Put the value back in your supply chain 135 Kb - Cardinal Health

Put the value back in your supply chain 135 Kb - Cardinal Health

Put the value back in your supply chain 135 Kb - Cardinal Health

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

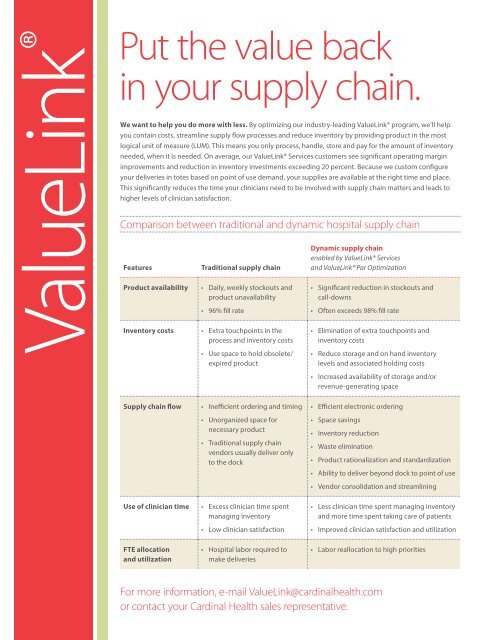

ValueL<strong>in</strong>k ®<br />

<strong>Put</strong> <strong>the</strong> <strong>value</strong> <strong>back</strong><br />

<strong>in</strong> <strong>your</strong> <strong>supply</strong> cha<strong>in</strong>.<br />

We want to help you do more with less. By optimiz<strong>in</strong>g our <strong>in</strong>dustry-lead<strong>in</strong>g ValueL<strong>in</strong>k® program, we’ll help<br />

you conta<strong>in</strong> costs, streaml<strong>in</strong>e <strong>supply</strong> flow processes and reduce <strong>in</strong>ventory by provid<strong>in</strong>g product <strong>in</strong> <strong>the</strong> most<br />

logical unit of measure (LUM). This means you only process, handle, store and pay for <strong>the</strong> amount of <strong>in</strong>ventory<br />

needed, when it is needed. On average, our ValueL<strong>in</strong>k® Services customers see significant operat<strong>in</strong>g marg<strong>in</strong><br />

improvements and reduction <strong>in</strong> <strong>in</strong>ventory <strong>in</strong>vestments exceed<strong>in</strong>g 20 percent. Because we custom configure<br />

<strong>your</strong> deliveries <strong>in</strong> totes based on po<strong>in</strong>t of use demand, <strong>your</strong> supplies are available at <strong>the</strong> right time and place.<br />

This significantly reduces <strong>the</strong> time <strong>your</strong> cl<strong>in</strong>icians need to be <strong>in</strong>volved with <strong>supply</strong> cha<strong>in</strong> matters and leads to<br />

higher levels of cl<strong>in</strong>ician satisfaction.<br />

Comparison between traditional and dynamic hospital <strong>supply</strong> cha<strong>in</strong><br />

Features<br />

Product availability<br />

Inventory costs<br />

Traditional <strong>supply</strong> cha<strong>in</strong><br />

• Daily, weekly stockouts and<br />

product unavailability<br />

• 96% fill rate<br />

• Extra touchpo<strong>in</strong>ts <strong>in</strong> <strong>the</strong><br />

process and <strong>in</strong>ventory costs<br />

• Use space to hold obsolete/<br />

expired product<br />

Dynamic <strong>supply</strong> cha<strong>in</strong><br />

enabled by ValueL<strong>in</strong>k® Services<br />

and ValueL<strong>in</strong>k® Par Optimization<br />

• Significant reduction <strong>in</strong> stockouts and<br />

call-downs<br />

• Often exceeds 98% fill rate<br />

• Elim<strong>in</strong>ation of extra touchpo<strong>in</strong>ts and<br />

<strong>in</strong>ventory costs<br />

• Reduce storage and on hand <strong>in</strong>ventory<br />

levels and associated hold<strong>in</strong>g costs<br />

• Increased availability of storage and/or<br />

revenue-generat<strong>in</strong>g space<br />

Supply cha<strong>in</strong> flow<br />

Use of cl<strong>in</strong>ician time<br />

FTE allocation<br />

and utilization<br />

• Inefficient order<strong>in</strong>g and tim<strong>in</strong>g<br />

• Unorganized space for<br />

necessary product<br />

• Traditional <strong>supply</strong> cha<strong>in</strong><br />

vendors usually deliver only<br />

to <strong>the</strong> dock<br />

• Excess cl<strong>in</strong>ician time spent<br />

manag<strong>in</strong>g <strong>in</strong>ventory<br />

• Low cl<strong>in</strong>ician satisfaction<br />

• Hospital labor required to<br />

make deliveries<br />

• Efficient electronic order<strong>in</strong>g<br />

• Space sav<strong>in</strong>gs<br />

• Inventory reduction<br />

• Waste elim<strong>in</strong>ation<br />

• Product rationalization and standardization<br />

• Ability to deliver beyond dock to po<strong>in</strong>t of use<br />

• Vendor consolidation and streaml<strong>in</strong><strong>in</strong>g<br />

• Less cl<strong>in</strong>ician time spent manag<strong>in</strong>g <strong>in</strong>ventory<br />

and more time spent tak<strong>in</strong>g care of patients<br />

• Improved cl<strong>in</strong>ician satisfaction and utilization<br />

• Labor reallocation to high priorities<br />

For more <strong>in</strong>formation, e-mail ValueL<strong>in</strong>k@card<strong>in</strong>alhealth.com<br />

or contact <strong>your</strong> Card<strong>in</strong>al <strong>Health</strong> sales representative.