APSS 2013 Proceedings - The University of Sydney

APSS 2013 Proceedings - The University of Sydney

APSS 2013 Proceedings - The University of Sydney

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

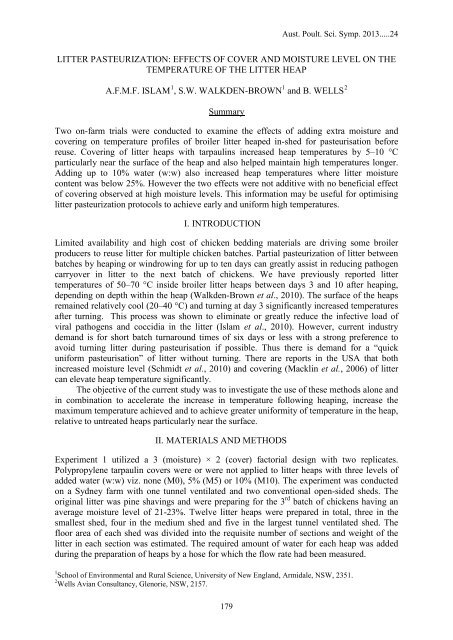

Aust. Poult. Sci. Symp. <strong>2013</strong>.....24<br />

LITTER PASTEURIZATION: EFFECTS OF COVER AND MOISTURE LEVEL ON THE<br />

TEMPERATURE OF THE LITTER HEAP<br />

A.F.M.F. ISLAM 1 , S.W. WALKDEN-BROWN 1 and B. WELLS 2<br />

Summary<br />

Two on-farm trials were conducted to examine the effects <strong>of</strong> adding extra moisture and<br />

covering on temperature pr<strong>of</strong>iles <strong>of</strong> broiler litter heaped in-shed for pasteurisation before<br />

reuse. Covering <strong>of</strong> litter heaps with tarpaulins increased heap temperatures by 5–10 °C<br />

particularly near the surface <strong>of</strong> the heap and also helped maintain high temperatures longer.<br />

Adding up to 10% water (w:w) also increased heap temperatures where litter moisture<br />

content was below 25%. However the two effects were not additive with no beneficial effect<br />

<strong>of</strong> covering observed at high moisture levels. This information may be useful for optimising<br />

litter pasteurization protocols to achieve early and uniform high temperatures.<br />

I. INTRODUCTION<br />

Limited availability and high cost <strong>of</strong> chicken bedding materials are driving some broiler<br />

producers to reuse litter for multiple chicken batches. Partial pasteurization <strong>of</strong> litter between<br />

batches by heaping or windrowing for up to ten days can greatly assist in reducing pathogen<br />

carryover in litter to the next batch <strong>of</strong> chickens. We have previously reported litter<br />

temperatures <strong>of</strong> 50–70 °C inside broiler litter heaps between days 3 and 10 after heaping,<br />

depending on depth within the heap (Walkden-Brown et al., 2010). <strong>The</strong> surface <strong>of</strong> the heaps<br />

remained relatively cool (20–40 °C) and turning at day 3 significantly increased temperatures<br />

after turning. This process was shown to eliminate or greatly reduce the infective load <strong>of</strong><br />

viral pathogens and coccidia in the litter (Islam et al., 2010). However, current industry<br />

demand is for short batch turnaround times <strong>of</strong> six days or less with a strong preference to<br />

avoid turning litter during pasteurisation if possible. Thus there is demand for a “quick<br />

uniform pasteurisation” <strong>of</strong> litter without turning. <strong>The</strong>re are reports in the USA that both<br />

increased moisture level (Schmidt et al., 2010) and covering (Macklin et al., 2006) <strong>of</strong> litter<br />

can elevate heap temperature significantly.<br />

<strong>The</strong> objective <strong>of</strong> the current study was to investigate the use <strong>of</strong> these methods alone and<br />

in combination to accelerate the increase in temperature following heaping, increase the<br />

maximum temperature achieved and to achieve greater uniformity <strong>of</strong> temperature in the heap,<br />

relative to untreated heaps particularly near the surface.<br />

II. MATERIALS AND METHODS<br />

Experiment 1 utilized a 3 (moisture) × 2 (cover) factorial design with two replicates.<br />

Polypropylene tarpaulin covers were or were not applied to litter heaps with three levels <strong>of</strong><br />

added water (w:w) viz. none (M0), 5% (M5) or 10% (M10). <strong>The</strong> experiment was conducted<br />

on a <strong>Sydney</strong> farm with one tunnel ventilated and two conventional open-sided sheds. <strong>The</strong><br />

original litter was pine shavings and were preparing for the 3 rd batch <strong>of</strong> chickens having an<br />

average moisture level <strong>of</strong> 21-23%. Twelve litter heaps were prepared in total, three in the<br />

smallest shed, four in the medium shed and five in the largest tunnel ventilated shed. <strong>The</strong><br />

floor area <strong>of</strong> each shed was divided into the requisite number <strong>of</strong> sections and weight <strong>of</strong> the<br />

litter in each section was estimated. <strong>The</strong> required amount <strong>of</strong> water for each heap was added<br />

during the preparation <strong>of</strong> heaps by a hose for which the flow rate had been measured.<br />

1 School <strong>of</strong> Environmental and Rural Science, <strong>University</strong> <strong>of</strong> New England, Armidale, NSW, 2351.<br />

2 Wells Avian Consultancy, Glenorie, NSW, 2157.<br />

179