catalog 717.qxd

catalog 717.qxd

catalog 717.qxd

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Page 8<br />

CATALOG<br />

Refrigerant Distributors<br />

Direct Expansion – Steel & Aluminum<br />

Models – Flange Connections<br />

Sporlan refrigerant distributors for R-717 function like<br />

our conventional brass models.<br />

Steel models – The distributor body is Type 8620 vacuum<br />

degassed steel. The nozzle is Type 303 stainless steel,<br />

and the dispersion cone in the distributor is made of<br />

Stellite.<br />

Distributor tube connections are available for 3/16", 1/4",<br />

and 5/16" OD steel tubing. The ODF connections are<br />

trepanned to facilitate welding the joint. A 1/8" NPT connection<br />

is also available with Types 1130, 1133, and 1138<br />

distributors.<br />

Aluminum models – These distributors are designed for<br />

R-717 aluminum coils, and they are 6061-T6 aluminum.<br />

As with the steel distributors, the dispersion cone is<br />

Stellite, and the nozzle is stainless steel.<br />

Distributor tube connections are available for 3/16", 1/4",<br />

and 5/16" OD aluminum tubing. Aluminum brazing techniques<br />

require more space between circuits than copper<br />

to brass brazing. As a result, the maximum number of<br />

circuits is less than for comparable brass models.<br />

Applying Distributors to Thermostatic<br />

Expansion Valves<br />

All Type D and Type A TEVs up to and including 50 tons,<br />

employ a discharge tube. The discharge tube reduces<br />

refrigerant velocity across the valve port, preventing premature<br />

pin and seat erosion. When a distributor is used<br />

with these valves, the distributor nozzle performs the discharge<br />

tube’s function. The discharge tube must then be<br />

removed from the valve to avoid excessive pressure drop.<br />

Distributor performance is best obtained if the distributor<br />

is bolted directly to the TEV outlet. When it is not<br />

possible to bolt the TEV to the distributor, or if a shut off<br />

valve is installed between them, use a short, straight<br />

piece of pipe to connect the two. The pipe should not<br />

exceed two feet. It should be sized to maintain high<br />

refrigerant velocities. Elbows between the TEV and distributor<br />

are not recommended since they hinder proper<br />

distribution.<br />

Ratings for Refrigerant 717 Distributors<br />

Full load ratings are based on 30 psi nozzle, 10 psi tube pressure<br />

drop and 86° liquid temperature entering thermostatic<br />

expansion valve.<br />

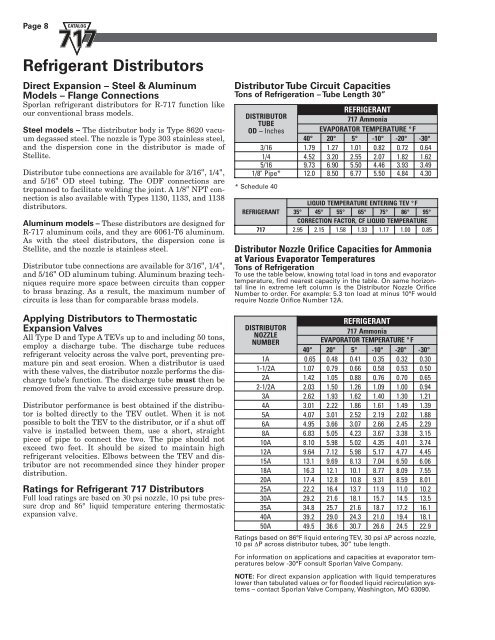

Distributor Tube Circuit Capacities<br />

Tons of Refrigeration – Tube Length 30”<br />

REFRIGERANT<br />

DISTRIBUTOR<br />

717 Ammonia<br />

T UBE<br />

OD<br />

– Inches<br />

EVAPORATOR<br />

TEMPERATURE ° F<br />

40°<br />

20°<br />

5 ° - 10°<br />

- 20°<br />

-30°<br />

3/16<br />

1.79<br />

1.27<br />

1.01<br />

0.82<br />

0.72<br />

0.64<br />

1/4<br />

4.52<br />

3.20<br />

2.55<br />

2.07<br />

1.82<br />

1.62<br />

5/16<br />

9.73<br />

6.90<br />

5.50<br />

4.46<br />

3.93<br />

3.49<br />

1/8"<br />

Pipe* 12.<br />

0 8.50<br />

6.77<br />

5.50<br />

4.84<br />

4.30<br />

* Schedule 40<br />

LIQUID TEMPERATURE ENTERING TEV ° F<br />

REFRIGERANT 35°<br />

45°<br />

55°<br />

65°<br />

75°<br />

86°<br />

95°<br />

CORRECTION FACTOR, CF LIQUID TEMPERATURE<br />

717<br />

2.95<br />

2.15<br />

1.58<br />

1.33<br />

1.17<br />

1.00<br />

0.85<br />

Distributor Nozzle Orifice Capacities for Ammonia<br />

at Various Evaporator Temperatures<br />

Tons of Refrigeration<br />

To use the table below, knowing total load in tons and evaporator<br />

temperature, find nearest capacity in the table. On same horizontal<br />

line in extreme left column is the Distributor Nozzle Orifice<br />

Number to order. For example: 5.3 ton load at minus 10°F would<br />

require Nozzle Orifice Number 12A.<br />

REFRIGERANT<br />

DISTRIBUTOR<br />

717 Ammonia<br />

NOZZLE<br />

NUMBER<br />

EVAPORATOR TEMPERATURE ° F<br />

40°<br />

20°<br />

5 ° - 10°<br />

- 20°<br />

-30°<br />

1A<br />

0.65<br />

0.48<br />

0.41<br />

0.35<br />

0.32<br />

0.30<br />

1-1/2A<br />

1.07<br />

0.79<br />

0.66<br />

0.58<br />

0.53<br />

0.50<br />

2A<br />

1.42<br />

1.05<br />

0.88<br />

0.76<br />

0.70<br />

0.65<br />

2-1/2A<br />

2.03<br />

1.50<br />

1.26<br />

1.09<br />

1.00<br />

0.94<br />

3A<br />

2.62<br />

1.93<br />

1.62<br />

1.40<br />

1.30<br />

1.21<br />

4A<br />

3.01<br />

2.22<br />

1.86<br />

1.61<br />

1.49<br />

1.39<br />

5A<br />

4.07<br />

3.01<br />

2.52<br />

2.19<br />

2.02<br />

1.88<br />

6A<br />

4.95<br />

3.66<br />

3.07<br />

2.66<br />

2.45<br />

2.29<br />

8A<br />

6.83<br />

5.05<br />

4.23<br />

3.67<br />

3.38<br />

3.15<br />

10A<br />

8.10<br />

5.98<br />

5.02<br />

4.35<br />

4.01<br />

3.74<br />

12A<br />

9.64<br />

7.12<br />

5.98<br />

5.17<br />

4.77<br />

4.45<br />

15A<br />

13.<br />

1 9.69<br />

8.13<br />

7.04<br />

6.50<br />

6.06<br />

18A<br />

16.<br />

3 12.<br />

1 10.<br />

1 8.77<br />

8.09<br />

7.55<br />

20A<br />

17.<br />

4 12.<br />

8 10.<br />

8 9.31<br />

8.59<br />

8.01<br />

25A<br />

22.<br />

2 16.<br />

4 13.<br />

7 11.<br />

9 11.<br />

0 10. 2<br />

30A<br />

29.<br />

2 21.<br />

6 18.<br />

1 15.<br />

7 14.<br />

5 13. 5<br />

35A<br />

34.<br />

8 25.<br />

7 21.<br />

6 18.<br />

7 17.<br />

2 16. 1<br />

40A<br />

39.<br />

2 29.<br />

0 24.<br />

3 21.<br />

0 19.<br />

4 18. 1<br />

50A<br />

49.<br />

5 36.<br />

6 30.<br />

7 26.<br />

6 24.<br />

5 22. 9<br />

Ratings based on 86°F liquid entering TEV, 30 psi ∆P across nozzle,<br />

10 psi ∆P across distributor tubes, 30” tube length.<br />

For information on applications and capacities at evaporator temperatures<br />

below -30°F consult Sporlan Valve Company.<br />

NOTE: For direct expansion application with liquid temperatures<br />

lower than tabulated values or for flooded liquid recirculation systems<br />

– contact Sporlan Valve Company, Washington, MO 63090.