Weinig Tools - OERTLI Werkzeuge AG

Weinig Tools - OERTLI Werkzeuge AG

Weinig Tools - OERTLI Werkzeuge AG

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Normal clamping<br />

Installation:<br />

1. Remove dirt and resin on clamping ledges and<br />

serrated back.<br />

2. Fit profiled cutters in serration.<br />

3. Slide clamping ledge in from the side.<br />

4. Axially align the clamping ledge and profiled cutters<br />

and tighten the middle clamping screw with half the<br />

specified torque.<br />

5. Check that the profiled cutters are correctly seated in<br />

the serration.<br />

6. Tighten the clamping screws from the centre<br />

outwards.<br />

7. Use an angled Allen key with shank to tighten the<br />

clamping screws uniformly (extensions and striking<br />

tools must not be used!)<br />

8. Tightening torque of the clamping screws:<br />

M 10: 25 – 26 Nm<br />

M 12: 30 – 33 Nm<br />

Never tension the complete cutter groove in<br />

one operation, otherwise the tool could<br />

become deformed.<br />

Do not use damaged Allen keys or keys on<br />

which the hexagon head has become round,<br />

as this may result in damage to the clamping<br />

screws.<br />

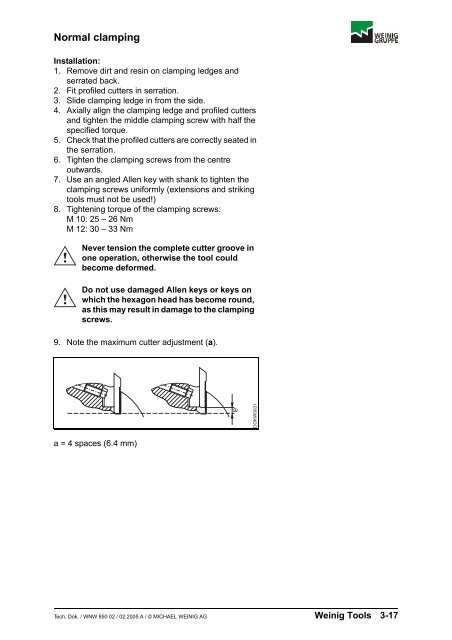

9. Note the maximum cutter adjustment (a).<br />

a<br />

DOKW0031<br />

a = 4 spaces (6.4 mm)<br />

Tech. Dok. / WNW 850 02 / 02.2005.A / © MICHAEL WEINIG <strong>AG</strong> <strong>Weinig</strong> <strong>Tools</strong> 3-17