- Page 1 and 2:

Drop Impact on Dry Surfaces with Ph

- Page 3 and 4:

Hiermit versichere ich, die vorlieg

- Page 5 and 6:

Fachgebiet Reaktive Strömungslehre

- Page 7 and 8:

to non-monotonic threshold impact v

- Page 9 and 10:

Splash, einseitiger Splash sowie de

- Page 11 and 12:

3.4.2. Calibration of the Infrared

- Page 14 and 15:

Nomenclature Latin capitals Unit A

- Page 16 and 17:

k angular wavenumber rad m −1 k R

- Page 18 and 19:

F G ge i K L lam m max min n opt r

- Page 20 and 21:

1 Introduction 1.1 Motivation Aircr

- Page 22 and 23:

of the WCE acquired experimentally

- Page 24:

passage was cooled down to −196

- Page 27 and 28:

SLD icing conditions have been defi

- Page 29 and 30:

−9 ◦ C and layers of freezing r

- Page 31 and 32:

adjacent downstream control volume,

- Page 33 and 34:

conventional methods. Papadakis et

- Page 35 and 36:

Figure 2.5.: Ice horn and clear ice

- Page 37 and 38:

This model showed good agreement un

- Page 39 and 40: Xu et al. proposed the following sc

- Page 41 and 42: Figure 2.9.: Splash thresholds of t

- Page 43 and 44: Chen and Wang [28] observed the dro

- Page 45 and 46: 2.14 shows. On stainless steel, tin

- Page 47 and 48: years ago [157]. Another peculiarit

- Page 49 and 50: Figure 2.17.: At an ambient pressur

- Page 51 and 52: The temperature needs to be found o

- Page 53 and 54: The Stefan number St S completely c

- Page 55 and 56: T(x, 0) = T A < T m , 0 < x < ∞ b

- Page 57 and 58: Figure 2.20: Fraction of solidifica

- Page 59 and 60: The mathematical description of the

- Page 61 and 62: asal plane. Without all these facto

- Page 64: Part I. Impact of Supercooled Water

- Page 68 and 69: 3 Experimental Setup This chapter i

- Page 70 and 71: drop and the tube as between such t

- Page 72 and 73: of nucleation ice dendrite growth,

- Page 74 and 75: The boundary condition is then 1

- Page 76 and 77: 0.021 W m −1 K −1 at −165 ◦

- Page 78 and 79: outlet of the liquid. There are two

- Page 80 and 81: The maximum depth of water in the c

- Page 82 and 83: Figure 3.11.: Pneumatic drop genera

- Page 84 and 85: Figure 3.13.: Pneumatic drop genera

- Page 86 and 87: Adjusting the Pulse Width Longer el

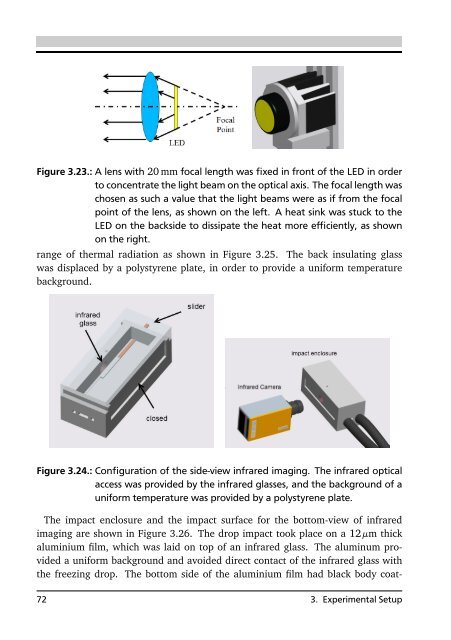

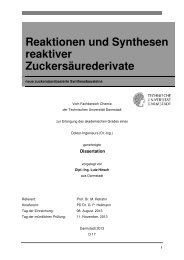

- Page 88 and 89: (a) Shadowgraph imaging (b) The sid

- Page 92 and 93: Figure 3.25.: The transmittance of

- Page 94 and 95: eproducible. The SHS was created by

- Page 96 and 97: Figure 3.30.: Planck’s law The ot

- Page 98 and 99: Figure 3.32.: Heterogeneity of the

- Page 100 and 101: Figure 3.35.: The valid region afte

- Page 102 and 103: Divided by dΩ, Eq. 3.33 is related

- Page 104 and 105: Figure 3.39.: The wavelength depend

- Page 106 and 107: Figure 3.41.: Orientation dependenc

- Page 108 and 109: wavelength, so that the value for r

- Page 110 and 111: Temperature Gradient In light of th

- Page 112 and 113: (a) 0.00 ms (b) 1.39 ms (c) 2.79 ms

- Page 114 and 115: Figure 3.48.: Synchronization syste

- Page 116: Figure 3.50.: Experimental setup fo

- Page 119 and 120: (a) 0 ms (b) 0 ms (c) 0.6 ms (d) 0.

- Page 121 and 122: Figure 4.2.: The dynamic spreading

- Page 123 and 124: Figure 4.4.: Influence envelope of

- Page 125 and 126: (a) 0 ms (b) 0.4 ms (c) 0.8 ms (d)

- Page 127 and 128: (a) 0 ms (b) 1.39 ms (c) 2.79 ms (d

- Page 129 and 130: (a) 0 ms (b) 0.05 ms (c) 0.1 ms (d)

- Page 131 and 132: (a) −4 ◦ C, at 6.8 ms. (b) −1

- Page 133 and 134: The contact temperature is closer t

- Page 135 and 136: Obviously, the contact temperature

- Page 137 and 138: Figure 4.13.: The dimensionless min

- Page 139 and 140: always after the receding reached t

- Page 142:

Part II reports the experimental in

- Page 145 and 146:

to realize a high-speed rotation of

- Page 147 and 148:

Figure 5.2.: Impact surface with di

- Page 149 and 150:

Various such devices were developed

- Page 151 and 152:

than the values reported in literat

- Page 153 and 154:

Figure 5.7.: The monodisperse drop

- Page 155 and 156:

This performance is a reminiscence

- Page 157 and 158:

Figure 5.11.: The merging distance

- Page 159 and 160:

signal and the excitation signal of

- Page 161 and 162:

The analogy with a capacitor led to

- Page 163 and 164:

The real situation in the applicati

- Page 165 and 166:

Figure 5.15.: Static electric field

- Page 167 and 168:

Figure 5.19.: Phase shift and pulse

- Page 169 and 170:

disadvantage is that the number of

- Page 171 and 172:

Zoom Lens Working Distance Spatial

- Page 173 and 174:

the impact surface was not a sharp

- Page 175 and 176:

5.5 Synchronization Both single pul

- Page 177 and 178:

The last note on these two pulse tr

- Page 179 and 180:

Figure 5.28.: Calculation of the im

- Page 182 and 183:

6 Results and Discussion This chapt

- Page 184 and 185:

(a) 0 µs (b) 2 µs (c) 4 µs (d) 6

- Page 186 and 187:

high impact velocities approaching

- Page 188 and 189:

(a) 32 µs (b) 84 µs (c) 100 µs F

- Page 190 and 191:

(a) (b) (c) Figure 6.8.: Examinatio

- Page 192 and 193:

Our observations show that the lame

- Page 194 and 195:

6.3 Velocity of the Uprising Jet In

- Page 196 and 197:

(a) 1 µs (b) 3 µs (c) 4 µs Figur

- Page 198 and 199:

(a) 0 µs (b) 8 µs (c) 32 µs Figu

- Page 200 and 201:

(a) 45° target (b) 75° target (c)

- Page 202 and 203:

Nevertheless, the drop volume was e

- Page 204:

was surface tension. These factors

- Page 207 and 208:

the motion of the impinging water,

- Page 209 and 210:

of the single-side splash, the latt

- Page 211 and 212:

(a) 0 µs (b) 2 µs (c) 4 µs (d) 6

- Page 213 and 214:

(a) 0 µs (b) 1 µs (c) 2 µs (d) 3

- Page 215 and 216:

(a) 0 µs (b) 3 µs (c) 6 µs (d) 9

- Page 217 and 218:

(a) 0 µs (b) 10 µs (c) 11 µs (d)

- Page 219 and 220:

(a) 0 µs (b) 3 µs (c) 5 µs (d) 8

- Page 221 and 222:

(a) 0 µs (b) 1 µs (c) 2 µs (d) 3

- Page 223 and 224:

(a) 0 µs (b) 6 µs (c) 10 µs (d)

- Page 225 and 226:

(a) 0 µs (b) 1 µs (c) 3 µs (d) 5

- Page 227 and 228:

(a) 0 µs (b) 8 µs (c) 24 µs (d)

- Page 229 and 230:

(a) 0 µs (b) 2 µs (c) 5 µs (d) 8

- Page 231 and 232:

(a) 0 µs (b) 16 µs (c) 32 µs (d)

- Page 233 and 234:

(a) 0 µs (b) 8 µs (c) 20 µs (d)

- Page 235 and 236:

A.7 5° target (a) 0 µs (b) 24 µs

- Page 237 and 238:

(a) 0 µs (b) 20 µs (c) 36 µs (d)

- Page 239 and 240:

(a) 0 µs (b) 8 µs (c) 16 µs (d)

- Page 241 and 242:

(a) 0 µs (b) 24 µs (c) 52 µs (d)

- Page 243 and 244:

(a) 0 µs (b) 16 µs (c) 32 µs (d)

- Page 245 and 246:

(a) 0 µs (b) 20 µs (c) 40 µs (d)

- Page 247 and 248:

(a) 0 µs (b) 10 µs (c) 22 µs (d)

- Page 249 and 250:

(a) 0 µs (b) 36 µs (c) 68 µs (d)

- Page 251 and 252:

(a) 0 µs (b) 36 µs (c) 72 µs (d)

- Page 253 and 254:

(a) 0 µs (b) 8 µs (c) 16 µs (d)

- Page 255 and 256:

(a) (b) (c) (d) (e) (f) Figure B.4.

- Page 257 and 258:

(a) 0 ms (b) 0.4 ms (c) 0.5 ms (d)

- Page 259 and 260:

(a) 0 ms (b) 0.35 ms (c) 1 ms (d) 1

- Page 261 and 262:

2.15.Prompt splash (left) was docum

- Page 263 and 264:

3.12.Time t =0 corresponds to the s

- Page 265 and 266:

3.31.The extension ring (left) betw

- Page 267 and 268:

4.7. Infrared imaging: total reboun

- Page 269 and 270:

5.5. The custom made vibrating orif

- Page 271 and 272:

5.14.Static electric field between

- Page 273 and 274:

6.6. Capillary wave created by the

- Page 275 and 276:

A.5. Drop diameter: 189 µm, impact

- Page 277 and 278:

A.29.Drop diameter: 203 µm, impact

- Page 280:

List of Tables 2.1. MVD of Freezing

- Page 283 and 284:

Imaging and Computer Simulations. T

- Page 285 and 286:

[42] GENT, R. W., N. P. DART and J.

- Page 287 and 288:

[70] KOROLEV, ALEXEI V., GEORGE A.

- Page 289 and 290:

[99] MUNDO, CHR., M. SOMMERFELD and

- Page 291 and 292:

[125] RYERSON, CHARLES C., GEORGE G

- Page 293 and 294:

[153] ŠIKALO Š., C. TROPEA and E.

- Page 296:

Curriculum Vitae Personal Informati