Environmentally Degradation of r-PMMA/PMMA-Blend-PU/Ecoflex ...

Environmentally Degradation of r-PMMA/PMMA-Blend-PU/Ecoflex ...

Environmentally Degradation of r-PMMA/PMMA-Blend-PU/Ecoflex ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1038<br />

<strong>Environmentally</strong> <strong>Degradation</strong> <strong>of</strong> r-<strong>PMMA</strong>/<strong>PMMA</strong>-<strong>Blend</strong>-<strong>PU</strong>/Ec<strong>of</strong>lex Sheet<br />

where :<br />

W a is weight <strong>of</strong> sample after extraction;<br />

W b is weight <strong>of</strong> sample before extraction.<br />

2.3.2 Mechanical Tests<br />

The impact strength both Izod and Charpy types<br />

were determined according to ASTM D256 [9] and<br />

ASTM D6110 [10] respectively. The specimens were<br />

tested by using impact strength machine and the energy<br />

<strong>of</strong> hammer was 7.5 J (Impact tester: Italy Cast Type<br />

695700).<br />

2.3.3 The Ultraviolet <strong>Degradation</strong><br />

The ultraviolet degradation was examined according<br />

to QUV-A cabinet from PAN ASIA Industry Co., Ltd.<br />

Thailand standard by detecting the total change in color<br />

from Gretag Macbeth Model COLOR iMATCH,<br />

before and after located in QUV test for 14 days<br />

(according to PAN Asia Industrial Co. Ltd., the 7 days<br />

in QUV-A cabinet was equal to one year). After<br />

ultraviolet degradation r-<strong>PMMA</strong>/<strong>PMMA</strong>-blend-<strong>PU</strong>/<br />

Ec<strong>of</strong>lex sheet was determined the impact strength to<br />

compare the r-<strong>PMMA</strong>/<strong>PMMA</strong>-blend-<strong>PU</strong>/Ec<strong>of</strong>lex sheet<br />

before testing.<br />

2.3.4 <strong>Degradation</strong> <strong>of</strong> r-<strong>PMMA</strong>/<strong>PMMA</strong>-<strong>Blend</strong>-<strong>PU</strong>/<br />

Ec<strong>of</strong>lex Sheet by Landfills<br />

The specimens <strong>of</strong> r-<strong>PMMA</strong>/<strong>PMMA</strong>-blend-<strong>PU</strong>/<br />

Ec<strong>of</strong>lex sheet were taken landfills for six months. The<br />

specimens were buried in covered soil under naturally<br />

condition for biodegradability. After the expiry <strong>of</strong> the<br />

time, the specimens used methods for monitoring in<br />

vitro such as the percentage <strong>of</strong> weight loss and the<br />

surface morphology <strong>of</strong> SEM micrographs. The results<br />

are discussed in more detail below.<br />

2.3.5 Surface Morphology <strong>of</strong> r-<strong>PMMA</strong>/<strong>PMMA</strong>-<br />

<strong>Blend</strong>-<strong>PU</strong>/Ec<strong>of</strong>lex Sheet<br />

A JEOL JSM-5410LV scanning electron<br />

microscope was used to examine the surface<br />

morphology <strong>of</strong> r-<strong>PMMA</strong>/<strong>PMMA</strong>-blend-<strong>PU</strong>/Ec<strong>of</strong>lex<br />

sheet. The specimens were prepared by fracture in<br />

cryogenically in liquid nitrogen.<br />

3. Results and Discussion<br />

3.1 Mechanical Properties <strong>of</strong> r-<strong>PMMA</strong>/<strong>PMMA</strong>-<strong>Blend</strong>-<br />

<strong>PU</strong>/Ec<strong>of</strong>lex Sheet<br />

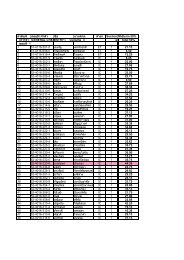

The impact strength property <strong>of</strong> the<br />

r-<strong>PMMA</strong>/<strong>PMMA</strong>-blend-<strong>PU</strong>/Ec<strong>of</strong>lex sheet were<br />

modified poly (methyl methacrylate) sheet with<br />

polyurethane by using IPNs technique (by Izod and<br />

Charpy type) are shown in Table 1. It shows that the<br />

highest impact was observed at MMA:r-<strong>PMMA</strong>:<strong>PU</strong><br />

(72:3:25)/3 EF and (71:4:25)/3 EF, but the impact<br />

strength <strong>of</strong> MMA:r-<strong>PMMA</strong>:<strong>PU</strong> (71:4:25)/3 EF is<br />

higher than MMA:r-<strong>PMMA</strong>:<strong>PU</strong> (72:3:25)/3 EF. This is<br />

probably due to structure <strong>of</strong> EF was ester bond that was<br />

interacted with -NHCOO group on <strong>PMMA</strong>/<strong>PU</strong><br />

polymer networks. This behavior was led EF particle<br />

embedded between polymer networks <strong>of</strong> <strong>PMMA</strong>/<strong>PU</strong><br />

[4]. However, the comparing impact strength <strong>of</strong><br />

r-<strong>PMMA</strong>/<strong>PMMA</strong>-blend-<strong>PU</strong>/Ec<strong>of</strong>lex sheet without EF<br />

was slightly more than r-<strong>PMMA</strong>/<strong>PMMA</strong>-blend-<strong>PU</strong>/<br />

Ec<strong>of</strong>lex sheet with EF. It can be concluded that<br />

r-<strong>PMMA</strong> did not affect impact strength <strong>of</strong> <strong>PMMA</strong>.<br />

Hence, r-<strong>PMMA</strong> has been possible to recycle into<br />

production process, by dissolves within MMA.<br />

3.2 Surface Morphology and Percentage <strong>of</strong> IPNs <strong>of</strong><br />

Impact Modified <strong>PMMA</strong> Sheet<br />

The percentage <strong>of</strong> IPNs that were estimated by<br />

solvent extraction to determine grafted MMA<br />

monomer and uncross-linking <strong>PMMA</strong> in the final<br />

product are shown in Table 1, shown<br />

MMA:r-<strong>PMMA</strong>:<strong>PU</strong> (71:4:25)/3 EF was the highest<br />

percentage <strong>of</strong> IPNs when compared with other amount<br />

<strong>of</strong> EF monomer in casting process.<br />

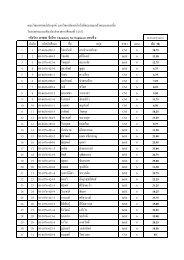

The results <strong>of</strong> surface morphology by SEM<br />

(scanning electron microscope) <strong>of</strong> r-<strong>PMMA</strong>/<strong>PMMA</strong>blend-<strong>PU</strong>/Ec<strong>of</strong>lex<br />

sheet were shown in Fig. 2.<br />

The r-<strong>PMMA</strong>/<strong>PMMA</strong>-blend-<strong>PU</strong>/Ec<strong>of</strong>lex sheet<br />

consists <strong>of</strong> the previously polymer from r-<strong>PMMA</strong>