2013 Factory Catalog Vol. 7 - Classic Auto Air

2013 Factory Catalog Vol. 7 - Classic Auto Air

2013 Factory Catalog Vol. 7 - Classic Auto Air

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

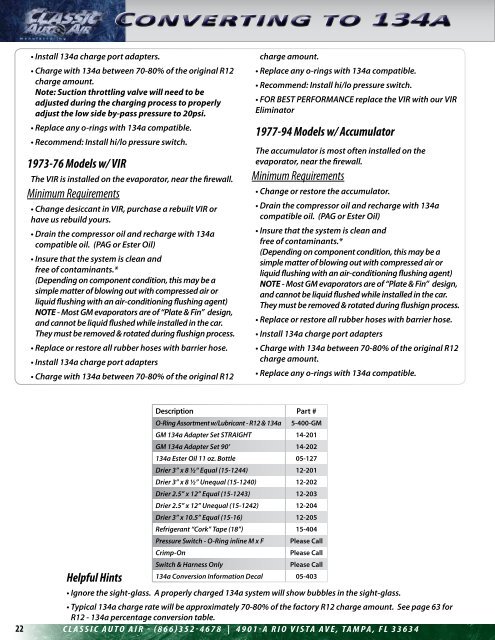

Converting to 134a<br />

• Install 134a charge port adapters.<br />

• Charge with 134a between 70-80% of the original R12<br />

charge amount.<br />

Note: Suction throttling valve will need to be<br />

adjusted during the charging process to properly<br />

adjust the low side by-pass pressure to 20psi.<br />

• Replace any o-rings with 134a compatible.<br />

• Recommend: Install hi/lo pressure switch.<br />

1973-76 Models w/ VIR<br />

The VIR is installed on the evaporator, near the firewall.<br />

Minimum Requirements<br />

• Change desiccant in VIR, purchase a rebuilt VIR or<br />

have us rebuild yours.<br />

• Drain the compressor oil and recharge with 134a<br />

compatible oil. (PAG or Ester Oil)<br />

• Insure that the system is clean and<br />

free of contaminants.*<br />

(Depending on component condition, this may be a<br />

simple matter of blowing out with compressed air or<br />

liquid flushing with an air-conditioning flushing agent)<br />

NOTE - Most GM evaporators are of “Plate & Fin” design,<br />

and cannot be liquid flushed while installed in the car.<br />

They must be removed & rotated during flushign process.<br />

• Replace or restore all rubber hoses with barrier hose.<br />

• Install 134a charge port adapters<br />

• Charge with 134a between 70-80% of the original R12<br />

charge amount.<br />

• Replace any o-rings with 134a compatible.<br />

• Recommend: Install hi/lo pressure switch.<br />

• FOR BEST PERFORMANCE replace the VIR with our VIR<br />

Eliminator<br />

1977-94 Models w/ Accumulator<br />

The accumulator is most often installed on the<br />

evaporator, near the firewall.<br />

Minimum Requirements<br />

• Change or restore the accumulator.<br />

• Drain the compressor oil and recharge with 134a<br />

compatible oil. (PAG or Ester Oil)<br />

• Insure that the system is clean and<br />

free of contaminants.*<br />

(Depending on component condition, this may be a<br />

simple matter of blowing out with compressed air or<br />

liquid flushing with an air-conditioning flushing agent)<br />

NOTE - Most GM evaporators are of “Plate & Fin” design,<br />

and cannot be liquid flushed while installed in the car.<br />

They must be removed & rotated during flushign process.<br />

• Replace or restore all rubber hoses with barrier hose.<br />

• Install 134a charge port adapters<br />

• Charge with 134a between 70-80% of the original R12<br />

charge amount.<br />

• Replace any o-rings with 134a compatible.<br />

Helpful Hints<br />

Description Part #<br />

O-Ring Assortment w/Lubricant - R12 & 134a 5-400-GM<br />

GM 134a Adapter Set STRAIGHT 14-201<br />

GM 134a Adapter Set 90’ 14-202<br />

134a Ester Oil 11 oz. Bottle 05-127<br />

Drier 3” x 8 ½“ Equal (15-1244) 12-201<br />

Drier 3” x 8 ½” Unequal (15-1240) 12-202<br />

Drier 2.5” x 12” Equal (15-1243) 12-203<br />

Drier 2.5” x 12” Unequal (15-1242) 12-204<br />

Drier 3” x 10.5” Equal (15-16) 12-205<br />

Refrigerant “Cork” Tape (18”) 15-404<br />

Pressure Switch - O-Ring inline M x F Please Call<br />

Crimp-On<br />

Please Call<br />

Switch & Harness Only<br />

Please Call<br />

134a Conversion Information Decal 05-403<br />

• Ignore the sight-glass. A properly charged 134a system will show bubbles in the sight-glass.<br />

• Typical 134a charge rate will be approximately 70-80% of the factory R12 charge amount. See page 63 for<br />

R12 - 134a percentage conversion table.<br />

22 <strong>Classic</strong> auto air - (866)352-4678 | 4901-A Rio Vista Ave, Tampa, FL 33634