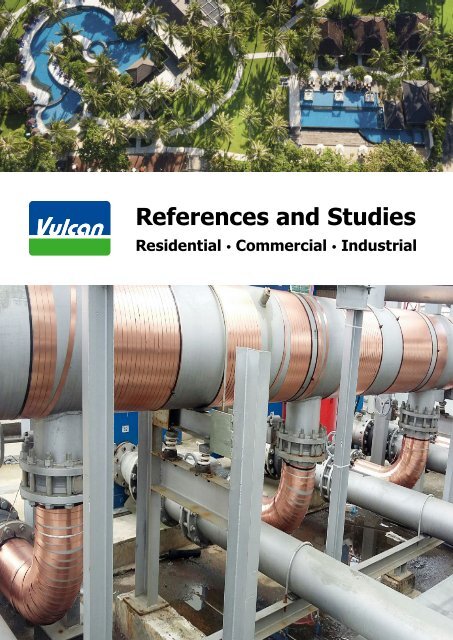

Vulcan Anti-Scale System - Reference Book (EN)

Vulcan is the salt-free alternative to water softeners. Vulcan is an eco-friendly water treatment system that protects your piping system and appliances against scale deposits and rust - no use of any salt or chemicals. The Vulcan reference book shows a selection of installations and studies of the Vulcan water treatment.

Vulcan is the salt-free alternative to water softeners. Vulcan is an eco-friendly water treatment system that protects your piping system and appliances against scale deposits and rust - no use of any salt or chemicals. The Vulcan reference book shows a selection of installations and studies of the Vulcan water treatment.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Reference</strong>s and Studies<br />

Residential • Commercial • Industrial

Contents<br />

Restaurants and Kitchens<br />

Mövenpick Restaurant (ice cream machine) ......................................................................................2<br />

McDonaldʻs................................................................................................................................3<br />

O2 Water Margin Restaurant (kitchen, sanitary).................................................................................4<br />

Waffle House.............................................................................................................................5<br />

TA Truck Stop (sanitary, kitchen, boiler)..............................................................................................6<br />

White Castle Burger Restaurant (kitchen, ice machine) .......................................................................7<br />

Kitchen of Spokane School (steam oven).........................................................................................8<br />

Grease Trap in a Kitchen.............................................................................................................9<br />

Cake Factory (grease trap).............................................................................................................10<br />

Metro Food Store (bread oven).......................................................................................................11<br />

Hospitality<br />

InterContinental (kitchen, steamer)..................................................................................................14<br />

Hyatt Regency (kitchen, steamer).....................................................................................................15<br />

Ibis (hot water line & tank)................................................................................................................16<br />

Ibis Budget (water heater)..............................................................................................................17<br />

Hotel Acacia (chiller, cooling tower)....................................................................................................18<br />

Palm Beach Hotel (boiler).............................................................................................................19<br />

Barcelo Bavaro Palace (chiller, cooling tower, tank)...............................................................................20<br />

Lhasa 21 Inn (solar water heating)....................................................................................................21<br />

Furama Hotel Dalian (heat exchanger)..............................................................................................22<br />

Royalton Splash Punta Cana (cooling tower, hot water system)...............................................................23<br />

Hotel Meridien N׳Fis (pool & spa)....................................................................................................24<br />

Karnavati Club Hotel (pool, water softener)........................................................................................25<br />

Holiday Resort (water heater, laundry, sanitary, kitchen)..........................................................................26<br />

Aura Hotel (kitchen)......................................................................................................................27<br />

Schools, Educational Institutions and Sporting Facilities<br />

FAMU/FSU College of Engineering (cooling tower).............................................................................30<br />

Spokane Public Schools Washington (cooling tower, piping system)........................................................31<br />

Florida State University (rack washer, steam washer)............................................................................32<br />

Beijing University of Chemical Technology (sanitary, water heater).......................................................33<br />

Prince Sattam bin Abdulaziz University.........................................................................................34<br />

Irrigation for a Football Field.......................................................................................................35<br />

Hartwall Ice Hockey Arena (heating & cooling equipment).....................................................................36<br />

Powerhouse Gym.......................................................................................................................37<br />

Ice Stadium Neuchâtel (ice resurfacer).............................................................................................38<br />

Ice Land Stadium (ice production)...................................................................................................39<br />

Production and Industries<br />

Coca Cola (pipe, filter)...................................................................................................................42<br />

Nestlé (ice cream factory) (hot water tank, filter, cleaning-in-place machine)...............................................43<br />

Yinmore Sugar Industry (syrup processing, fermenter, boiler, tank, filter, distillation, water softener)....................44<br />

Yunnan Salt Industry (heat exchanger).............................................................................................45<br />

Winery Adam Müller ..................................................................................................................46<br />

Dairy Farm Rancho Dulce María ..................................................................................................47

Delice Danone (dairy production).................................................................................................48<br />

Delicatessen Food Processing Plant (boiler, heat exchanger, sterilizer, water softener)..................................49<br />

Noon Crop Science (cooling tower, condenser tubes).............................................................................50<br />

Medicine Factory (cooling tower, heat exchanger)..................................................................................51<br />

Marigot / Swarovski (cooling tower, chiller, process water).......................................................................52<br />

Nippon Sheet Glass Factory (cooling tower, stirrer).............................................................................53<br />

Beauty Star Plastic Packaging (injection molding machine, heat exchanger, cooling tower, chiller)......................54<br />

TDK Electronics (RO membrane, cooling system)...................................................................................55<br />

Shengli Oilfield Petroleum Plant (heat exchanger)..............................................................................56<br />

HYUNDAI (circulating water, cooling tower, induction hardening machine).......................................................57<br />

CHRYSLER (high pressure wash station)..............................................................................................58<br />

HONDA (circulating water, casting, production robots)...............................................................................59<br />

Huomei Wheel Manufacture (RO membrane)....................................................................................60<br />

Suining New Oasis Printing & Dyeing Factory (dyeing system, sludge dewatering system)...........................61<br />

Toray Industries (plate heat exchanger).............................................................................................62<br />

Holcim Cement Factory (oil heat exchanger, water softener)...................................................................63<br />

Huixi Metal and Steel (chiller)........................................................................................................64<br />

Beihai Thermal Power Plant (heat pump station, cooling water)...............................................................65<br />

Miscellaneous<br />

Cost Savings for Cooling Towers..................................................................................................68<br />

Supermal Karawaci (4-year cooling tower test, heat exchanger, condenser tubes)............................................69<br />

The Be’er Sheva Grand Mall (cooling tower, heat exchanger)..................................................................70<br />

Tangshan Kailuan Group Linxi Mining (underground pump room)...........................................................71<br />

Energy Complex Office Building (cooling tower, chiller)........................................................................72<br />

Średzki Water Park (pool, heating system)..........................................................................................73<br />

Avril Supermarket (greenhouse, drippers)...........................................................................................74<br />

Paris Country Golf Club (kitchen, sanitary)........................................................................................75<br />

Pilbara Commercial Laundry Services (air conditioning, hot water supply).................................................76<br />

Mc Clean Public Toilet Center......................................................................................................77<br />

Hammam (public bathhouse, hot water tank).........................................................................................78<br />

Riverview Hospital (pool chlorinator)................................................................................................79<br />

Phillip Best Plumbing (heating system, combustion oven)........................................................................80<br />

Garden Shop (plant cultivator, irrigation).............................................................................................81<br />

Poultry Farms (cooling tower)..........................................................................................................82<br />

Cattle Farm (feeder, drinker, water supply)...........................................................................................83<br />

Long-Term Care Centers (hot water tank).........................................................................................84<br />

Maternity Home (water softener, dishwasher, sanitary)............................................................................85<br />

Residential Installations and Apartment Buildings<br />

<strong>Vulcan</strong> in Apartment Buildings (test report, kitchen, sanitary)................................................................88<br />

Garden Sprinkler <strong>System</strong>s (irrigation)..............................................................................................90<br />

Hairdresser Recommendation Letter (kitchen, sanitary).....................................................................91<br />

Residence Building (kitchen, sanitary)...............................................................................................92<br />

Steinbeis Institute (household equipment test)....................................................................................93<br />

Residential Client from Bünden....................................................................................................94<br />

Residential Client from Ottobrun..................................................................................................95

<strong>Vulcan</strong> <strong>Reference</strong> Database<br />

This reference book shows only an excerpt<br />

of the available <strong>Vulcan</strong> references.<br />

All <strong>Vulcan</strong> references from world-wide you can<br />

see and download at:<br />

www.cwt-vulcan.com/reference<br />

There you can also search references by keyword,<br />

country or <strong>Vulcan</strong> model.<br />

PDF Download and Online Live View<br />

<strong>Vulcan</strong> <strong>Reference</strong> <strong>Book</strong><br />

Online live view: www.bit.ly/rben-web<br />

<strong>Vulcan</strong> Cooling Tower <strong>Reference</strong> <strong>Book</strong><br />

Online live view: www.bit.ly/rbcten-web<br />

Download PDF: www.bit.ly/vrben Download PDF: www.bit.ly/vrbcten

1<br />

Restaurants<br />

and<br />

Kitchens

2<br />

Mövenpick Restaurant<br />

Germany<br />

Mövenpick Restaurant<br />

Potsdam<br />

Christiani Wassertechnik GmbH<br />

<strong>Reference</strong> Letter<br />

Dear Sir,<br />

Our Mövenpick Restaurant opened in January 2000. After a short period, we noticed a high level<br />

of limescale developing on the ice-cream makers. These calcifications could only be cleared bit by<br />

bit which is a time-consuming process. To avoid potential losses, a short-term limescale filter was<br />

installed. The operating time of this filter is limited however and thus resulted in high costs.<br />

At a trade fair visit, we consulted the company Christiani Wassertechnik GmbH about other possibilities.<br />

We installed the limescale converter <strong>Vulcan</strong> 5000 and the ice-cream makers have been functioning<br />

smoothly for 10 months now.<br />

The limescale, which accumulates especially in the crushed ice makers, can now be easily removed<br />

as it is converted into fine-grained structures.<br />

We wish the company Christiani further success with their excellent products.<br />

Yours Sincerely,<br />

Marcel Charrier<br />

Director<br />

<strong>Vulcan</strong> 5000<br />

<strong>Vulcan</strong> protects the ice<br />

machine<br />

<strong>Vulcan</strong> protects the icecream<br />

makers<br />

Soft limescale is now easily<br />

removed<br />

Mövenpick Restaurant, Potsdam<br />

www.moevenpick.com | Mövenpick Restaurants Deutschland GmbH

3<br />

McDonaldʻs<br />

Ukraine<br />

McDonald‘s Ukraine Ltd.<br />

Kiev<br />

www.mcdonalds.ua<br />

Dear Mr. Christiani,<br />

Thank you very much for your service to ”McDonald‘s Ukraine Ltd.”<br />

From our side, we‘re very grateful for your cooperation and support throughout the<br />

last 10 years.<br />

Our company began to operate in Ukraine in 1987. Since then, we‘ve already opened<br />

57 McDonald‘s restaurants.<br />

In all of these restaurants, we have installed the <strong>Vulcan</strong> Descaler by CWT International,<br />

which has delivered consistent results throughout each site.<br />

The <strong>Vulcan</strong> range is easily installed and has been a very useful addition to our<br />

company.<br />

I would like to add that the support of CWT International is very important to us here<br />

at McDonald‘s Ukraine.<br />

Best regards,<br />

Eugene Molodid<br />

Equipment Coordinator<br />

McDonald's Ukraine Ltd

4<br />

O2 Water Margin Restaurant<br />

United Kingdom<br />

The O2 <br />

Date: 18th August 2014 <br />

To whom it may concern, <br />

The O2 <br />

We are a very busy 300-‐seat restaurant at the 02 London Arena and have had major <br />

problems in the past with lime scale in our glass and line washing machines, sinks, food <br />

The O2 <br />

warmers and toilets. We have installed various products in the past to remove this scale <br />

with little success, resulting in higher maintenance and replacement costs along with <br />

To whom it may concern,<br />

increased Date: 18th expenses August on 2014 cleaning equipment. <br />

We are a very<br />

To whom it may Date:<br />

busy<br />

concern, 18th<br />

300-seat<br />

August 2014<br />

restaurant<br />

<br />

at the O2 London Arena and have had major problems in<br />

Since<br />

the<br />

CWT<br />

past<br />

Partners<br />

with limescale<br />

Ltd installed<br />

in<br />

the<br />

our<br />

<strong>Vulcan</strong><br />

glass<br />

S25<br />

and<br />

at<br />

line<br />

our <br />

washing<br />

premises we<br />

machines,<br />

have noticed<br />

sinks,<br />

<br />

food warmers and toilets. We<br />

substantial<br />

have installed<br />

and continual<br />

various<br />

improvement<br />

products<br />

<br />

in<br />

over<br />

the<br />

the<br />

past<br />

past<br />

to<br />

3 months.<br />

remove<br />

Our<br />

this<br />

food<br />

scale<br />

warmers,<br />

with little<br />

steam<br />

success,<br />

<br />

resulting in higher<br />

We are a very <br />

To<br />

busy<br />

whom<br />

300-‐seat<br />

it may<br />

restaurant<br />

concern, <br />

ovens, at the 02 London Arena and have had major <br />

maintenance kitchen sinks and and replacement restrooms are costs clear of along scale, with along increased with cleaner expenses crockery and on cleaning equipment.<br />

cutlery. problems This in has the helped past with to reduce lime scale the detergent in our glass and and cleaning line washing equipment machines, and products, sinks, food <br />

warmers and toilets.<br />

We are<br />

<br />

<br />

We<br />

a very<br />

have<br />

busy<br />

installed<br />

300-‐seat various<br />

restaurant<br />

products<br />

at the<br />

in <br />

<br />

the<br />

02 <br />

<br />

London<br />

past to <br />

remove<br />

Arena and<br />

this<br />

have<br />

scale<br />

had<br />

<br />

major <br />

which Since has CWT saved Partners us more than Ltd the installed cost of installing the <strong>Vulcan</strong> the S25 <strong>Vulcan</strong> at S25. our The premises restaurant we have now noticed a substantial and<br />

with little success,<br />

problems<br />

resulting<br />

in the<br />

in<br />

past<br />

higher<br />

with<br />

maintenance<br />

lime scale in<br />

and<br />

our<br />

replacement<br />

glass and line<br />

costs<br />

washing<br />

along<br />

machines, with <br />

sinks, food <br />

able continual to operate improvement at a higher level, over avoiding the past lime scale 3 months. and rewashing Our food of dishes, warmers, with far steam ovens, kitchen sinks and<br />

increased expenses<br />

warmers<br />

on <br />

cleaning<br />

and toilets.<br />

equipment.<br />

We have installed various products in the past to remove this scale <br />

fewer restrooms complaints are from clear customers. of scale, along with cleaner crockery and cutlery. This has helped to reduce the<br />

with little success, resulting in higher maintenance and replacement costs along with <br />

detergent and cleaning equipment and products, which has saved us more than the cost of installing<br />

increased expenses on cleaning equipment. <br />

It is Since a pleasure CWT Partners to inform Ltd you installed that we the have <strong>Vulcan</strong> are S25 very at satisfied our premises with the we <strong>Vulcan</strong> have noticed S25 descaling <br />

the <strong>Vulcan</strong> S25. The restaurant is now able to operate at a higher level, avoiding limescale and<br />

unit. substantial Additionally, and we continual would improvement like to single out over the the professionalism past 3 months. of Our the food CWT warmers, team that steam <br />

rewashing of dishes, with far fewer complaints from customers.<br />

Since CWT Partners Ltd installed the <strong>Vulcan</strong> S25 at our premises we have noticed <br />

addressed ovens, kitchen our lime sinks scale and problem restrooms and are like clear to thank of scale, them along for all with their cleaner help. We crockery highly and <br />

substantial and continual improvement over the past 3 months. Our food warmers, steam <br />

recommend cutlery.<br />

lt is a pleasure<br />

This the has <strong>Vulcan</strong> helped<br />

to inform water to reduce treatment you that<br />

the detergent<br />

we and are urge very others and<br />

satisfied cleaning clients equipment to with install the it. <strong>Vulcan</strong><br />

and products,<br />

S25 descaling<br />

<br />

unit. Additionally,<br />

ovens, kitchen sinks and restrooms are clear of scale, along with cleaner crockery and <br />

which<br />

we would<br />

has saved<br />

like<br />

us<br />

to<br />

more<br />

single<br />

than <br />

out<br />

the cost<br />

the<br />

of<br />

professionalism<br />

installing the <strong>Vulcan</strong><br />

of<br />

S25.<br />

the<br />

The<br />

CWT<br />

restaurant<br />

team<br />

<br />

that<br />

is now<br />

addressed<br />

<br />

our limescale<br />

cutlery. This has helped to reduce the detergent and cleaning equipment and products, <br />

able<br />

problem<br />

to operate<br />

and<br />

at<br />

like<br />

a higher<br />

to thank<br />

level,<br />

them<br />

avoiding<br />

for<br />

lime<br />

all their<br />

scale<br />

help.<br />

and rewashing<br />

We highly<br />

of dishes,<br />

recommend<br />

with far<br />

the <strong>Vulcan</strong> water treatment<br />

which has saved us more than the cost of installing the <strong>Vulcan</strong> S25. The restaurant is now <br />

fewer<br />

and urge<br />

complaints<br />

other<br />

from<br />

clients<br />

customers.<br />

to install<br />

<br />

it.<br />

able to operate at a higher level, avoiding lime scale and rewashing of dishes, with far <br />

Yours sincerely, <br />

fewer complaints from customers. <br />

Yours It is a pleasure sincerely, to inform you that we have are very satisfied with the <strong>Vulcan</strong> S25 descaling <br />

unit. Additionally, we would like to single out the professionalism of the CWT team that <br />

It is a pleasure to inform you that we have are very satisfied with the <strong>Vulcan</strong> S25 descaling <br />

addressed our lime scale problem and like to thank them for all their help. We highly <br />

unit. Additionally, we would like to single out the professionalism of the CWT team that <br />

recommend Chin Lam the <strong>Vulcan</strong> water treatment and urge others clients to install it. <br />

addressed our lime scale problem and like to thank them for all their help. We highly <br />

Chin CEO Lam<br />

CEO<br />

recommend the <strong>Vulcan</strong> water treatment and urge others clients to install it. <br />

Yours sincerely, <br />

Novari (at the O2) LIMITED<br />

Registered office: 23 Entertainment Avenue, The O2, Greenwich, London,<br />

SE10 0DY<br />

Chin Lam<br />

CEO<br />

Yours sincerely, <br />

Chin Lam<br />

CEO<br />

Tel: 020 88584510 Fax: 020 88589696<br />

Registered in England No. 8316802<br />

Novari (at the O2) LIMITED<br />

Novari (at the O2) LIMITED<br />

Registered office: 23 Entertainment Avenue, The O2, Greenwich, London,<br />

SE10 0DY<br />

Registered office: 23 Entertainment Avenue, The O2, Greenwich, London,<br />

Tel: 020 88584510 Fax: 020 88589696<br />

Registered in England No. 8316802<br />

SE10 0DY<br />

Tel: 020 88584510 Fax: 020 88589696<br />

Registered in England No. 8316802

5<br />

Waffle House<br />

USA<br />

Installation Details<br />

Model:<br />

<strong>Vulcan</strong> S25<br />

Location:<br />

Waffle House<br />

Tallahassee<br />

Florida<br />

www.wafflehouse.com<br />

Area:<br />

Water main<br />

Installed by:<br />

Ackruitlabs, Inc.

6<br />

TA Truck Stop (Moriarty, New Mexico)<br />

USA<br />

Moriarty Travel Center<br />

Here in Moriarty N.M. we have extremely hard water.<br />

In our truck stop we have to always clean up after it.<br />

The showers are a particular problem. From clogged<br />

shower heads, to constant cleaning and scrubbing to<br />

keep them clean.<br />

It also wreaks havoc with the boilers and water heaters.<br />

After Andy and <strong>Vulcan</strong> Water Products installed the<br />

S100 unit on the main line, we noticed real soon, that the<br />

showers were becoming cleaner, and the discoloration<br />

in the water was gone too!<br />

In our Country Pride restaurant, they noticed a dramatic<br />

change in the color and clarity of the iced tea and<br />

coffee, cleaner, spotless glassware and dishes, and the<br />

ice machine makes clean ice! We are very pleased with<br />

the results. Thank you <strong>Vulcan</strong>!<br />

Signed,<br />

John Hathaway GM<br />

Jack Reneker AGM<br />

TA Operating LLC<br />

Moriarty, NM 87035<br />

<strong>Vulcan</strong> S100 installed on the main water line

7<br />

White Castle Burger Restaurant (New York)<br />

USA<br />

SLIDER EXPERTS<br />

SINCE 1921<br />

Installation Details<br />

<strong>Vulcan</strong> 3000 mounted<br />

Location: White Castle #32<br />

New York, USA<br />

www.whitecastle.com<br />

Model/Area:<br />

Result:<br />

<strong>Vulcan</strong> 3000 was installed on<br />

the ice machine after the carbon<br />

filters.<br />

<strong>Vulcan</strong> 5000 was installed on the<br />

main inlet line.<br />

The calcium was completely<br />

removed in one area, and normal<br />

equipment cleaning schedules are<br />

prolonged.<br />

30 plus White Castle have units<br />

installed. The newer restaurants<br />

have a <strong>Vulcan</strong> S10 installed on the<br />

inlet main.<br />

Installed by: Salt-Free Water <strong>System</strong>s LLC<br />

www.vulcan-USA.com<br />

<strong>Vulcan</strong> 5000 on main water inlet<br />

Pan before <strong>Vulcan</strong> installation, hard calcium and<br />

etched line present.<br />

After <strong>Vulcan</strong> installation ― pan area is now<br />

completely scale-free. There is a slight indentation<br />

into the pan at the waterline.

8<br />

Kitchen of Spokane School<br />

USA<br />

<strong>Vulcan</strong> in a School Kitchen<br />

Dear CWT Team,<br />

The steam convection oven has greatly improved since<br />

the installation of the <strong>Vulcan</strong>. The water is injected via<br />

the pipe in the centre of the heating coils and a fan inside<br />

the coils blows the water through the coils and comes<br />

out as steam. The operating temperature of this device is<br />

350F (180°C). The white material you see on the coils is<br />

a powder coating that is easily removed with a wet cloth.<br />

No more chemicals are required to clean the convection<br />

oven.<br />

However, we have noticed even greater results in the<br />

school kitchen, which was previously using a traditional<br />

water softening system. But all in all, we can confirm the<br />

effectiveness of the <strong>Vulcan</strong> treatment, which means less<br />

work for the maintenance staff.<br />

The <strong>Vulcan</strong> unit installed on the entire building system<br />

has also been extremely effective. No more rusty water<br />

after weekends and Christmas break. The next <strong>Vulcan</strong><br />

will be installed on the other school buildings, which are<br />

around 20 – 25 years old.<br />

The last <strong>Vulcan</strong> unit is installed on the main cooling tower<br />

– we have had nothing but positive news in regards to<br />

this installation. We will be seeing more orders coming<br />

from this customer very soon.<br />

Best Regards<br />

Arne Vestad<br />

International Water Treatment NA LLC<br />

Washington, USA

9<br />

Grease Trap in a Kitchen<br />

Japan<br />

Grease Trap in a Kitchen<br />

3 Months Test<br />

To alleviate the overflow of drainage out of the basket due to oil balls in the grease trap under the<br />

sink of the counter in the cookery on the fifth floor of the building. Also, to save the administrative<br />

and maintenance expenses by reducing the periodical cleanings used to be conducted several<br />

times a year. Pipe Size: 50 mm | <strong>Vulcan</strong> Model: <strong>Vulcan</strong> 5000<br />

June 13th | Before <strong>Vulcan</strong> installation<br />

Usual level of standing water.<br />

June 17th | Installation of <strong>Vulcan</strong><br />

For treating water in the cookery on the fifth floor, <strong>Vulcan</strong> is<br />

installed on the vertical piping in the warehouse where the<br />

nearest main water pipe is exposed. The effectiveness of the<br />

<strong>Vulcan</strong> appears in all the service water on the fifth floor that is<br />

supplied through this piping.<br />

Verification of the effectiveness<br />

Grease trap under the countertop<br />

The status of the grease trap upon installation of the <strong>Vulcan</strong><br />

was confirmed, and the changes of the statuses were<br />

observed for approximately five months from the start of<br />

the operation. In almost all cases, the effectiveness can be<br />

confirmed through the observation for about 3 months.<br />

September 12th<br />

Sept. 20th - Before cleaning<br />

Sept. 20th - After cleaning<br />

The basket after being washed by hosing.<br />

The portions usually being contacted with<br />

the treated water are cleaned easily with a<br />

water flow from the tap.<br />

The status after being used without cleaning<br />

since the installation in June (no adhered<br />

materials are seen on the portions usually<br />

contacting with water).<br />

Grease trap was cleaned with water flow<br />

under the sink.<br />

Similar effects have been reported at drainages in food factories, restaurants and kitchens. Many <strong>Vulcan</strong> installations showed that<br />

the treated water had substantial cleaning effect even with extremely reduction of conventionally used detergents. There were<br />

even some cases where the use of detergent (such as cationic detergent) causes a buildup of a thin film of dirt. Cationic detergents<br />

should not be used. With the portions that do not contact with the treatment water, this effect cannot be expected. <strong>Vulcan</strong> has no<br />

effect of breaking or resolving solids in drainage. Although the <strong>Vulcan</strong> has no disinfection effect, its prevention of dirt from adhering<br />

to the basket and the net contributes to the reduction of mold‘s food source.<br />

www.catalina.co.jp<br />

23-11, 3 Chome, Nishibori Sakura-KuSaitama-Shi Saitama Pref 338 - 0832 Japan<br />

EXCLUSIVE PARTNER

10<br />

Grease Traps in a Cake Factory<br />

Japan<br />

<strong>Vulcan</strong> for Grease Traps<br />

3 Months Test Report<br />

in a cake factory in Kanagawa, Japan<br />

<strong>Vulcan</strong> has a trouble free design and easy installation. The LED light<br />

always blinks dependably as it shows the processing conditions.<br />

I have compared the state of the grease trap before and after<br />

installing the <strong>Vulcan</strong>. Before installation, I noticed strong odors<br />

when opening the hole. When I opened the hole one month after<br />

the installation, no such odors were present.<br />

As for the cleaning intervals, monthly cleaning may now not be<br />

required. The effect and cleaning intervals of <strong>Vulcan</strong> will require an<br />

annual observation, however, I believe the amount of cleaning will<br />

be reduced remarkably.<br />

<strong>Vulcan</strong> 5000 was installed in the<br />

factory kitchen<br />

February 16th - Start situation before <strong>Vulcan</strong> was installed<br />

Grease Trap<br />

50 mm thick oil layer<br />

Cleaned Grease Trap<br />

March 22nd<br />

1 month with <strong>Vulcan</strong><br />

May 18th - 3 months with <strong>Vulcan</strong> treatment<br />

30 - 40 mm thick oil layer 2nd Tank - 10 mm thick oil layer 1st Tank<br />

www.catalina.co.jp<br />

23-11, 3 Chome, Nishibori Sakura-KuSaitama-Shi Saitama Pref 338 - 0832 Japan<br />

EXCLUSIVE PARTNER

11<br />

Metro Food Store<br />

Canada<br />

<strong>Vulcan</strong> Effect in the Bread Oven<br />

Installation Details<br />

Location:<br />

A metro food store<br />

Québec, Canada<br />

Model: <strong>Vulcan</strong> 5000<br />

Treatment area: The bread oven<br />

Problem:<br />

Installed by:<br />

Often reparation and needed to<br />

clean manually<br />

Gestion L.B. Inc<br />

<strong>Vulcan</strong> 5000<br />

Remove the insulation cotton and install<br />

the impulse bands.<br />

The bread oven before <strong>Vulcan</strong> installation.<br />

The scale deposits were cleaned and<br />

<strong>Vulcan</strong> 5000 was installed.<br />

<strong>Vulcan</strong> effect<br />

After 6 months with <strong>Vulcan</strong>, very little scale<br />

has been formed.

Hospitality<br />

13

14<br />

InterContinental Kunming<br />

China<br />

HOTELS & RESORTS<br />

Installation Details<br />

Location:<br />

Model:<br />

Area:<br />

Purpose:<br />

*****<br />

InterContinental Kunming<br />

www.ihg.com/intercontinental<br />

<strong>Vulcan</strong> S10<br />

The water main of the kitchen<br />

Gently solve the scaling problems of the<br />

entire kitchen water system: the reduced<br />

water volume, the increased water pressure,<br />

the clogging of the dishwasher outlet, the<br />

scaling of the steamer, the low heating<br />

efficiency, the increased maintenance and<br />

the reduced overall effi ciency.<br />

<strong>Vulcan</strong> S10 was installed<br />

in the main water pipe of<br />

the restaurant kitchen<br />

The untreated steamer<br />

The steamer after using <strong>Vulcan</strong> S10 for 2 months<br />

The scale was in flakes and could not be drained out<br />

of the steamer‘s drain hole. To test the effectiveness<br />

of the <strong>Vulcan</strong> system, no cleaning process was<br />

carried out before installing the <strong>Vulcan</strong> S10.<br />

The scale has been completely turned into powder,<br />

so there is no need to open it for cleaning, just by<br />

operating the regular drainage function, it can keep<br />

the hot water tank clean and free of scale. Due to the<br />

good results, the cooperation will also be carried out<br />

in the hotel‘s hot water supply system and central air<br />

conditioning system.<br />

www.vulcan-ailong.com<br />

EXCLUSIVE PARTNER

15<br />

Hyatt Regency Xi’an<br />

China<br />

Hyatt Regency Xi'an is a five-star hotel located on the side of Qujiang South Lake. It has a lake view and is in<br />

the middle of the city with the comfort and quiet. Most rooms have a separate balcony and lake view.<br />

Installation details<br />

Location:<br />

Model:<br />

Area:<br />

Hyatt Regency Xi'an<br />

S10<br />

the water main of the Chinese kitchen<br />

Installed by: Hengsheng Chang Environmental<br />

Protection Technology Co., Ltd<br />

Installation purpose<br />

The results<br />

One month after the <strong>Vulcan</strong> S10 was installed, we<br />

opened the sewage outlet of the Chinese kitchen,<br />

and found that the scale scrap came out. At the<br />

same time, we compared the sewage outlet of the<br />

western kitchen without <strong>Vulcan</strong>, there is no scale<br />

coming out. The hotel manager is very satisfied<br />

with the results and is making a new purchase.<br />

The two steamers in the Chinese kitchen had been<br />

scaled badly, they had been corroded and damaged<br />

in 2 years. The client used to clean with acid once a<br />

month, but the steamed food had the taste of citric<br />

acid, and the acid would even damage the equipment.<br />

Therefore, the client is looking for an efficient way to<br />

remove the scale without bad odour after cleaning.<br />

<strong>Vulcan</strong> S10 was installed on the main water line of the<br />

Chinese kitchen.<br />

The scale scrap came out of the steamer in the Chinese<br />

kitchen.<br />

www.ky-xian.cn

16<br />

Ibis Surabaya City Center Hotel<br />

Indonesia<br />

ibis Surabaya City Center Hotel<br />

Economy hotel for business and leisure<br />

The 224 modern and minimalist rooms feature the<br />

new ibis bedding, 4 modern High Tech meeting<br />

rooms, a lobby bar and restaurant. Perfect for<br />

business and leisure travelers.<br />

Installation details<br />

Location:<br />

Model:<br />

Area:<br />

Installer:<br />

IBIS Hotel Surabaya<br />

Indonesia<br />

S25<br />

water main<br />

PT Biosolutions<br />

www.biosolutions.co.id<br />

<strong>Vulcan</strong> effect — before and after<br />

Before installing the <strong>Vulcan</strong> system, the pipeline had<br />

a lot of sedimentation of scale, the client had to do<br />

manual cleaning.<br />

After 3 months of <strong>Vulcan</strong>, it has begun to erode and<br />

clean the scale out of the system.<br />

The clients are happy with the performance of <strong>Vulcan</strong>.<br />

Hot Water Tank<br />

<strong>Vulcan</strong> S25 was installed on the main water pipe.<br />

Hotel Water <strong>System</strong><br />

Before<br />

After 3 months<br />

After 3 months scale is no longer forming and the hot<br />

water tank is free of scale and sediment.<br />

Hot Water Pipe<br />

Before<br />

After 3 months<br />

After 3 months the rust in the pipe has lightened and<br />

the amount of scale is gradually reducing.

17<br />

Ibis Budget Makassar Airport<br />

Indonesia<br />

ibis Budget - Makassar Airport<br />

Smart choice economy hotel, open to<br />

everyday adventurers<br />

Located in the heart of Sultan Hasanuddin Airport,<br />

it offers simple and functional new bedding of 119<br />

new cocoon rooms.<br />

Installation Details<br />

Location:<br />

Model:<br />

Area:<br />

Installer:<br />

Ibis Budget - Makassar Airport<br />

Indonesia<br />

S25<br />

Guest rooms ― bathroom water<br />

heating elements<br />

PT Biosolutions<br />

www.biosolutions.co.id<br />

"Before" <strong>Vulcan</strong> Installation<br />

Several rooms were monitored before <strong>Vulcan</strong> was<br />

installed and had large amounts of scale chunks on<br />

the heating element and at the reservoir sump (see<br />

pictures 2 & 3). <strong>Vulcan</strong> was installed at the main<br />

incoming water line to eliminate this problem (see<br />

picture 1).<br />

Picture 1. <strong>Vulcan</strong> installation process at the main<br />

incoming water line.<br />

Pictures 2 & 3. <strong>Scale</strong> previously coating the heating<br />

element and reservoir sump. (Picture taken from one<br />

of the rooms at IBMA hotel)<br />

"After" <strong>Vulcan</strong> Installation<br />

<strong>Scale</strong> gradually disappeared from the elements and<br />

reservoir sump. After 3 months scale is entirely gone<br />

from water heater elements and the reservoir sump.<br />

<strong>Vulcan</strong> has shown to successfully reduce time, energy<br />

and capital required by the hotel for water system<br />

maintenance. All pictures were taken from one out of<br />

ten rooms that were monitored before and after <strong>Vulcan</strong><br />

was installed, and all rooms’ water heater elements<br />

were also found to be free of scale.<br />

Pictures 4 & 5. Three weeks after <strong>Vulcan</strong> installation,<br />

initial scale has been eliminated.<br />

Pictures 6 & 7. Twelve weeks after <strong>Vulcan</strong> installation,<br />

no scale at all.

18<br />

Hotel Acacia Manila<br />

Philippines<br />

Tien Phong<br />

Technologies<br />

Acacia Hotel, Manila, Philippines<br />

The Acacia Hotel is a fi ve-star<br />

Hotel locating in Alabang, Manila.<br />

Acacia Hotel Manila exhibits<br />

the excellence of a homegrown<br />

brand that is deeply rooted in<br />

passion, excellence, and service.<br />

The hotel prides itself in creating<br />

an atmosphere of hospitality and<br />

exemplary service.<br />

Like other hotels, they use chiller systems with cooling<br />

towers to provide cool air for whole hotel. And with<br />

hard water, they have problems with scale in the heat<br />

exchanger and they have used chemicals to solve.<br />

With a desire to replace chemicals, they are looking<br />

for physical water treatments and fi nd <strong>Vulcan</strong>. After<br />

installing <strong>Vulcan</strong> S500 unit, their heat exchanger<br />

always stays clean without any chemicals.<br />

Here is the comment of the chief engineer: “The<br />

results are positive. We have recorded condenser<br />

approach value for 2 to 6 months after cleaning the<br />

tubes of the condenser, and there was a signifi cant<br />

decrease on our chillers’ condenser approaches. Our<br />

cooling towers remained clean and some of the stockup<br />

and passing valves are now usable. As regards<br />

the performance of the unit, we found it works well.”<br />

Model: <strong>Vulcan</strong> S500<br />

Installation Location:<br />

Main water supply of the cooling tower<br />

Purpose:<br />

• Clean scale deposit<br />

• Prevent scale<br />

• Reduce maintenance costs<br />

• Replace chemical treatment and softener systems<br />

Before <strong>Vulcan</strong> installation:<br />

• <strong>Scale</strong> deposits in the heat exchanger<br />

• Pipes clog<br />

After <strong>Vulcan</strong> installation:<br />

• Chiller and cooling tower stay clean<br />

• No need to use chemicals<br />

<strong>Vulcan</strong> S500 on cooling tower water pipe<br />

Chiller #3 Condenser<br />

Ø 67 cm, tube Ø 7/8“, length: 418 cm inside the tube inside the tube<br />

Tien Phong Technologies Co., Ltd<br />

No. 30, Street 12, Binh Hung Hoa ward, Binh Tan District, HCM City, Viet Nam Web: tpcorp.com.vn Email: sale@tpcorp.com.vn

19<br />

Palm Beach Hotel<br />

Tunisia<br />

Installation Details<br />

Palm Beach Club Hammamet<br />

Location:<br />

Model:<br />

Purpose:<br />

Installer:<br />

Palm Beach Hotel Hammamet, Tunisia<br />

<strong>Vulcan</strong> S25<br />

1. To protect the hot water circuit, the kitchen and the Spa<br />

2. To use an eco-friendly solution, without chemicals<br />

3. To reduce the workload of cleaning the pipes with high<br />

pressure water gun<br />

STPE+<br />

The hotel is located on one of the<br />

most beautiful beaches of the Gulf of<br />

Hammamet, in a magnificent 5 acres<br />

garden.<br />

All rooms have sea, garden or pool views<br />

with terrace or balcony.<br />

After <strong>Vulcan</strong> S25 had been installed<br />

for 6 months, the boiler was opened:<br />

scale had been softer and left out.<br />

The scale deposits were easily removed<br />

with a water gun.<br />

The scale deposits were drained out of<br />

the boiler with ZERO chemical.<br />

STPE+ SOCIETE DE TRAITEM<strong>EN</strong>T | Route GP1 Manaret de Hammamet, 8050 Hammamet, Tunisie | www.vulcan-tunisie.com

20<br />

Barcelo Bavaro Palace<br />

Dominican Republic<br />

The 5-star Barceló Bávaro Palace hotel is one of the top luxury hotels in Punta Cana, designed specifically for people who<br />

love constant sunshine, the gentle sound of the Caribbean breeze whispering in the palm trees, and beautiful crystal-clear<br />

waters with a coral reef. The hotel is beside one of the 10 most stunning beaches in the world.<br />

Installation details<br />

Location: Barceló Bávaro Palace<br />

La Antagracia, Dominican Republic<br />

www.barcelo.com<br />

Models: 2 x S100 in hotel’s main hot water lines<br />

3 x S250 for cooling towers<br />

4 x S500 for cooling towers<br />

Installed by: InterClima<br />

Installation purpose<br />

Most of the hotels in the area of Bávaro/Punta Cana in<br />

eastern Dominican Republic depend on ground water wells<br />

for their domestic water supply, using traditional water<br />

softening equipment to reduce the scale and hardness of<br />

the water. The fact is that some of these resorts have very<br />

poor maintenance resulting in extensive scaling of cooling<br />

towers and domestic hot water piping and equipment.<br />

The results<br />

The project began with a mechanical room energy<br />

audit resulting in a great opportunity to upgrade the<br />

existing equipment with a very short payback period.<br />

The original installation was sold with an estimated<br />

payback of less than 2 years. To our customer’s happy<br />

surprise, the actual payback was 9 months! The hotel<br />

maintenance manager is very impressed with the<br />

performance of the <strong>Vulcan</strong> systems, this opened up<br />

many additional opportunities including the subsequent<br />

chiller and cooling tower replacements.<br />

Before <strong>Vulcan</strong> S100 was installed in hotel’s main hot<br />

water line, the storage tanks had a solid 3 cm thick<br />

scale layer inside them and the pumping pressure from<br />

the booster set was at maximum while being unable to<br />

deliver adequate water pressure to the end of the line<br />

hotel rooms. After the 3 months period, an inspection<br />

of the inside of the storage tanks revealed that the<br />

scale layer was soft allowing them to mechanically<br />

clean them removing most of the calcium deposits.<br />

Other the following 12 to 18 months, the distribution<br />

lines also cleared up resulting in much improved flow<br />

and lower pumping costs from the booster sets.<br />

The manager was instrumental in the approval of the<br />

resent trial installation of an S250 in the Royalton White<br />

Sands (Jamaica). We will continue to use the Barceló<br />

success in our future presentations.<br />

3 chillers were treated by 3 <strong>Vulcan</strong> S500 Aerial view of Barceló Bávaro Palace next to the Bavaro beach, Higuey<br />

Interclima Corp. | 5805 Blue Lagoon Drive, Suite 175, Miami, FL 33126 | 305-260-0229 | www.inter-clima.com

21<br />

Lhasa 21 Inn<br />

China<br />

Lhasa 21 Inn<br />

Installation details<br />

Location: Lhasa 21 Inn, Tibet<br />

Model: <strong>Vulcan</strong> 5000<br />

The results<br />

1. After installing <strong>Vulcan</strong> 5000 for 1 month, the scales of the<br />

shower heads have been significantly reduced.<br />

Area:<br />

Installed by:<br />

Water main<br />

Shaanxi Wasser<br />

Installation Purpose<br />

In April 2017, a 6-ton tubular solar water heating system<br />

was installed. Without any water treatment, as of May 2018,<br />

due to the serious scaling problems, manual descaling and<br />

system maintenance had been made for 3 times. Even solar<br />

glass tubes, headers, valves, pumps, etc. must be replaced,<br />

the client had a large loss.<br />

Before<br />

After<br />

2. The scales on the float valve in the hot water tank have<br />

been softened, they can easily be tapped off.<br />

See the video here: www.bit.ly/cn-tank<br />

Before<br />

After<br />

Pipe joint fittings had to be replaced because of scale and rust.<br />

3. After 3 months of installation, we cleaned the hot water<br />

tank, and found a large amount of scales were drained out.<br />

The photo below is the scales removed from the water tank.<br />

Also, the heat transfer efficiency of the solar system has been<br />

significantly improved, the performance almost has stayed<br />

the same just like the beginning of installing <strong>Vulcan</strong>.<br />

安 装 在 中 式 厨 房 总 管 的 <strong>Vulcan</strong> S10<br />

Heating rods were damaged by scale.<br />

<strong>Scale</strong> removed from the water tank,<br />

after installing V5000 for 3 months.<br />

www.sauber-wasser.com<br />

EXCLUSIVE PARTNER

22<br />

Furama Hotel Dalian<br />

China<br />

Furama Hotel Dalian<br />

A luxurious five-star hotel with a long<br />

history in northeast China, the 30-storey<br />

building has a total of 620 rooms.<br />

Installation details<br />

Location:<br />

Model/Area:<br />

Furama Hotel Dalian<br />

www.furamahoteldalian.com<br />

<strong>Vulcan</strong> S25 installed on the inlet pipe of the hot<br />

water volumetric heat exchanger on the 31st floor of<br />

the West Building to solve the scale problem on the<br />

12th to 25th floors.<br />

<strong>Scale</strong> problems: Rusty water from the hot water pipes for bathing,<br />

scale build-up on the surface of of the shower<br />

heads in the guest room, scaling of fins in heat<br />

exchangers.<br />

Installer:<br />

Dalian Jiayifang<br />

www.vulcan-jiayifang.com<br />

<strong>Vulcan</strong> S25 installed on DN80<br />

copper pipe.<br />

Visible results after 10 months – before and after<br />

heating elements in the heat exchanger<br />

Heating elements in the heat exchanger<br />

Shower heads<br />

Before<br />

Before<br />

Before<br />

The hard scale between the fins affected the heat transfer efficiency and<br />

rusting caused problems with rusty water.<br />

After using shower heads, a layer<br />

of scale would build up on the<br />

surface, giving it a dirty look.<br />

After After After<br />

The fins were not cleaned before installing the <strong>Vulcan</strong> S25. 10 months later, the<br />

hard scale between the fins was removed and some areas were clean and even<br />

revealed the original colour of the copper tube. <strong>Vulcan</strong> has improved the water<br />

quality and saved energy and manual cleaning costs.<br />

No more scale build-up on the<br />

surface of the shower heads,<br />

and the water outlet is no longer<br />

blocked, which saves the cost of<br />

replacing and cleaning nozzle.

23<br />

Royalton Splash Punta Cana<br />

Dominican Republic<br />

RESORTS ACCOMMODATIONS RESTAURANTS & BARS<br />

Location:<br />

Memories Splash Punta Cana<br />

Punta Cana, Dominican Republic<br />

Models installed:<br />

2 x <strong>Vulcan</strong> S500<br />

1 x <strong>Vulcan</strong> S100<br />

Installed by:<br />

InterClima<br />

Application:<br />

The Royalton Punta Cana Resort & Casino is a 1000<br />

room resort located on the beachfront in Punta Cana,<br />

Dominican Republic.<br />

Two <strong>Vulcan</strong> S500 were intalled on the main input<br />

pipe in order to combat scale build up and increase<br />

efficiency of the three cooling towers.<br />

A <strong>Vulcan</strong> S100 is also installed on the resorts main<br />

hot water system, in order to remove and prevent<br />

scale build up in the heaters/boilers, which provide<br />

hot water throughout the entire entire resort and<br />

casino.<br />

<strong>Vulcan</strong> S500 protective casing<br />

<strong>Vulcan</strong> S500 cable windings<br />

www.grandparadisebavaro.com

24<br />

Hotel Meridien N׳Fis<br />

Morocco<br />

Hotel Méridien N'fis<br />

Avenue Mohamed VI,<br />

Marrakesh 40000,<br />

Morocco<br />

www.lemeridien.com<br />

Certificate of reference for the <strong>Vulcan</strong> Descaler<br />

In order to remove and prevent scale and rust<br />

issues affecting our pool areas and various<br />

hydraulic installations, we have purchased<br />

and installed the <strong>Vulcan</strong> S25 unit from CWT<br />

International.<br />

After receiving a very satisfactory result from<br />

the <strong>Vulcan</strong> S25, we plan to entrust the <strong>Vulcan</strong><br />

Descaler range with any future scale or rust<br />

problems in the Le Meridien N‘fis.<br />

Hotel Méridien N'fis pool and spa area protected by <strong>Vulcan</strong> S25<br />

Kind Regards,<br />

A Moursil.<br />

Technical Director.

25<br />

Karnavati Club Hotel<br />

India<br />

Karnavati Club Hotel in Ahmedabad, India<br />

A prestigious name known among the most known<br />

clubs and recreational organizations of Ahmedabad<br />

is The Karnavati Club. The club, with an area of<br />

500,000 sq.feet is located on the Sarkhej-Gandhinagar<br />

Highway. The club was established in 1989. And today,<br />

it is an ultimate success in the arena of recreational<br />

clubs.<br />

Installed:<br />

1 x <strong>Vulcan</strong> S100 for swimming pool<br />

1 x <strong>Vulcan</strong> S100 for the utility<br />

Installed by:<br />

Agencies PVT Ltd<br />

Two <strong>Vulcan</strong> S100 were installed. Salt based softener is replaced by <strong>Vulcan</strong> S100.<br />

Karnavati Club Ltd.

26<br />

Holiday Resort Lombok<br />

Indonesia<br />

Reason for <strong>Vulcan</strong> installation<br />

Engineering had to manually remove scale from pumps,<br />

valves, kitchen equipment and from the 102 individual<br />

electric hot water heaters every 6 months because the<br />

property relies entirely on hard ground water which caused<br />

signifi cant scale issues year after year.<br />

Holiday Resort Lombok, Indonesia<br />

189 Bungalows / various types of guest rooms<br />

/ extensive landscaped gardens / 2 Swimming<br />

Pools / several Food and Beverage outlets<br />

www.holidayresort-lombok.com<br />

Result installation of <strong>Vulcan</strong> S25<br />

The Chief Engineer reported after an initial 6 months<br />

following installation of the electronic anti-scale system<br />

<strong>Vulcan</strong> S25 they were able to easily flush out already<br />

dislodged scale from each tank heating unit – instead of<br />

scraping away hard scale from the elements. After a second<br />

inspection the units were found to be almost entirely free of<br />

scale. Future inspections have now been reduced to annual,<br />

random inspections only – which is felt to be suffi cient to<br />

ensure overall domestic water piping system cleanliness.<br />

<strong>Anti</strong>-<strong>Scale</strong> <strong>System</strong> <strong>Vulcan</strong> S25 installed<br />

Inspection after 6 months<br />

One of the water heaters at a Sea View Bungalow (photo)<br />

was opened for inspection and showed much dislodged scale<br />

particles at the bottom of the tank, with some easily removed<br />

soft scale still present on the element only. This water heater<br />

unit had not been scheduled for random inspection since<br />

installation of the <strong>Vulcan</strong> unit at the Resort.<br />

Additional benefits reported<br />

The General Manager and CE reported that shortly after the<br />

<strong>Vulcan</strong> had been installed, the linen being washed at the<br />

inhouse Laundry plant was softer and whiter. In addition,<br />

Food and Beverage staff reported brighter glass ware<br />

with the detergents working much better. Housekeeping<br />

staff reported that the usual white spots on bathroom tubs,<br />

counters and floors had entirely disappeared and that outlets<br />

of showers and taps needed no longer special attention with<br />

only basic wiping being suffi cient to maintain their shine.<br />

The little remaining scale is soft and easily fl ushed<br />

out since installation of the <strong>Vulcan</strong> <strong>Anti</strong>-<strong>Scale</strong> <strong>System</strong>.<br />

Gd. Aldevco Annex Building Lt. 3 • Jl. Warung Jati Raya no. 75 • Jakarta Selatan • Indonesia • www.biosolutions.co.id<br />

EXCLUSIVE PARTNER

27<br />

Aura Hotel<br />

Hungary<br />

www.aura-hotel.hu<br />

INSTALLATION DETAILS<br />

Location:<br />

AURA HOTEL<br />

8320 Balatonfüred,<br />

Munkácsy M. u.5., Hungary<br />

www.aura-hotel.hu<br />

Model:<br />

<strong>Vulcan</strong> S50<br />

Area: Main water inlet pipe<br />

Installed by: VARÁZSMAG Kft<br />

PURPOSE<br />

General protection of the piping system.<br />

They had to maintain the ice-machines monthly,<br />

the faucets and shower heads were blocked by<br />

the scale after 6 months of opening the Hotel,<br />

the tiles and the shower walls were extremely<br />

scaly. They cleaned the bathrooms manually,<br />

that lasts for hours. The faucets had to be<br />

changed and the ice machine had to be repaired.<br />

RESULTS<br />

The faucets and tiles can be cleaned by wiping the<br />

powder-formed scale. The ice-machine working<br />

properly. The dishwasher gives out perfectly<br />

shiny and spotless dishes and glassware.<br />

“I really appreciate that<br />

all machines and equipment<br />

work properly<br />

again in the kitchen and<br />

I can focus on creating<br />

and serving the best<br />

meals to our guests.“<br />

Sándor Böröcz<br />

Head Chef<br />

EXCLUSIVE PARTNER<br />

VARÁZSMAG Kft | +36-30-703-3424 | Kelenhegyi út 46/D fszt.1., 1118 Budapest | www.cwt-vulcan.hu

Schools<br />

Educational Institutions<br />

Sporting Facilities

30<br />

FAMU / FSU (<strong>Vulcan</strong> Effects on Cooling Towers)<br />

Florida Agricultural Mechanical University / Florida State University<br />

USA<br />

<strong>Vulcan</strong> Effects on<br />

Cooling Towers<br />

Installation details<br />

Location:<br />

Area:<br />

Model:<br />

Objectives:<br />

Installed by:<br />

FAMU/FSU College of Engineering<br />

On the 10 inch diameter line that feeds twin cooling towers<br />

(CT-1 and CT-2)<br />

S25<br />

1. To prevent scale buildup on the cooling towers<br />

2. To remove the existing scale<br />

3. To eliminate the need for chemicals or time-consuming<br />

cleaning procedures<br />

4. To reduce energy costs<br />

Ackuritlabs, Inc.<br />

History<br />

The maintenance for these cooling towers previously involved continuous<br />

injection of descaling chemical cleansers. The use of these cleansers was<br />

discontinued over a year prior to the installation of the <strong>Vulcan</strong>. In that time, the<br />

cooling tower flutes became encrusted with both scale and biofilm. Throughout<br />

the time period described below, there were no cleaning procedures in place<br />

with these cooling towers besides the treatment provided by the <strong>Vulcan</strong>.<br />

Observations over time after the <strong>Vulcan</strong> installation<br />

<strong>Vulcan</strong> S250 installed on a 10 inch diameter line<br />

that feeds twin cooling towers (CT-1 and CT-2)<br />

After 2 weeks, the green biofilm had begun to recede and gradually disappear.<br />

After 3 weeks, the green biofilm had been further reduced and the scale<br />

deposits had begun to separate from the flutes in coin-sized flakes.<br />

After 1 month, the green biofilm had almost completely disappeared from<br />

the surfaces in contact with the <strong>Vulcan</strong>-treated water. The flakes of scale<br />

previously observed had fallen off in most places. The cooling tower flute<br />

surface area covered with scale deposits had been decreased by over 60%.<br />

The <strong>Vulcan</strong> does not change the water quality beyond its affect on its<br />

propensity to cause scale buildup. The pH, conductivity, dissolved oxygen level,<br />

and turbidity remained relatively constant during observation from before the<br />

installation to over a month after.<br />

We are very optimistic about continued improvement with <strong>Vulcan</strong>.<br />

The inside of CT-1, after 3 weeks with <strong>Vulcan</strong>.<br />

It illustrates clean flutes that are in constant contact<br />

with <strong>Vulcan</strong>-treated water and a few dry (untreated)<br />

areas that still have some remaining green biofilm.<br />

The photo above was taken of CT-1 about 3 weeks after the<br />

<strong>Vulcan</strong> was installed.<br />

The photo above was taken of CT-1 about 6 weeks<br />

after the <strong>Vulcan</strong> was installed.

31<br />

Spokane Public Schools Washington<br />

USA<br />

–––<br />

<strong>Vulcan</strong> installed in<br />

Spokane Public Schools<br />

Installation locations<br />

Dear CWT Team,<br />

Spokane schools now have 6 <strong>Vulcan</strong> units installed.<br />

One of the first <strong>Vulcan</strong> units is on a small cooling tower and this stays<br />

absolutely clean during the season. The tower was full of scale when we<br />

started and after 4 weeks, scale started to fall of in big chunks and now<br />

it is completely scale free.<br />

Roosevelt Elementary School<br />

333 West 14th Ave<br />

Spokane, WA 99204-3627<br />

USA<br />

Installation of <strong>Vulcan</strong> Descaler for the entire buildings water supply in the Roosevelt school<br />

Our first installation in Spokane schools was in Shaw Middle School,<br />

50 years old building and with rusty/dirty looking water.<br />

This was installed before the school started in the fall.<br />

After Christmas this year, the water is always clean and the janitor<br />

does not have to flush the piping anymore.<br />

Have a great day.<br />

Arne Vestad<br />

IWTNA<br />

Shaw Middle School<br />

4106 N. Cook St.<br />

Spokane, WA 99207<br />

USA

32<br />

Florida State University<br />

USA<br />

Florida State University<br />

600 W. College Avenue<br />

Tallahassee<br />

FL 32306<br />

Dear Ackuritlabs Team,<br />

Please fi nd below photos of the <strong>Vulcan</strong> Descaler installed in the Florida State University Biomedical Facility.<br />

These pictures are of a stainless steel rack washer and conveyer steam washer, after the <strong>Vulcan</strong> units were<br />

installed on the entire Biomedical Research Building.<br />

Regards,<br />

The Florida State Bio-medical Team<br />

<strong>Vulcan</strong> unit installed on water main<br />

Stainless steel rack washer now completely scale free<br />

Conveyer steam washer<br />

Installed by Ackuritlabs, Inc. 3345B North Monroe St Tallahassee, FL 32303

33<br />

Beijing University of Chemical Technology (Student Dormitory)<br />

China<br />

Beijing University of Chemical Technology<br />

Dear Christiani Wassertechnik GmbH (CWT),<br />

Due to the shower head scaling problem in Changping student dormitory in<br />

Beijing University of Chemical Technology, the water was getting reduced after a<br />

month, and the shower head was blocked completely after two to three months.<br />

The scale was very hard, so we even had to use the 1.8mm driller to remove<br />

it. In addition, the drinking water heater in the student dormitory was scaled<br />

badly, two heating elements were completely scaled and no longer useful after<br />

one semester, we had to hire cleaning workers regularly, and the damage rate of<br />

heating elements was extremely high.<br />

When I saw <strong>Vulcan</strong> products introduced by your distributor-Beijing North Xinhu<br />

Mechatronics Co., Ltd, we doubted if such a simple product could solve our scaling<br />

problem. Let's try and see.<br />

We installed 2 <strong>Vulcan</strong> to test: one S25 for shower heads in the student bathroom;<br />

one S10 for heating elements of drinking water. After 2 months, no scale was<br />

found on the shower heads, only saw a thin layer of white membrane, and it was<br />

easy to remove. Also, the scale of heating elements were significantly reduced,<br />

<strong>Vulcan</strong> greatly extends the time of manual cleaning.<br />

Through this test, we are very satisfied with <strong>Vulcan</strong> products with no doubts.<br />

Strongly recommended!<br />

Kind regards,<br />

Repair Service Center<br />

Beijing University of<br />

Chemical Technology<br />

<strong>Vulcan</strong> S25 for solving the shower<br />

head scaling problem.<br />

The student dormitory of<br />

Beijing University of Chemical<br />

Technology.<br />

After installing <strong>Vulcan</strong> for 2<br />

months, the scale of shower<br />

head has been reduced.

34<br />

Prince Sattam bin Abdulaziz University<br />

Saudi Arabia<br />

Installation details<br />

Step 1<br />

Model:<br />

Location:<br />

<strong>Vulcan</strong> S250<br />

Prince Sattam bin Abdulaziz University<br />

Al Kharj, Saudi Arabia<br />

www.psau.edu.sa<br />

►<br />

Installed by: Wrood Al Shame for Trading &<br />

Contracting Est.<br />

Step 2<br />

First, wind plastic foil around the pipe to protect the impulse<br />

bands against condensation on the pipe.<br />

Step 3<br />

►<br />

►<br />

Wrap the impulse bands around the plastic foil.<br />

Connect the <strong>Vulcan</strong> S250 unit with the impulse bands.<br />

(<strong>Vulcan</strong> unit was installed in the outdoor case to prevent<br />

from humidity.)<br />

Step 4<br />

Step 5<br />

►<br />

Check the functionality of <strong>Vulcan</strong> with a impulse detector.<br />

To finish, install an insulation protection to cover the<br />

impulse bands completely against the elements.<br />

Wrood Al Shame for Trading & Contracting Est. | Sabbagh.co@hotmail.com<br />

Babten Building, Beside Al Riyadh Bank, Takasusi St. Riyadh City, 11553 Riyadh, Kingdom of Saudi Arabia

35<br />

Irrigation for a Football Field<br />

Saudi Arabia<br />

Irrigation water for the natural grass football fields<br />

Dear Mr. Christiani,<br />

<strong>Reference</strong> to the above mentioned subject, we have installed VULCAN S100. After a year,<br />

the result on irrigation water for the natural grass football fields was very satisfactory.<br />

The company which is behind the maintenance of football fields feeling well, they have sent<br />

reports to the Saudi Government Sports Ministry they wrote on their reports that there's<br />

good result on using this devices.<br />

For your information and references.<br />

Engr. Ziad Sabbagh

36<br />

Hartwall Ice Hockey Arena<br />

Finland<br />

f,fARTWALl<br />

A R E E N A<br />

HARTWALL ARE<strong>EN</strong>A<br />

Helsinki Halli Oy<br />

Areenakuja J. FIN--00240 Helsinki<br />

Tel. +358 (0)204 1997, Fax +358 (0)204 1994<br />

Internet: http://www.hartwall-areena.com<br />

Hartwall - Areena<br />

Areenankuja 1<br />

FI-00240 Helsinki,<br />

Finland<br />

CWT-Christiani Wassertechnik GmbH<br />

Herr Rolf Christiani<br />

Köpenicker Str. 154<br />

10997 Berlin<br />

Dear Sir<br />

We have been using CWT-Christiani Wassertechnik Gmbh<strong>Vulcan</strong><br />

water treatment equipment in our ice hockey hall Hartwall Arena.<br />

We are using many sizes of <strong>Vulcan</strong> for several heating/cooling<br />

equipment in our water system:<br />

<strong>Vulcan</strong> 5000<br />

<strong>Vulcan</strong> S 25<br />

- <strong>Vulcan</strong> S 100.<br />

We have realibility with these systems and have been most satisfied<br />

in using them.<br />

<strong>Vulcan</strong> is a high-quality and great solution to different kind of<br />

premises.<br />

Yours sincerely,<br />

Hartwall - Areena<br />

/-<br />

;>ariVäananen

37<br />

Powerhouse Gym<br />

USA<br />

Installation Details<br />

Location: Powerhouse Gym, Michigan, USA<br />

www.powerhousegym.com<br />

Model: <strong>Vulcan</strong> S25<br />

Installer: Green Salt Free Water Solutions<br />

Powerhouse Gym<br />

The Powerhouse Gym name and brand has been one<br />

of the top leaders in the fitness industry for over 40<br />

years. With 300 licensees in 39 states, Powerhouse<br />

has continued to steadily gain global attention by<br />

expanding into 17 different countries worldwide. The<br />

first Powerhouse Gym still stands in its original location<br />

and celebrated its 40th anniversary in 2014.<br />

The Powerhouse Gym Trademark is associated with<br />

service and quality, and is apparent throughout each<br />

and every Powerhouse Gym that opens its doors to over<br />

1.2 million dedicated members. Step 1: Install the<br />

impulse bands<br />

Step 2: Install the S25 unit on<br />

the water main and wrap the<br />

protection layer<br />

Green Salt Free Water Solutions | 3596 W. Maple Rd. Ste 108, Bloomfield Hills, MI. 48301, USA | www.GreenSaltFreeWaterSolutions.com

38<br />

Ice Stadium Neuchâtel<br />

Switzerland<br />

INTERMUNICIPAL UNION<br />

Direction of Skating Rinks<br />

<strong>Vulcan</strong> S100<br />

Mister,<br />

<strong>Anti</strong>-scale <strong>Vulcan</strong><br />

W. Kurt<br />

4103 Bottmingen<br />

Following our discussions at the Salon de l‘immobilier Neuchâtelois, we agreed to install the <strong>Vulcan</strong><br />

model S100 on our premises for a five-month test phase as soon as our ice period began operating<br />

in August.<br />

The defined objective was mainly intended for the dumpsters of our two ice resurfacers, which are<br />

filled with snow all day long and therefore subject to weekly descaling.<br />

After a few weeks, we noticed that the scale adhered less. This makes it easier to clean our machines,<br />

saving us time and products.<br />

The test carried out allowed us to take the time to compare the positive effects of the <strong>Vulcan</strong> S100 on<br />

our installation and that the objective set was achieved.<br />

We would like to take this opportunity to thank you for your warm cooperation and extend our warmest<br />

greetings to you, Sir.<br />

Operations Manager<br />

Quai Robert-Comtesse 4 - 2000 Neuchâtel - Tél. 032 717 85 50 - Fax 032 717 85 47 - Email : patinoires.littoral.ne@ne.ch

Water treatment system by CWT Germany<br />

39<br />

Ice Land Stadium<br />

USA<br />

My wife and I live on a 5 acre property at Gelo<br />

Australia. Our local water causes enormous proble<br />

of iron sludge and chips would build up in the pipin<br />

sprinklers. The situation was getting us both down<br />

blocked and I was replacing the solenoids every si<br />

Within three months of installing the CWT water tre<br />

appeared. I was staggered by the results. The pip<br />

of the iron scale at all.<br />

A reliable and clean sprinkler system is very importan<br />

more than 200 rose bushes and half an acre of trees<br />

under reticulation. The CWT system has saved me a<br />

longer cleaning sprinkler heads or replacing the so<br />

Installation details<br />

The results have been so successful we ar<br />

garden and bird aviary. I would recommend this pr<br />

in Australia. They’re simple to install and maintena<br />

Model:<br />

Location:<br />

Installation area:<br />

Installed by:<br />

<strong>Vulcan</strong> S25<br />

Ice Land, New Jersey<br />

Treats water used for ice production<br />

Princeton Management Advisory and Consulting LLC<br />

Lance Butcher from Western Australian enjoying his clean sprinkler s<br />

<strong>Vulcan</strong> S25 installed at Ice Land, New Jersey<br />

25 Route 31 South, Suite PMB 2005, Pennington, NJ 08534 www.vulcan-descaler-new-jersey.com

Production<br />

and<br />

Industries

42<br />

Coca Cola<br />

Morocco<br />

Installation details<br />

Model: <strong>Vulcan</strong> 5000<br />

Location: Coca-Cola Factory<br />

Marrakech, Morocco<br />

Area: the water inlet of the water recycling room<br />

Pipe:<br />

2’’, stainless steel pipe<br />

After <strong>Vulcan</strong> installation:<br />

1. Two weeks after <strong>Vulcan</strong> was installed, lots of scale<br />

deposits had disappeared in the pipe.<br />

2. 48 hours after <strong>Vulcan</strong> was installed, the filter still<br />

stays clean.<br />

3. Less maintenance.<br />

The Coca-Cola factory in Marrakech, Morocco<br />

►<br />

Before <strong>Vulcan</strong> installation:<br />

the pipe was full of scale<br />