Industrial Communication for Automation and Drives - Induteq

Industrial Communication for Automation and Drives - Induteq

Industrial Communication for Automation and Drives - Induteq

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

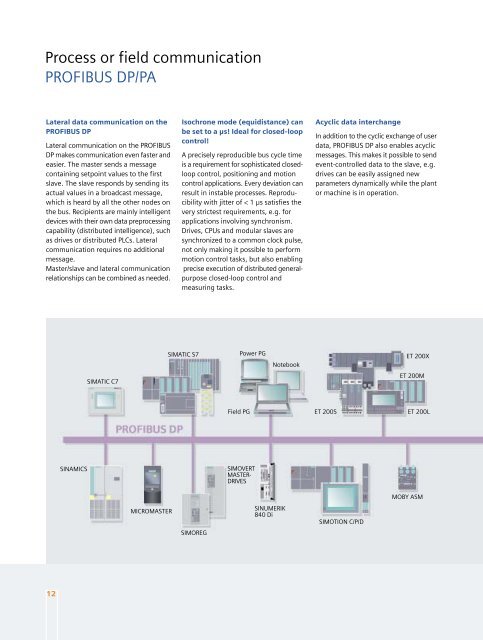

Process or field communication<br />

PROFIBUS DP/PA<br />

Lateral data communication on the<br />

PROFIBUS DP<br />

Lateral communication on the PROFIBUS<br />

DP makes communication even faster <strong>and</strong><br />

easier. The master sends a message<br />

containing setpoint values to the first<br />

slave. The slave responds by sending its<br />

actual values in a broadcast message,<br />

which is heard by all the other nodes on<br />

the bus. Recipients are mainly intelligent<br />

devices with their own data preprocessing<br />

capability (distributed intelligence), such<br />

as drives or distributed PLCs. Lateral<br />

communication requires no additional<br />

message.<br />

Master/slave <strong>and</strong> lateral communication<br />

relationships can be combined as needed.<br />

Isochrone mode (equidistance) can<br />

be set to a µs! Ideal <strong>for</strong> closed-loop<br />

control!<br />

A precisely reproducible bus cycle time<br />

is a requirement <strong>for</strong> sophisticated closedloop<br />

control, positioning <strong>and</strong> motion<br />

control applications. Every deviation can<br />

result in instable processes. Reproducibility<br />

with jitter of < 1 µs satisfies the<br />

very strictest requirements, e.g. <strong>for</strong><br />

applications involving synchronism.<br />

<strong>Drives</strong>, CPUs <strong>and</strong> modular slaves are<br />

synchronized to a common clock pulse,<br />

not only making it possible to per<strong>for</strong>m<br />

motion control tasks, but also enabling<br />

precise execution of distributed generalpurpose<br />

closed-loop control <strong>and</strong><br />

measuring tasks.<br />

Acyclic data interchange<br />

In addition to the cyclic exchange of user<br />

data, PROFIBUS DP also enables acyclic<br />

messages. This makes it possible to send<br />

event-controlled data to the slave, e.g.<br />

drives can be easily assigned new<br />

parameters dynamically while the plant<br />

or machine is in operation.<br />

SIMATIC S7<br />

Power PG<br />

Notebook<br />

ET 200X<br />

SIMATIC C7<br />

ET 200M<br />

Field PG<br />

ET 200S<br />

ET 200L<br />

SINAMICS<br />

SIMOVERT<br />

MASTER-<br />

DRIVES<br />

MOBY ASM<br />

MICROMASTER<br />

SINUMERIK<br />

840 Di<br />

SIMOTION C/P/D<br />

SIMOREG<br />

12