacturers use a wide variety of shapes,<br />

diameters, and wall thicknesses which change the stiffness,<br />

weight, and strength of the frame. With our OCLV<br />

process, we’ve refined the ride of our bikes, and created<br />

a highly repeatable process so every OCLV rider can<br />

have a bike just like the one that carried Lance in yellow<br />

to the finish line on the Champs d’Elysee at the end of<br />

the Tour de France.<br />

OCLV 150 (or just OCLV)<br />

Pre-2001 <strong>Trek</strong> 5500, 5200, 5000 models<br />

Winner, 1999 Tour de France<br />

Frame and fork- 1658 grams<br />

With this material, a square meter of flat tow weighs<br />

150 grams. OCLV 150 was first used in the 5500 road<br />

bike back in 1992. Since that time, we have produced<br />

a lot of bikes using this technology. The 9900 OCLV<br />

hardtail came out in 1993. The OCLV Y full suspension<br />

bike came out in ‘94. The Y Foil road bike was first<br />

produced for the 1997 model year.<br />

Over the years we continued to learn about making<br />

carbon bikes. As we learned, we made subtle changes to<br />

the frames. As an example, we changed the 5500 bottom<br />

bracket shape to make it easier to build accurately. We<br />

changed the way we built the head lug, supporting the<br />

headset with two separate (and lighter) metal inserts<br />

instead of a long tube. We re-engineered the bottom<br />

bracket insert moving the bonding stress from peel to<br />

sheer mode, greatly increasing its strength. We changed<br />

the fiber orientation of the carbon to modify the ratio<br />

of strength and comfort in the saddle. All these improvements<br />

were designed to improve the ride and durability.<br />

As we made these changes, we also reduced the frame<br />

weight.<br />

OCLV 120<br />

2001 and 2002 <strong>Trek</strong> 5500, 5200<br />

Winner, 2000 and 2001 Tour de France<br />

Frame and fork- 1539 grams<br />

A magazine editor once did the math to find substituting<br />

titanium for steel in a bike costs about $33 per<br />

gram. Using this formula, an OCLV 120 frame is worth<br />

$3300 more than an OCLV 150 frame.<br />

OCLV 120 is a lower areal weight, where a square<br />

meter of tow weighs only 120 grams. An OCLV 120<br />

frame uses the same grade of carbon as an OCLV 150,<br />

just less of it.<br />

Our engineers pulled a few tricks on the 120. You<br />

could reasonable expect a frame with less material to<br />

be somewhat less stiff and strong. Amongst the tricks<br />

we can discuss, we changed the shape and outer dimensions<br />

of the lugs. From our tests the strength and stiffness<br />

are roughly equivalent between an OCLV 120 and<br />

150 frame.<br />

<strong>Trek</strong> 2002 Tech Manual<br />

OCLV 110<br />

<strong>Trek</strong> 5900, 5700<br />

Superlight bike ridden to Huatacam, 2000 Tour de<br />

France<br />

Frame and fork- 1353 grams<br />

This is the material we use in the Superlight frame<br />

ridden by Lance Armstrong in the mountains. A square<br />

meter of OCLV 110 tow weighs just 110 grams.<br />

Since there is even less carbon in this frame than<br />

in the 120, we use a higher strength, higher modulus<br />

carbon. The resulting frame has the same strength and<br />

stiffness as an OCLV 150 frame, but is about 1/2 pound<br />

(200gm) lighter. The drawback to high modulus carbon<br />

is greatly increased material costs. In plain English,<br />

this frame is very expensive.<br />

OCLV HC<br />

<strong>Trek</strong> 9.9 Pro, winner, World Championships, 2001.<br />

OCLV HC sandwiches a layer of Nomex honeycomb<br />

between two layers of OCLV carbon (Fig. 22, note the<br />

bend in the section without the HC layer). Sandwich<br />

construction provides a large increase in wall rigidity,<br />

similar to using a very thick section of carbon.<br />

However, the honeycomb layer is essentially hollow.<br />

The result is a very rigid structure with low weight.<br />

Since rigidity prevents the fibers from moving out of<br />

alignment in the laminate, OCLV HC also provides a<br />

high level of strength per weight.<br />

To understand why we only use OCLV HC in flat<br />

ares, here’s an illustration. In a flat sheet, 1mm thick<br />

aluminum is very flexible. Rolled into a tube, a 1mm<br />

aluminum wall can’t be squeezed at all.<br />

OCLV HC is only useful in areas that are fairly flat.<br />

It would be very difficult to place it in areas with a<br />

tight radius, but the illustration above shows that in a<br />

small diameter tube it would provide little to no benefit<br />

anyway.