Beginning the Dialogue - Report on SGR - Federal Transit ...

Beginning the Dialogue - Report on SGR - Federal Transit ...

Beginning the Dialogue - Report on SGR - Federal Transit ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Preventive Maintenance<br />

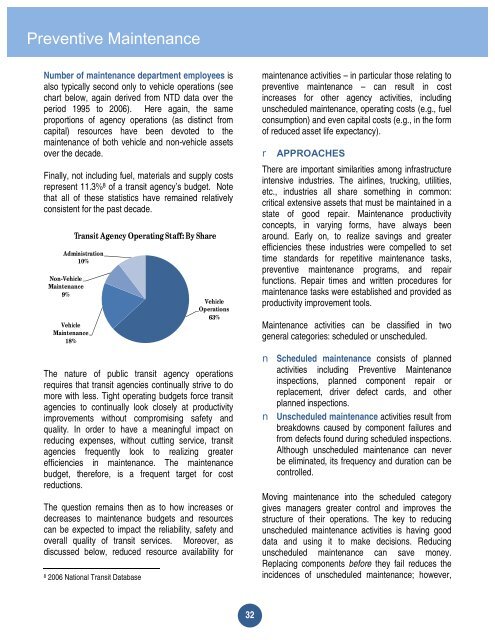

Number of maintenance department employees is<br />

also typically sec<strong>on</strong>d <strong>on</strong>ly to vehicle operati<strong>on</strong>s (see<br />

chart below, again derived from NTD data over <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

period 1995 to 2006). Here again, <str<strong>on</strong>g>the</str<strong>on</strong>g> same<br />

proporti<strong>on</strong>s of agency operati<strong>on</strong>s (as distinct from<br />

capital) resources have been devoted to <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

maintenance of both vehicle and n<strong>on</strong>-vehicle assets<br />

over <str<strong>on</strong>g>the</str<strong>on</strong>g> decade.<br />

Finally, not including fuel, materials and supply costs<br />

represent 11.3% 8 of a transit agency’s budget. Note<br />

that all of <str<strong>on</strong>g>the</str<strong>on</strong>g>se statistics have remained relatively<br />

c<strong>on</strong>sistent for <str<strong>on</strong>g>the</str<strong>on</strong>g> past decade.<br />

<strong>Transit</strong> Agency Operating Staff: By Share<br />

Administrati<strong>on</strong><br />

10%<br />

N<strong>on</strong>-Vehicle<br />

Maintenance<br />

9%<br />

Vehicle<br />

Maintenance<br />

18%<br />

Vehicle<br />

Operati<strong>on</strong>s<br />

63%<br />

The nature of public transit agency operati<strong>on</strong>s<br />

requires that transit agencies c<strong>on</strong>tinually strive to do<br />

more with less. Tight operating budgets force transit<br />

agencies to c<strong>on</strong>tinually look closely at productivity<br />

improvements without compromising safety and<br />

quality. In order to have a meaningful impact <strong>on</strong><br />

reducing expenses, without cutting service, transit<br />

agencies frequently look to realizing greater<br />

efficiencies in maintenance. The maintenance<br />

budget, <str<strong>on</strong>g>the</str<strong>on</strong>g>refore, is a frequent target for cost<br />

reducti<strong>on</strong>s.<br />

The questi<strong>on</strong> remains <str<strong>on</strong>g>the</str<strong>on</strong>g>n as to how increases or<br />

decreases to maintenance budgets and resources<br />

can be expected to impact <str<strong>on</strong>g>the</str<strong>on</strong>g> reliability, safety and<br />

overall quality of transit services. Moreover, as<br />

discussed below, reduced resource availability for<br />

8 2006 Nati<strong>on</strong>al <strong>Transit</strong> Database<br />

32<br />

maintenance activities – in particular those relating to<br />

preventive maintenance – can result in cost<br />

increases for o<str<strong>on</strong>g>the</str<strong>on</strong>g>r agency activities, including<br />

unscheduled maintenance, operating costs (e.g., fuel<br />

c<strong>on</strong>sumpti<strong>on</strong>) and even capital costs (e.g., in <str<strong>on</strong>g>the</str<strong>on</strong>g> form<br />

of reduced asset life expectancy).<br />

r APPROACHES<br />

There are important similarities am<strong>on</strong>g infrastructure<br />

intensive industries. The airlines, trucking, utilities,<br />

etc., industries all share something in comm<strong>on</strong>:<br />

critical extensive assets that must be maintained in a<br />

state of good repair. Maintenance productivity<br />

c<strong>on</strong>cepts, in varying forms, have always been<br />

around. Early <strong>on</strong>, to realize savings and greater<br />

efficiencies <str<strong>on</strong>g>the</str<strong>on</strong>g>se industries were compelled to set<br />

time standards for repetitive maintenance tasks,<br />

preventive maintenance programs, and repair<br />

functi<strong>on</strong>s. Repair times and written procedures for<br />

maintenance tasks were established and provided as<br />

productivity improvement tools.<br />

Maintenance activities can be classified in two<br />

general categories: scheduled or unscheduled.<br />

n Scheduled maintenance c<strong>on</strong>sists of planned<br />

activities including Preventive Maintenance<br />

inspecti<strong>on</strong>s, planned comp<strong>on</strong>ent repair or<br />

replacement, driver defect cards, and o<str<strong>on</strong>g>the</str<strong>on</strong>g>r<br />

planned inspecti<strong>on</strong>s.<br />

n Unscheduled maintenance activities result from<br />

breakdowns caused by comp<strong>on</strong>ent failures and<br />

from defects found during scheduled inspecti<strong>on</strong>s.<br />

Although unscheduled maintenance can never<br />

be eliminated, its frequency and durati<strong>on</strong> can be<br />

c<strong>on</strong>trolled.<br />

Moving maintenance into <str<strong>on</strong>g>the</str<strong>on</strong>g> scheduled category<br />

gives managers greater c<strong>on</strong>trol and improves <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

structure of <str<strong>on</strong>g>the</str<strong>on</strong>g>ir operati<strong>on</strong>s. The key to reducing<br />

unscheduled maintenance activities is having good<br />

data and using it to make decisi<strong>on</strong>s. Reducing<br />

unscheduled maintenance can save m<strong>on</strong>ey.<br />

Replacing comp<strong>on</strong>ents before <str<strong>on</strong>g>the</str<strong>on</strong>g>y fail reduces <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

incidences of unscheduled maintenance; however,