Environmentally Degradation of r-PMMA/PMMA-Blend-PU/Ecoflex ...

Environmentally Degradation of r-PMMA/PMMA-Blend-PU/Ecoflex ...

Environmentally Degradation of r-PMMA/PMMA-Blend-PU/Ecoflex ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

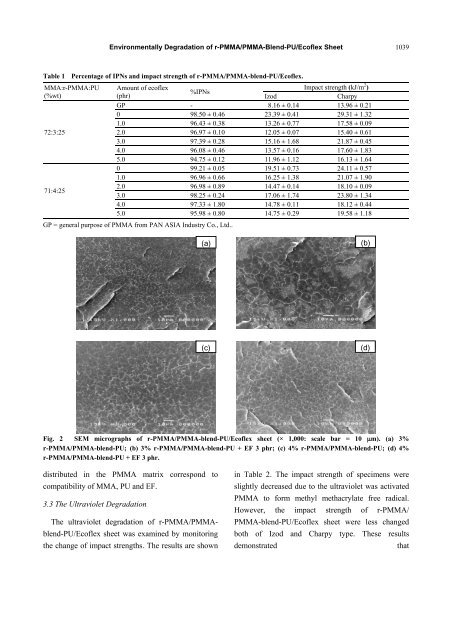

<strong>Environmentally</strong> <strong>Degradation</strong> <strong>of</strong> r-<strong>PMMA</strong>/<strong>PMMA</strong>-<strong>Blend</strong>-<strong>PU</strong>/Ec<strong>of</strong>lex Sheet 1039<br />

Table 1 Percentage <strong>of</strong> IPNs and impact strength <strong>of</strong> r-<strong>PMMA</strong>/<strong>PMMA</strong>-blend-<strong>PU</strong>/Ec<strong>of</strong>lex.<br />

MMA:r-<strong>PMMA</strong>:<strong>PU</strong><br />

(%wt)<br />

72:3:25<br />

71:4:25<br />

Amount <strong>of</strong> ec<strong>of</strong>lex<br />

Impact strength (kJ/m 2 )<br />

%IPNs<br />

(phr)<br />

Izod<br />

Charpy<br />

GP - 8.16 ± 0.14 13.96 ± 0.21<br />

0 98.50 ± 0.46 23.39 ± 0.41 29.31 ± 1.32<br />

1.0 96.43 ± 0.38 13.26 ± 0.77 17.58 ± 0.09<br />

2.0 96.97 ± 0.10 12.05 ± 0.07 15.40 ± 0.61<br />

3.0 97.39 ± 0.28 15.16 ± 1.68 21.87 ± 0.45<br />

4.0 96.08 ± 0.46 13.57 ± 0.16 17.60 ± 1.83<br />

5.0 94.75 ± 0.12 11.96 ± 1.12 16.13 ± 1.64<br />

0 99.21 ± 0.05 19.51 ± 0.73 24.11 ± 0.57<br />

1.0 96.96 ± 0.66 16.25 ± 1.38 21.07 ± 1.90<br />

2.0 96.98 ± 0.89 14.47 ± 0.14 18.10 ± 0.09<br />

3.0 98.25 ± 0.24 17.06 ± 1.74 23.80 ± 1.34<br />

4.0 97.33 ± 1.80 14.78 ± 0.11 18.12 ± 0.44<br />

5.0 95.98 ± 0.80 14.75 ± 0.29 19.58 ± 1.18<br />

GP = general purpose <strong>of</strong> <strong>PMMA</strong> from PAN ASIA Industry Co., Ltd..<br />

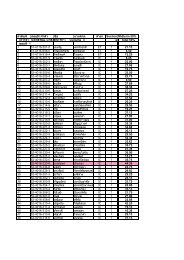

(a)<br />

(b)<br />

(c)<br />

(d)<br />

Fig. 2 SEM micrographs <strong>of</strong> r-<strong>PMMA</strong>/<strong>PMMA</strong>-blend-<strong>PU</strong>/Ec<strong>of</strong>lex sheet (× 1,000: scale bar = 10 m). (a) 3%<br />

r-<strong>PMMA</strong>/<strong>PMMA</strong>-blend-<strong>PU</strong>; (b) 3% r-<strong>PMMA</strong>/<strong>PMMA</strong>-blend-<strong>PU</strong> + EF 3 phr; (c) 4% r-<strong>PMMA</strong>/<strong>PMMA</strong>-blend-<strong>PU</strong>; (d) 4%<br />

r-<strong>PMMA</strong>/<strong>PMMA</strong>-blend-<strong>PU</strong> + EF 3 phr.<br />

distributed in the <strong>PMMA</strong> matrix correspond to<br />

compatibility <strong>of</strong> MMA, <strong>PU</strong> and EF.<br />

3.3 The Ultraviolet <strong>Degradation</strong><br />

The ultraviolet degradation <strong>of</strong> r-<strong>PMMA</strong>/<strong>PMMA</strong>blend-<strong>PU</strong>/Ec<strong>of</strong>lex<br />

sheet was examined by monitoring<br />

the change <strong>of</strong> impact strengths. The results are shown<br />

in Table 2. The impact strength <strong>of</strong> specimens were<br />

slightly decreased due to the ultraviolet was activated<br />

<strong>PMMA</strong> to form methyl methacrylate free radical.<br />

However, the impact strength <strong>of</strong> r-<strong>PMMA</strong>/<br />

<strong>PMMA</strong>-blend-<strong>PU</strong>/Ec<strong>of</strong>lex sheet were less changed<br />

both <strong>of</strong> Izod and Charpy type. These results<br />

demonstrated<br />

that