1965-1979 part 1 - The Old Car Manual Project

1965-1979 part 1 - The Old Car Manual Project

1965-1979 part 1 - The Old Car Manual Project

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

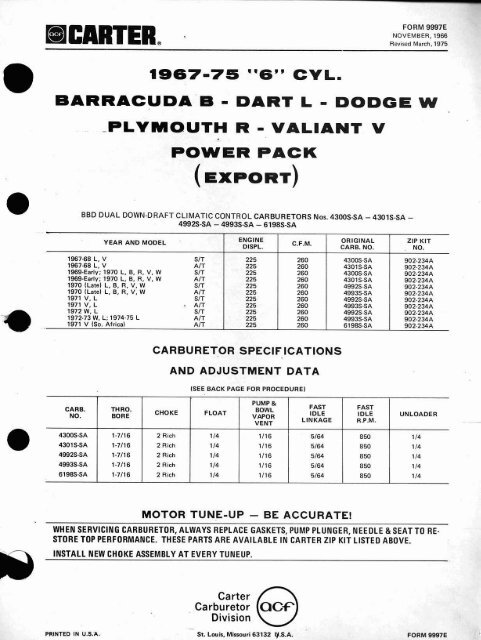

FORM 9997E<br />

NOVEMBER, 1966<br />

Revised March, 1975<br />

6775<br />

''6" CVL.<br />

BARRACUDA 6 - DART L - DODGE W<br />

- PLYMOUTH R - VALIANT V<br />

POWER PACK<br />

(EXPORT)<br />

BBD DUAL DOWN-DRAFT CLIMATIC CONTROL CARBURETORS NOS. 4300SSA - 43015-SA -<br />

4992S-SA - 499s-SA - 6198s-SA<br />

YEAR AND MODEL .<br />

ENGINE<br />

DISPL.<br />

C.F.M.<br />

ORIGINAL<br />

CARB. NO.<br />

ZIP KIT<br />

, NO.<br />

1967-68 L, V SIT<br />

1967.68 L. V AIT<br />

1969-Early; 1970 L, B. R, V, W<br />

SIT<br />

1969-Early; 1970 L. 6. R, V, W A1T<br />

1970 (Late) L, B, R. V, W S/T<br />

1970 (Late) L, &, R, V, W A/T<br />

1971 V, L SIT<br />

1971 V. L A1T<br />

1972 W, L SIT<br />

1972-73 W. L; 1974-75 L AlT<br />

1972 V (So. Africa) A/T<br />

225<br />

225<br />

225<br />

225<br />

225<br />

225<br />

225<br />

225<br />

225<br />

225<br />

225<br />

260<br />

260<br />

260<br />

260<br />

260<br />

260<br />

260<br />

260<br />

260<br />

260<br />

260<br />

4300s-SA<br />

4301s-$A<br />

4300s-SA<br />

4301 S-SA<br />

4992s-SA<br />

4993s-SA<br />

4992s-SA<br />

4993s-SA<br />

4992s-SA<br />

49935-SA<br />

61 98s-SA<br />

902-234A<br />

902-234A<br />

902-234A<br />

902-234A<br />

902-234A<br />

902-234A<br />

902-234A<br />

902-2 J4A<br />

902-234A<br />

902-234A<br />

90 2-234A<br />

CARBURETOR SPEClF ICATIONS<br />

AND ADJUSTMENT DATA<br />

(SEE BACK PAGE FOR PROCEDURE)<br />

PUMP &<br />

GARB. THRO. BOWL FAST FAST<br />

NO.<br />

BORE<br />

CHOKE FLOAT IDLE IDLE<br />

VAPOR<br />

LINKAGE R.P.M.<br />

VENT<br />

UNLOADER<br />

4300SSA 1-71t6 2 Rich 114 1/76 5164 850 114<br />

4301 SSA 1-7H6 2 Rich 114 1116 5164 850 114<br />

4992SSA 1-7116 2 R~ch 114 1/16 5/64 850 114<br />

4993SSA 1-7/16 2 Rich 114 1/16 5164 850 114<br />

6198SSA 1-7/18 2 Rich 114 1116 5/64 850 114<br />

R<br />

INSTALL<br />

MOTOR TUNE-UP - BE ACCURATE!<br />

WHEN SERVICING CARBURETOR, ALWAYS REPLACE GASKETS, PUMP PLUNGER, NEEDLE & SEAT TO RE-<br />

STORE TOP PERFORMANCE. THESE PARTS ARE AVAILABLE IN CARTER ZIP KIT LISTED ABO WE.<br />

NEW CHOKE ASSEMBLY AT EVERY TUNEUP.<br />

PRINTED IN U.S.'A.<br />

<strong>Car</strong>ter r\<br />

<strong>Car</strong>buretor I(CIC.Fr<br />

Division<br />

-<br />

St. Louis, Miasouri 63132 W.S.A.<br />

FORM 9991E

FORM 5685<br />

JANUARY, 1978<br />

DODGE W - PLVMOUTH R<br />

TQ FOUR-BORE DOWN-DRAFT CLllvlATlC CONTROL CARBURETOR NO. 91535<br />

MODEL<br />

ENGINE<br />

DISPL.<br />

C.F.M.<br />

ORIGINAL<br />

CARE NO.<br />

ZIP KIT<br />

NO.<br />

R, W (CALIF.) RIT<br />

440-4<br />

850<br />

91 535<br />

902-329<br />

CARBURETOR SPECIFICATIONS<br />

AND<br />

ADJUSTMENT DATA<br />

SEE BACK PAGE FOR PROCEDURE<br />

CARB.<br />

NO.<br />

BORE<br />

[kc:<br />

STAGE<br />

1<br />

PUMP<br />

STAGE<br />

2<br />

CHOKE<br />

CONTROL<br />

LEVER<br />

CHOKE<br />

BREAK<br />

HfGH LOW<br />

FAST IDLE<br />

CAM<br />

LINKAGE<br />

UNLOADER<br />

BOWL<br />

VAPOR<br />

VENT<br />

91 53s<br />

I-% (PI<br />

2-x tsj<br />

718<br />

112<br />

23/84<br />

3-318<br />

19/32 5132<br />

3/32<br />

511 6<br />

13116<br />

MOTOR TUNE-UP - BE ACCURATE!<br />

WHEN SERVICING CARBURETOR, ALWAYS REPLACE GASKETS, PUMP PLUNGER, NEEDLE & SEAT TO<br />

RESTORE TOP PERFORMANCE. THESE PARTS ARE AVAILABLE IN CARTER ZIP KIT LISTED ABOVE.<br />

INSTALL NEW CHOKE PULL OFF AND/OR CHOKE ASSEMBLY AT EVERY TUNE-UP.<br />

<strong>Car</strong>buretor<br />

Division<br />

Printed in U.S.A.<br />

St. Louis, Missouri 631 32 U.S.A.<br />

FORM 5685

CARBURETQR ADJUSTMENTS<br />

FLOAT LEVEL: With bowl cover inverted, gasket installed and<br />

floats resting on seated needle. the dimension of esch ftoat from<br />

bowl cover aasket to bottom side of floa* at outer end should be<br />

as specified: To adjust, band lever. NOTE: Never aliow lip of<br />

float to be pressed against needle when adjusting.<br />

SECONDARY THROlTLE LINKAGE: Open throttle valves to the<br />

wide open position. <strong>The</strong> primary and secondary throttle shaft<br />

stops. should contact casting at the same time. To adjust. bend<br />

link. Do not attempt to adjust secondary throttle valves to the<br />

wide open position.<br />

SECONDARY THROTTLE LEVER PICK-UP: Apply light pressure<br />

downward on the fast idle screw to move choke control lever to<br />

the wide open choke position. <strong>The</strong> clearance betwen pick-up<br />

lever and rop of secondary lever should be .075". To adiust,<br />

bend rear tang on throttle lever.<br />

PUMP: (STEP II Turn the idle speed screw indward until it iust<br />

touches the stop on throttle fever, then turn in two 12) more<br />

turns. With throttle connector rod installed in the center hole of<br />

pump arm. the dimension from top of bowl cover to top of<br />

plunger shaft should be as specified. To adjust. bend throttle<br />

connector rod.<br />

(STEP 2) With choke valve wids open, open throttle slowly until<br />

the secondary throttle shaft begins to move. Hold in this<br />

position. Measure again from top of bowl cover to top of plunger<br />

shaft. <strong>The</strong> dimension should be as specified. To adjust. bend<br />

pick-up arm on the primary throttle shaft dog.<br />

AIR VALVE OPENING: With air valve wide open there should be<br />

'X" between air horn wall and inner edge of air valw. To adjust,<br />

bend corner of air valva with pliers.<br />

AIR VALVE SPRING: 7. Loosen lock plug. Rotate adjustment plug<br />

(inner) clockwise to allow air valve to position itself to wide<br />

open. 2. Check to see that air valve and shaft are aperating<br />

freely. 3. Tn adjust, rotate adjustment plug [inner) counterclockwise<br />

until air valve just contacts the stop. <strong>The</strong>n turn 1%<br />

additional turn. While holding the adjustment plug in this<br />

position, tighten lock plug.<br />

CHOKE CONTROL LEVER: Off vehicle - place the carburetor on<br />

flat object with surface flush against bottom of flange. Close the<br />

choke valva by pushing on choke laver, with throttle <strong>part</strong>ially<br />

open. Measure the vertical distance from top of rod hole in<br />

control lever down to flat surface simulating carburetor bottom.<br />

This dimension should be as specified. To adjust. bend choke<br />

connector rod.<br />

DIAPHRAGM CONNECTOR ROD: With diaphragm stem fully<br />

depressed and air valve closed, there should be .WOW between air<br />

valve and stop. f o adjust, bend diaphragm connector rod.<br />

CHOKE HIGH AND LOW VACUUM BREAK: (STEP 11 Open<br />

throttle slightly to release the fast idle cam. Seat diaphragm by<br />

using outside vacuum source. Hold levers together with small<br />

clamp. Move choke valve toward the closed position by applying<br />

a light closing pressure to choke rod lever. <strong>The</strong> dimension<br />

between lower edge of choke valve and inner wall of alr horn<br />

should be as specified. To adjust. bend tang that contacts choke<br />

diaphragm rod.<br />

(STEP 21 Remove small clamp fram choke Iwer. Follow the<br />

same procedure as Step 1. <strong>The</strong> dimension should be as wac~fid.<br />

To adjust, place screw driver in tang and bend as requ~red.<br />

FAST IDLE CAM AND LINKAGE: With fast idle screw on second<br />

highest step of fan idle cam, close choke valve as far as possible.<br />

<strong>The</strong> dimension between the lower edge of choke valve and inner<br />

wall of air horn should be as specified. To adjust, bend<br />

connector rod.<br />

UNLOAIDER: With throttle valves wide open. close chok~ as far as<br />

possible without forcing, <strong>The</strong> dimension between lower edge of<br />

choke valve and innar walk nf air horn should be as specified. To<br />

adjust, bend front tang on fast idle control lever.<br />

FAST IDLE ON CAR: With fast idle screw on second step and<br />

against shoulder of first step of cam, adjust fast idle screw to<br />

specified R.P.M. on decal in engine com<strong>part</strong>ment.<br />

SOLENOID OPERATED VENT VALVE, ELECTRIC WlTH<br />

VACUUM ASSIST {IF EOUlPPEDl<br />

1. Solenoid unit must be adjusted before reinstalling on the<br />

carburetor.<br />

2. Measure the dimension between the edge of the solenoid<br />

housing and the vent valve operating lever with a drill of the<br />

proper dimension as listed in the Data Chart.<br />

3. To adjust turn screw (A) on valve Iwer.<br />

4. After adjusting, place rubber valve in arm and install on<br />

carburetor using the proper gasket.<br />

'<br />

PARTS LIST<br />

PART NO.<br />

'1 b.368<br />

7.328<br />

7.334s<br />

11B 487<br />

HE4BB<br />

13.326<br />

13.3275<br />

14,1057<br />

tr1.1058<br />

17.70<br />

*2@239<br />

*20 243<br />

*20 282<br />

21 252A<br />

ZP- 15<br />

Z4 35<br />

2510866<br />

30A 221<br />

a8 376s<br />

53A 5636<br />

61.84<br />

61,761<br />

61 873<br />

61.886<br />

61.915<br />

61.996<br />

61-4'10<br />

61.1104<br />

63.336<br />

63.4268<br />

64.4658<br />

6BBD<br />

65.81<br />

65.07<br />

68.1A<br />

72 85s<br />

' 751946<br />

95 40<br />

101 387<br />

lot nzt<br />

101~5215<br />

101.537<br />

PART NAME<br />

Flenp garksl .....................<br />

Air uelva .......................<br />

Chokevolve eesmbly ................<br />

Aur velve adjustment plug ..............<br />

Arr value lock plug ..................<br />

Chots $hell lavor ...................<br />

Air valve shalt & Imr bwmbly ...........<br />

Chokc counrer%halt laver ...............<br />

Choke lwcr loutof) ..................<br />

Pump dlshsrge check nesdle ...........<br />

Needle rani gssket ................ i2i<br />

Fusl inlet lilting gaakot ................<br />

ldle enr~chmcnt screw gasket ...........<br />

FIOR~ R P ~ ~ ~ ..................<br />

~ I Y izi<br />

Mcrerinq rod arm pin ..............<br />

FIO~~ pin ..................... izi<br />

Noedle & wnl srrambiy .............. 12)<br />

Irllc rnixtura scrcw ................ 121<br />

Pump jct & housing amrnbly ............<br />

For1 rdlo operating arm assembly ...........<br />

Fsrl irlle spood screN sprrns .............<br />

Pump fprlnq twwrrl ...............<br />

Idle mtxrurc & grounding xrsw spring ...... iai<br />

Aur valm spring ....................<br />

Vacuum plrtoo sprmg ................<br />

ldle wood rcrsw sprrng ................<br />

Idla! cnrlchmcnr dlnphrnom spring ..........<br />

Choke modularor rpring .............<br />

Rororner ..................... i5i<br />

Inmke chock reteinsr assembly ....:.......<br />

Pump plungsr eeembly ...............<br />

Step,upcover plnl~<br />

IL-HI ..............<br />

Slcpup cover plaro IR-Hi ..............<br />

Stcpup "iston cowr plate ..............<br />

Alt~~uds cornpunsator ................<br />

Irllc enrichment srrsmbly ............<br />

Mulcrlng rod I 069.'x.048"x.035'7 ....... i2i<br />

Irll. timtcr cap .................. [21<br />

trlle spccd rcrow ...................<br />

Pump orm screw .................<br />

Irjle l.nrlchmenr acrew ...............<br />

i?i<br />

Idlu a!nr~chrnent diaphrspn cover %rew .....(21<br />

PART NO.<br />

PART NAME<br />

101-596 Air choke valve& lever screw .......... I51<br />

101-616 Ewl ewer screw ................ 1101<br />

101.617 Cover plato %crew ................. 151<br />

101-618 Pump jet housing screw ...............<br />

101-628 Dlavhrsgm bracket scrw ...........-...<br />

101.667 Fast idle eperoiing lewr screw ..........<br />

101-680A Aluiuude cempcnrater rcrm ........... i?E<br />

101.693 Chokc counterlhafl lever screw ...........<br />

101.702 Far! ,dle speed rcrcw .................<br />

101410 Idle enrrchrnenl mow Ilong! ............-<br />

lOl.713A Bowl venl solenoid cover ...............<br />

111-110 Mcisring rod arm ...................<br />

111-122 Pumparm ......................<br />

1132JOS Choke coun~srrhelr &lever enemblv ........<br />

114-209 Choke lever ......................<br />

115507 Fasu Idle connector rod .............-..<br />

115-521 Wloke connenor rod .................<br />

115522 Choke duaphrogm connector rod<br />

...........<br />

115552 Throttle connxlw rDd ................<br />

117-190 Pump connccror link .................<br />

120-4M2 Primary mercrlng let {.OW") ...........(2!<br />

rZC-511S Secondary mctering jet 1.110") ...........<br />

121.662 Pump iet housing gasket ..............<br />

121.76% Allllude compenwror gaker .............<br />

121.709 ldle enrichmcnt casting gaxket ............<br />

121.818 Body llnnw qrrkcr ..................<br />

121.858 Bowl ucnr sol#:nord gwker ..............<br />

121.858 Alr hotn sskel ....................<br />

136.308 Choke diephrsgm wnnscror nod waher .......<br />

145.521 Pum~ psrwge rube ..................<br />

145.603 Choke diaohrogm hole ................<br />

156.109 Fuel Inlet luurtq ...................<br />

16B317S Stupup plseon & link ousmbly ............<br />

163.131 lluird X ring ................... 121<br />

164.42 Grommel son! .....................<br />

170.1228 ldlo cnrichmont covw ................<br />

17&14(195 Thcrmostanc coil, houi~ng rod asaembly ......<br />

186.184 Sccorrdary balfle plare ................<br />

202.664s Chokc diaphragm & bracket a-lv ........<br />

203.430$ Idle enrichmoot diaphrnqrn aslembly .........<br />

213.93s Solenold vcnt arrembly ................<br />

NOTE: Figures in parentheses indicete number of pieces used In one carburetor. Where no figure is shown, un!v one is used.<br />

*Available in Zia Kit only.

FORM 5684A<br />

February, 1978<br />

Revised April, 1978<br />

197lg "Vs" DODGE TRUCK<br />

TO FOUR-BORE DOWN-DRAFT CLIMATIC CONTROL CARBURETORS NOS. 9116S - 9117s -91185 -<br />

91498 - 9150s - 9190s<br />

MODEL<br />

ENGINE<br />

DISPL.<br />

C.F.M.<br />

DR1GtNAL<br />

CARB.<br />

ZIP-KIT<br />

NO.<br />

D, W-1.2, B-1.2.3 (CALIF.) A/T<br />

D, W, 8-3, M-3.4.5.6 (CALIF.) AIT<br />

D. W-1,2,3,B-2,3 AIT<br />

M.D. (CALIF.)<br />

AIT<br />

H.D. (CALIF.)<br />

AlT<br />

H.D. [NON-CALIF.)<br />

AIT<br />

H.D. ICALIF.1<br />

AlT<br />

440<br />

440<br />

440<br />

440<br />

440<br />

440<br />

440<br />

850<br />

850<br />

850<br />

850<br />

850<br />

850<br />

850<br />

9116s<br />

91 175<br />

91 18s<br />

9 1495<br />

9 150s<br />

91 51 S<br />

9190s<br />

902-329<br />

902-329<br />

902-329<br />

902-329<br />

902-329<br />

902-329<br />

902-329<br />

CARBURETOR SPECIFICATIONS<br />

AND<br />

ADJUSTMENT DATA<br />

SEE BACK PAGE FOR PROCEDURE<br />

GARB.<br />

NO.<br />

91 18s<br />

THROTTLE<br />

BORE<br />

---<br />

1-1/2(P)<br />

91165<br />

2-114 1s)<br />

1*1/2(P)<br />

2-114 1s)<br />

1-112 (PI<br />

,<br />

9150s<br />

9151s<br />

9190S<br />

2-1/4 lSl<br />

1-112 0')<br />

2-114 ($1<br />

1-112 {PI<br />

*-I/4 is)<br />

'-'I2<br />

2.314 1s)<br />

1*112 Ip'<br />

2-114 IS)<br />

FLOAT<br />

LEVEL<br />

718<br />

718<br />

718<br />

118<br />

718<br />

718<br />

,<br />

PUMP<br />

STAGE STAGE<br />

2<br />

112<br />

f/2<br />

112<br />

'I2<br />

112<br />

112<br />

112<br />

PUMP<br />

ROD<br />

LOCATION<br />

CHOKE CHOKE<br />

CONTROL BREAK<br />

LEVER HIGH<br />

-<br />

3-318 19/32 3/32 3132<br />

1 /2 13164<br />

1 -<br />

3 164<br />

3/64<br />

3/64<br />

5116<br />

23164<br />

23/64<br />

23164<br />

Center<br />

Center<br />

Center<br />

Center<br />

Center<br />

Center<br />

Center<br />

3-318<br />

3318<br />

3-318<br />

3-318<br />

3.318<br />

3-318<br />

19/32<br />

19/32<br />

$9132<br />

19132<br />

19/32<br />

19132<br />

3/32<br />

5/32<br />

3132<br />

3/32<br />

5132<br />

3132<br />

3/32<br />

3132<br />

5/32<br />

3/32<br />

3/32<br />

3132<br />

112<br />

1 /2<br />

112<br />

112<br />

TI2<br />

112<br />

13/64<br />

13164<br />

13164<br />

13164<br />

1 3/64<br />

13/64<br />

MOTOR TUNE-UP - BE ACCURATE!<br />

WHEN SERVICING CARBURETOR, ALWAYS REPLACE GASKETS, PUMP PLUNGER, NEEDLE & SEAT TO<br />

RESTORE TOP PERFORMANCE. THESE PARTS ARE AVAILABLE IN CARTER ZIP KIT LISTED ABOVE.<br />

INSTALL NEW CHOKE PULL OFF AND/OR CHOKE ASSEMBLY AT EVERY TUNE-UP.<br />

0<br />

<strong>Car</strong>ter<br />

QCf\ <strong>Car</strong>buretor<br />

Division<br />

Printed in U.S.A.<br />

St. Louis, Missouri 531 32 U.S.A.<br />

FORM 5684A, Pg. 1

PARTS LIST<br />

PART NAME PART NO.' PART NAME<br />

Grounding adjusting screw (91901<br />

Solenoid & bowl vent operating arm screw<br />

..........<br />

(9f16.17,50.90) .................<br />

Fast idle operating lever screw ............<br />

Choke countershaft lever screw ...........<br />

Fast idle speed screw .................<br />

ldleenrivhment screw (long) (9116,49,90) ......<br />

Bowl vent solenoid cover I91 16,17,49,505 ......<br />

Throdle modulator lock nut (9117,50)<br />

.......<br />

ESAtransducera~mblylocknut~9116,90~ ....<br />

Metering rod arm ...................<br />

Pump arm (9116,17.18,49,50.51) ..........<br />

Choke countershaft & lever assembly ........<br />

Choke lever ......................<br />

Fast idle connector rod ................<br />

Choke connector rod .................. .<br />

715-522 Choke diaphragm connector rod ...........<br />

115-552 Throttle connector rod ................<br />

117-190 Pumpconnectorlink .................<br />

1204098 Primery metering jet 1.098") (9176.<br />

18,49,51,90i .................(21<br />

12-9 Primary metering jet (.099") (9117.50) .....(21<br />

120.5125S Secondary metering jet 4.125") (4117,<br />

18,50,51) ...................(2)<br />

T20-5137S Secondary metering bt (.137") (9116,<br />

49,901 ..................... (2)<br />

*121-662 Pump jet housing gasket ...............<br />

*121-761 Altitudecompensatorgasket(911.6~<br />

.........<br />

*121-787 Body flanw gasket ..................<br />

*l?t-789 idle enrichment casting gasket 19116,49,90)<br />

.....<br />

*121-818 Body flange gasket (9190) ..............<br />

*121-858 Bowl vent solenoid gasket I91 16.17,49,50,90)<br />

....<br />

*121-859 A1rhorngasket(9116,f7,18,4$.50,51~ .......<br />

136-308 Chokediaphragm connectorrod washer .......<br />

*I45521 Pump passage tube ..................<br />

145.603 Choke diaphragm hose ................<br />

*150A-14 Pin spring (9116,181 .................<br />

158109 Fuel inlet fitting ~9116,77,18,49,50,51) .......<br />

756-249 Fuel inlet fitting 19190) ...............<br />

16G317S Stepup piston & link assembly ..........<br />

'163-137 (lud x ring ................... i2j<br />

16441 Grommet seal (9116.17.49,501 ............<br />

16443 Grommet gal (9190) .................<br />

170-1228 ldle enrichment cover I91 16.90) ...........<br />

'170-140s <strong>The</strong>rmostatic coil, housing & rod assembly<br />

(91 16.49.90) ...................<br />

170-14098 ~hermostati coil, housing 8( rod assembly<br />

(9117, t8.50.511 .................<br />

.......<br />

................<br />

.......<br />

18@271 Throttle mcdulator bracket 491 17,501<br />

186.184 Secondary baffle plare<br />

202-583s Throttre madulator assembly (9117.50)<br />

202-664s Choke diaphragm & bracket assembiy<br />

(91 16.49.901 ...................<br />

202466s Choke diaphragm & bracket assembly<br />

(9117, 18,50,511 .................<br />

*203-4305 Idle enrichment diaphragm assembly I91 16,901 ...<br />

213-BOA Transducer assembly (9390) . ............<br />

213938 Solenoid vent assembly (9116,17,44,50,90) .....

FORM 5683<br />

FEBRUARY, 1978<br />

a97a c=wsvg<br />

PLVMOUTH R CHRYSLER C -<br />

DODGE W<br />

TQ FOUR-BORE DUAL DOWN-DRAFT CLIMATIC CONTROL CARBURETOR NOS. 9109S - 97105 - 9'111s - 9712s - 9161s<br />

MODEL<br />

ENGINE<br />

DISPL.<br />

C.F.M.<br />

I<br />

ORIGINAL ,<br />

CARB. NO.<br />

ZIP KIT<br />

NO.<br />

C (Federal)<br />

A IT<br />

C (Altitude, Calif.)<br />

AD<br />

C {Canada)<br />

Am<br />

R, W (Canada) A IT<br />

C (Canada)<br />

AIT<br />

440<br />

440<br />

440<br />

440<br />

440<br />

850<br />

850<br />

850<br />

850<br />

850<br />

9109s<br />

91105<br />

9111s<br />

9112s<br />

9161 S<br />

902-329<br />

902-329<br />

902-329<br />

902-329<br />

902-329<br />

CARBURETOR SPECIFICATIONS<br />

AND<br />

ADJUSTMENT DATA<br />

(Sf E BACK PAGE FOR PROCEDURE3<br />

MOTOR TUNE-UP - BE ACCURATE!<br />

WHEN SERVICING CARBURETOR, ALWAYS REPLACE GASKETS, PUMP PLUNGER, MEEDkE & SEAT TO RESTORE<br />

TOP PERFORMANCE, THESE PARTS ARE AVAILABLE IN CARTER ZIP KIT LIST ED ABOVE.<br />

INSTALL NEW CHOKE ASSEMBLY AT EVERY TUNE UP.<br />

0<br />

<strong>Car</strong>ter<br />

0C-F <strong>Car</strong>buretor<br />

Division<br />

Printed in U.S.A.<br />

St. Louis, Missouri 63132 U.S.A.<br />

FORM 5683

CARBURETOR ADJUSTMENTS<br />

FLOAT LEVEL: With bowl cover Inverted, gasket ~nstalled and<br />

floats resting on seated needle, the dimension of each float from<br />

bawl cover gasket to bottom side of float at outer end should be<br />

as specified. To adiust, bend lever. NOTE. Never allow lip of<br />

float to be pressed against needle when adjusting.<br />

SECONDARY THROTTLE LINKAGE: Open throttle valves to the<br />

wide open position. <strong>The</strong> primary and secondarv throttle shaft<br />

stop, should contact castlng at rhe same time. To adjust, bend<br />

link. Do not attempt to adjust secondary throttle valves to the<br />

wide open position.<br />

SECONDARY THROTTLE LEVER PICK-UP: Apply light pressure<br />

downward on the fast idfe screw to move choke control.lever to<br />

the w~de open choke posit~on. <strong>The</strong> clearance between pick-up<br />

lever and top of secondary lever should be ,075". To adjust,<br />

bend rear tang on throttle lever.<br />

PUMP: (STEP 1) Turn the idle speed screw inward until it just<br />

touches the stop on the throttle lever, then turn In two (2) more<br />

turns. With throttle connector rod rnstalled in the center hole of<br />

pump arm, the dimension from top of bowl cover to top of<br />

plunger shaft should be as specified.<br />

{STEP 21 With choke valve wide open, open throttle slowly until<br />

the secondary throttle shaTt begins to move. Hold in this<br />

position. Measure again from top of bowl cover to top of plunger<br />

shaft. <strong>The</strong> dimension should be as specified. To adjust, bend<br />

pick-up arm on the primary throttle shaft dog.<br />

AIR VALVE OPEMING: With air vatve wide open there should be<br />

'/?" between air horn wall and inner edge of air valve. To adlust,<br />

bond corner of air valve with pliers.<br />

DIAPHRAGM CONNECTOR ROD: With diaphragm stem fully<br />

depressed and air valve closed, there should be .040" between air<br />

valve and stop. To adjust, bend diaphragm connector rod.<br />

CHOKE HIGH AND LOW VACUUM BREAK: (STEP 1) Open<br />

throttle s11ghtEy to release the fast idle cam. Seat diaphragm by<br />

using outside vacuum source. Hold levers together with small<br />

clamp. Move choke valve toward lhe closed position by applying<br />

a light closing pressure to choke rod lever. <strong>The</strong> dimension<br />

between lower edge of choke valve and inner walf of air horn<br />

should 'be as specified. To adjust, bend tang that contacts choke<br />

d raphragm rod.<br />

lSTEP 2) Remove small clamp from choke lever. Follow the<br />

same procedure as Step 1. <strong>The</strong> dimension should be as specified.<br />

To adjust, place screw driver in tang and bend as required.<br />

FAST IDLE GAM AND LINKAGE: With fast idle screw on second<br />

hjghest step of fast idle cam, close choke valve as far as possible.<br />

<strong>The</strong> dimension between the lower edge of choke valve and inner<br />

wall of alr horn should be as specified. TO adjust, bend<br />

connector rod.<br />

UNLOADER: With throttle valves wide open, close choke as far as<br />

poss~bte without forcing. <strong>The</strong> dimension between lower edge of<br />

choke valve and inner wall of air horn should be as specified. To<br />

adjust, bend front tang on fast idle control lever.<br />

ROWL VAPOR VENT ION CAR): With throttle valves set at curb<br />

idle, remove plug from air horn and insen a narrow ruter in hole.<br />

Rest ruler lightly on top of value. <strong>The</strong> dimension from top of<br />

valve to top of casting should be as specified. To adjust, bend<br />

operating lever.<br />

AIR VALVE SPRING: 1. Loosen lock plug. Rotate adjustment plug<br />

(inner) clockwise ta allow air valve to posrtlon itself to wide<br />

open. 2. Check to see that air valve and shaft are operating<br />

freely. 3. To adjust, ratate adjustment plug (Inner) counterclockwise<br />

until air valve just contacts the stop. <strong>The</strong>n turn I%<br />

additional turn. While holding the adjustment plug in th~s<br />

position, tighten lock plug.<br />

CHOKE CONTROL LEVER: Off vehicle - piece the carburetor on<br />

flat oblect with surface flush agalnst bottom of flange. Close the<br />

choke valve bv pushing on choke lever, with throttle <strong>part</strong>~alry<br />

open. Measure the vertical distance from top of rod hole in<br />

control lever down to flat surface simulating carburetor bottom.<br />

This dimension should be as specified. To adjust. bend choke<br />

connector rod.<br />

PARTS LIST<br />

SOLENOID OPERATED VENT VALVE, ELECTRlC WITH VAC-<br />

UUM ASSFST (IF EQUIPPED}: 1. Solenoid unit must be<br />

*<br />

adjusted before reinstalling on the carburetor. 2. Measure the<br />

d~rnens~on between the edge of the solenoid housing and the<br />

vent vatve operating lever with a drill of the proper dimension as<br />

listed in the Data Chart. 3. To adjust turn screw on valve lever. 4.<br />

After adjusting, place rubber valve in arm and Install on<br />

carburetor using the proper gasket.<br />

FAST IDLE ON CAR: W~th fast idle screw on second step and<br />

against shoulder of first step of cam, adjust fast idle screw to<br />

specified R.P.M. on decal in engine com<strong>part</strong>ment.<br />

TRANSDUCER: See car manufacturer's manual.<br />

Par1 No.<br />

PART NAhnc I Par1 No. PART MAME<br />

Flanrlu qnrkel . .<br />

A1: "*Ivv . .<br />

Ctv~kr~ u.llur~urrpmbly<br />

Buwl venu plurr 1rllM. 10. 11.611<br />

Apt v.?tuv ,~CI~U%I~P#>~ pruq , ,<br />

r l ~ r V.IIVP 10~k plllrr . . .<br />

Chok,. $41.,11 I*>,*#<br />

,in* "dl"* ,t>dft 1w4.r ,,,$,~"l,l.,<br />

Choke ~u~,n~rr.rrll.rl~ lauts<br />

Choks: lhx~. :o?rrwl .<br />

Pulllp tl~~chd~azu: ~ 11eut111~ ~ k<br />

h<br />

Nr'udl" 5LW q415kci , ,<br />

I~4.l 11111'1 11ll~olq q.dlk.1 .<br />

IIIIP, 1.111 1whln~111 ~CII~W 1101lLrl .<br />

A ! Bnal vcrll orrerarcrlg orm 141 111 .<br />

bJA-hLI2S Lblpnond npa,rnllrhg 1h:vsr 011emR1r . . . . . . . .<br />

61 BO F.III ~tltl. ~prq.rl $crow 3nrrn.t . . .<br />

61,761 Yvrno hp8lrx IUIHIWJ .<br />

61-R73 lrtlv mrxrvrr. & ~rnundlnfi rcrour rnrlrlo<br />

GI-RRG A,, ~,,IvP ~p,,r*g . . .<br />

lgl.sl? llnwl vl.vi .Ism >ornun 19111. 611 .<br />

, 13i<br />

61-918 Vacuvnl rrnrfr,t> spr snn lr11W. 10, 131 . . . .<br />

61-9211 V,,cqjum p?sr*,n ~l>~rrw) Wlt 1. Gl 1 , , ,<br />

61.8!;6 11lle sopurl rcrl.w spr~rbq .<br />

51 8Efl lrlla 4.r~ ~rhrncnrl~ael~~anm rprlw . . .<br />

61-11110 Choke mndvlelnr $lr#rnq 19117, 611 .<br />

63,336 n~.ii~~r~r~.<br />

834lriS Irslakc clllek rer.lnrwr erlrmllty<br />

6'1,465S Pumo plurkgsr ,~rr~mnlv<br />

G5 110 Sc~p up C,OU## 1>1.11? 1 lL.141 , ,<br />

fir,-R1 S~#.P.IIP crlu.8 r~l.~lb. lH.111<br />

81 1 iU3 ChnLv rnodallalnr rorrnq l!JlU9, 10. 111 . . . .<br />

. . . . . . 151<br />

101.707 I ari 111Ivry1awI rc~vur . . , ,<br />

101,710 I~IP l~l#r?rhrnrrlr rcrcw f1ong119110.1i. 12. 61 I<br />

101,713A 5~tenold vrnr wrevr 19109. 10. 1.2.611<br />

I31<br />

10Sb.Dl CSA lrmlduc~r arrumblv lock nut<br />

111 110<br />

111-122<br />

113-21OS<br />

111120'1<br />

V~-ien~rro rud arm<br />

.. .<br />

i i ~ o n BaawI u#.rlr

FORM 5682A<br />

MAY, 1978<br />

1978 "VW' DODGE TRUCK<br />

TC! FOUR BORE DOWN-DRAFT CLIMATIC CONTROL CARUBURETOR NOS. 9125s - 91298 - 9173s<br />

MODEL<br />

ENGINE<br />

D ISPL.<br />

C. F.M.<br />

ORIGINAL<br />

CARB. NO.<br />

ZIP KIT<br />

NO.<br />

0, W-7.2. B-1.2.3 M1T<br />

0, W-1.2. 8-1.2.3 AIT<br />

H.D.<br />

360<br />

360<br />

360<br />

850<br />

850<br />

850<br />

91255<br />

9126s<br />

91735<br />

902-329<br />

902-329<br />

902-329<br />

CARBURETOR SPECIFICATIONS<br />

AND<br />

ADJUSTMENT DATA<br />

(SEE RACK PAGE FOR PROCEDURE)<br />

CARB.<br />

NO,<br />

9'25s<br />

26S<br />

THROTTLE<br />

BORE<br />

1-112 (PI<br />

2-114 ($1<br />

1*112{P)<br />

2-1 14 (S)<br />

1-112(P)<br />

2-114 (S)<br />

FLOAT<br />

LEVEL<br />

7/8<br />

718<br />

718<br />

PUMP<br />

STAGE STAGE<br />

2<br />

PUMP<br />

ROD<br />

LOCATION<br />

LEVER<br />

--------<br />

112<br />

112<br />

17/32<br />

5/16<br />

5/16<br />

9/64<br />

Center<br />

Center<br />

Center<br />

CHOKE<br />

CONTROL<br />

3-318<br />

3-318<br />

3-318<br />

CHOKE<br />

BREAK<br />

HIGH LOW<br />

19132<br />

19/32<br />

19/32<br />

5/32<br />

3132<br />

9/64<br />

FAST IDLE<br />

CAM<br />

LINKAGE<br />

3/32<br />

3/32<br />

3/32<br />

UNLOADER<br />

112<br />

112<br />

7/64<br />

BOWL<br />

VAPOR<br />

VENT<br />

-<br />

13/64<br />

13164<br />

1 3164<br />

MOTOR TUNE-UP - BE ACCURATE!<br />

WHEN SERVICING CARBURETOR, ALWAYS REPLACE GASKETS, PUMP PLUNGER, NEEDLE % SEAT TO RESTORE<br />

TOP PERFORMANCE. THESE PARTS ARE AVAILABLE IN CARTER ZIP KIT LISTED ABOVE.<br />

INSTALL MEW CHOKE ASSEMBLY AT EVERY TUNE-UP.<br />

n <strong>Car</strong>ter<br />

<strong>Car</strong>buretor<br />

Division<br />

Printed in U.S.A.<br />

St. Louis, Missouri 631 32 U.S.A.<br />

FORM 5682A

FORM 5680<br />

February, 1978<br />

1978 "-V8"<br />

CHRVSLER CI- DODGE W<br />

CORDOBA - S PLYMOUTH R<br />

CHARGER X - ASPEN N - VOLARE H<br />

CeBARON F - DIPLOMAT G<br />

TQ FOUR-BORE DOWN-DRAFT CLIMAT lC CONTROL CARBURETORS NOS. 9104s - 9134s<br />

MODEL<br />

H. N. R, W, s, X A/T<br />

H,N,F,G.R,W,S.X.C<br />

AIT<br />

ENGINE<br />

DISPL.<br />

360-4<br />

360-4<br />

I<br />

C.F.M.<br />

850<br />

850<br />

ORIGINAL<br />

CAR8 NO.<br />

91045<br />

91 34s<br />

ZIP KIT<br />

NO.<br />

902-329<br />

902-329<br />

CARBURETOR SPECIFICATIONS<br />

AND<br />

ADJUSTMENT DATA<br />

SEE BACK PAGE FOR PROCEDURE<br />

MOTOR TUNE-UP - BE ACCURATE!<br />

WHEN SERVlClNG CARBURETOR, ALWAYS REPLACE GASKETS, PUMP PLUNGER, NEEDLE & SEAT TO<br />

RESTORE TOP PERFORMANCE. THESE PARTS ARE AVAILABLE IN CARTER ZIP KIT LISTED ABOVE.<br />

INSTALL NEW CHOKE PULL OFF ANDIOR CHOKE ASSEMBLY AT EVERY TUNE-UP.<br />

n <strong>Car</strong>ter<br />

<strong>Car</strong>buretor<br />

Division<br />

Printed in U.S.A<br />

St. Louis, Missouri 631 32 U.S.A. FORM 5680

FLOAT LEVEL: Wlth bowl cover inverted, gasket installed and<br />

floats resting on seated needle, the dimension of 'each float<br />

from bowl cover gasket to bottom side of froat at outer end<br />

should be as specified. To adjust, bend lever. NOTE: Never<br />

allow lip of float to be pressed against needle when adiustinq.<br />

SECONDARY THROTTLE LINKAGE: Open throttle valves to<br />

the wide open position. <strong>The</strong> primary and secondary rhrottle<br />

shaft stops, should contact casting at rhe same time. To adjust,<br />

bend link. Do not attempt to adlust secondarv throttle valves<br />

to the wide open position.<br />

SECONDARY THROTTLE LEVER PICK-UP: Apply light pressure<br />

downward on the fast idle screw to move choke control lever<br />

to the wide open choke position. <strong>The</strong> clearance between pick-up<br />

lever and top of secondary lever should be .075".,To adjust,<br />

bend rear tang on throttle lever.<br />

PUMP: (STEP 1) Turn the idle speed screw inward until it just<br />

tauches the stop on throttle lever, then turn in two (2) more<br />

turns. With throttle connector rod installed in the inner hole<br />

on (91041; outer hole (91341, the dimension from top of bowl<br />

cover to top of plunger shaft should be as specified. To adjust,<br />

bend throttle connector rod.<br />

(STEP 2) With choke valve wide open, open throttle slowly<br />

until the secondary throttle shaft begines to move. Hold in this<br />

position. Measure again from top of bowl cover to top of<br />

plunger shaft. <strong>The</strong> dimension should be as specified. To adjust,<br />

bend pick-up arm on the primary throttle shaft dog.<br />

CARBY RETOR ADJUSTMENTS<br />

hole in control lever down to flat surface s~mulating carburetor<br />

bottom. This dimension should be as specified. To adjust, bend<br />

choke connector rod.<br />

DIAPHRAGM CONNECTOR ROD: With d~aphragm stem fully<br />

depressed and air valve closed, there should be ,040" between<br />

air valve and stop. To adjust, bend diaphragm connector<br />

rod.<br />

CHOKE HlGH AND LOW VACUUM BREAK: (STEP 7E Ooen<br />

throttle sllahtlv to release the fast idle cam. Seat dia~hriarn<br />

bv using iutslde vacuum source. Hold levers together ~7th<br />

small clamp. Move choke valve toward the closed pos~tion by<br />

applying a light closing pressure to choke rod lever. <strong>The</strong><br />

dimension between lower edge of choke valve and inner wall<br />

of air hose should be as specified. To adjust, bend tang that<br />

contacts choke diaphragm rod.<br />

(STEP 2) Remove small clamp from choke lever. Follow rhe<br />

same procedure as Step 1. <strong>The</strong> dimension should be as specified.<br />

To adjust, place screw driver in tang and bend as required.<br />

FAST IDLE CAM AND LINKAGE: With fast Fdle screw on second<br />

highest step of fast idle cam, close choke valve as far as possible,<br />

<strong>The</strong> dimension between the lower edge of choke valve and inner<br />

wall of air horn should be as specified. To adjust. bend connector<br />

rod.<br />

UNLOADER: With throttle valves wide open. close choke as far<br />

as possible without forcing. <strong>The</strong> dimension between lower edge<br />

of choke valve and inner wall of air horn should be as specified,<br />

AIR VALVE OPENING: With air valve wide open there should be To adjust, bend front tang on fast idle control lever.<br />

'A" between air horn wall and inner edge of air valve. To adjust,<br />

bend corner of air valve with pliers. SOLENOID OPERATED VENT VALVE. ELECTRIC WITH<br />

VACUUM ASSIST (IF EQUIPPED): 1. Solenoid unit must be<br />

AIR VALVE SPRING: 1. Loosen lock plug. Rotate adjustment<br />

plug (inner) clockwise to allaw air valve to position itself to<br />

wide open. 2. Check to see that air vahe and shaft are operating<br />

freely. 3. To adjust, rotate adjustment plug (inner) counterclockwise<br />

until alr valve just contacts the stop. <strong>The</strong>n turn 1%<br />

additional turn. While holding the adjustment plug in this<br />

position, tighten lock plug.<br />

CHOKE CONTROL LEVER: Off vehicle - place the carburetor<br />

on flat object with surface flush against bottom of flange.<br />

Close the choke valve by pushing on choke lever, with throttle<br />

<strong>part</strong>ially open. Measure the vertical distance from to^ of rod<br />

adjusted before reinstalling on the carburetor. 2. Measure the<br />

dimension between the edge of the solenoid housing and the<br />

vent valve operating lever with a dri4l of the proper dimension as<br />

listed in the Data Chart. 3. To adjust turn scrw (A3 an valve<br />

lever. 4. After adjusting, place rubber valve in arm and instali on<br />

carburetor using the proper gasket.<br />

FAST IDLE ON! CAR: With fast idle screw on second step and<br />

against shoulder of first step of cam, adjust fast idle screw to<br />

specified A.P.M. on decal in engine com<strong>part</strong>ment.<br />

TRANSDUCER: See car manufaaurer" manual.<br />

PARTS LIST<br />

PART NO. PART NAME PART NO. PART NAME<br />

*1A-36B Flange gasket .......................<br />

7-328 Air valve ..........................<br />

7.3345 Choke valve assembly ...................<br />

110-487 Air valve adjustment plug<br />

.................<br />

118-488 Air valve lock plug .....................<br />

13.326 Choke shaft lever ......................<br />

13-327s Air valve shall & lever assembly .............<br />

14.1057 Choke countershafr lever .................<br />

14-1058 Choke lever (Outer) ....................<br />

77-70 Pump discharge check needle ...............<br />

'20-239 Needle seat gasket .................. (21<br />

*2&243 Fuel inlet fittrng gasket ..: ...............<br />

*2@282 Idle enr~chment screw gasket ...............<br />

21-2528 Float assembly ...................(21<br />

24-15 Metering rcd arm pin .........:<br />

.........<br />

24-35 Floar pqn ....................... 121<br />

'2510865 Needle & seat assembly ............... 121<br />

30A-221 Idle mixture screw .................. 121<br />

48-376s Pump jet & housing assembly 19134) ..........<br />

483835 Pump jet & housing assembly 19104) .........<br />

53A-563s Fasl ~dte operating arm assembly (9104) ........<br />

53A-5825 Solenold operating lever assembly 19104) ........<br />

61-84 Fast Idle speed screw spring ................<br />

61-762 Pump spring (Upper1. ...................<br />

61-873 Idle rnlxture & grounding screw spring (31 .......<br />

61-886 Aur valve spring .......................<br />

61.915 Vacuum plston spring ...................<br />

61-956 Idle speed screw spring ..................<br />

*El-970 ttfle enrichment diaphragm spring ............<br />

61-1 103 Choke modulator spring 191 34) .............<br />

61-13 W Choke modulator spring 191041 ............<br />

151<br />

'63-336 Retamer ........................<br />

*63-426s Illtake check retainer assembly ..............<br />

"64.465s Pump plunger assembly ..................<br />

6580 Step-up cover plate 1L-HI .................<br />

65.81 Step-up cover plate IR-H1 .................<br />

6584 Step-up plslon cover plate. ................<br />

72.395 Idle enr~chment assembly (9134) .............<br />

72-101s Idle enr~chrnenl assembly (9104) ............<br />

75-1940 Metering rod 191041 ....................<br />

75-1996 Moter~c~g rod I91 341 ....................<br />

96-40 Idle lim~ter cap .................... 121<br />

101.387 Idle speed screw (91341 ..................<br />

101-421 Pump arm screw ......................<br />

101-505 Solenold bracket screw 191041 ..............<br />

101-521s Idle enr~chment screw (91041 ............<br />

101-537s ldle enrichment diaphragm cover screw ..... 12)<br />

101-596 Air choke valve & lever screw ............ 15)<br />

101-616 Bowl cover screw ..................(101<br />

101-517 Cover plate screw ..................(31<br />

101-618 Pump let housine screw .................<br />

101-628 P~aphragrn bracket screw ................<br />

101-629 Grounding adjustment screw 49104) ...........<br />

101-635 Solenold bowl vent operating arm scrcw 191041 ....<br />

101-687 Fast idle aperarlng lever screw ............<br />

101-593 Throttle slialt screw<br />

..................<br />

101-702 Fast rdle speed screw ...............<br />

101-710 Idle enrichment screw (long) ............<br />

101-713A Bowl vent svlcnard cover ................<br />

105-87 ESA transducer assembly lock nur 197041 .....<br />

171-110 Metering rod arm 191341<br />

...............<br />

111-123 Pump arm 491041 . . . . . . . . . . . . . . .<br />

113-210s Choke countershalt & Ir!vcr assemblv . . . . . .<br />

134-209 Choke tever ........................<br />

115-507 Fast Idle corlnector rod ...............<br />

115-521 Choke connector rod<br />

135-522 Choke diaphragm conr~eclor<br />

..................<br />

rod .............<br />

115-552 Throtlle connector rud ......... - - - ..<br />

117-190 Pump ccnfiecror lank ...................<br />

120-4032 Primary rnelerrng let (9102) .......... 12)<br />

120-5110s Secondary meterlng iet ............... 121<br />

*121-662 Pump jer housing gasket ..................<br />

* 721-789 Idle enrlchmerlr castrl~g<br />

*121-818 Body flange gaskei ....................<br />

*I 21-858 Bowl vent solenoid gaskcr ..............<br />

gasket .............<br />

121-859 Air hurn gasket ....................<br />

136-308 Choke d~aphragm connector rod washer .........<br />

145-521 Pump passage tube ..................<br />

145.603 Choke d~aphragm hosr! . . . - - - .- . ,.<br />

156-109 Fuel 1r11er fttt~rlg ....................<br />

150-317s Step-up plslurl & I~nk assembly ............<br />

(21<br />

170-1228 Idle e~lr~chment cov~?r ..................<br />

170-1407s <strong>The</strong>rmostat~c COI!, housing & rod assembly .......<br />

'163-131 Quad X rlrlg . .................<br />

186-184 Secondary baffle plalc .................<br />

202-6655 Choke diaphragm & bracket assembly ..........<br />

+203-1305 Idle enruchrnent diaphragm ...............<br />

213-80A ESA trau>sducer assembly (91 04) . ...........<br />

213-93s Sulenatd venr assemblv .................<br />

213-98A Ground wlre & bracket assembly (9104) ........<br />

'Parts sold in Zip-Kit Only<br />

NOTE: Figures in par~othzsis rndicare number of pieces us& in one carburetor. Where no figure is shown only one is used.

'<br />

FORM 5681<br />

Januarv. 1978 . .<br />

1 7<br />

V<br />

DODGE W<br />

CORDOBA S--PLYMOUTH R<br />

CHARGER X - ASPEN N - VOLARE H<br />

LeBARON F - DlPLOMAT G<br />

DODGE TRUCK<br />

TQ FOUR-BORE DOWN-DRAFT CLIMATIC CONTROL CARBURETORS NOS.<br />

MODEL<br />

D, W, B-1, 2, 3 Dodge Trk. M IT<br />

D, W, 8-1, 2, 3 Dodge Trk. An<br />

H. N, F, G, R, S, X (Canada) An<br />

H, N, F.G. R,S, X1Calif.l An<br />

Dodge Truck L, D. (Canada)<br />

Am<br />

9123s - 9124s - 91373 - 9'1475 - 91528<br />

ENGINE<br />

DISPP.<br />

37 84<br />

3184<br />

3184<br />

318-4<br />

318-4<br />

C.F.M.<br />

285<br />

285<br />

285<br />

285<br />

285<br />

ORIGINAL<br />

CARB NO.<br />

91 23s<br />

Y 1 24s<br />

91 375<br />

91478<br />

91 528<br />

ZIP KIT<br />

NO.<br />

902-329<br />

902.329<br />

902-329<br />

902-329<br />

902-329<br />

CARBURETOR SPECIFICATIONS<br />

AND<br />

ADJUSTMENT DATA<br />

SEE BACK PAGE FOR PROCEDURE<br />

UNLOADER<br />

MOTOR TUNE-UP - BE ACCURATE!<br />

WHEN SERVICING CARBURETOR, ALWAYS REPLACE GASKETS, PUMP PLUNGER, NEEDLE & SEAT TO<br />

RESTORE TOP PERFORMANCE. THESE PARTS ARE AVAILABLE IN CARTER f lP KIT LISTED ABOVE.<br />

INSTALL NEW CHOKE PULL OFF AND/OR CHOKE ASSEMBLY AT EVERY TUNE-UP.<br />

r\ <strong>Car</strong>ter<br />

[QC-I <strong>Car</strong>buretor<br />

Division<br />

Prlnted in U.S.A.<br />

St. Louis, Missouri 63132 U.S.A. FORM 5681

CARBURETOR ADJUSTMENTS<br />

FLOAT LEVEL: Wrth bowl cover inverted, gasket installed and DIAPHRAGM CONNECTOR ROD: W~th d~aphragm stem fully defloats<br />

restlng on seated needle, the d~mension of each tloat from pressed and a11 valve c.losed, there should be ,040" betmn air<br />

bowl cover gasket to bottom side of float at outer end should he valve anri stnp To adlust. *>end diaphraam connector rod.<br />

as specifled. To adjust, bend lever. NOTE: Nwer allow lip of CHOKE HIGH AND LOW VACUUM B R f ~ ~ (S~EP : 1 Open<br />

@<br />

float to be pressed against needle with adjusting.<br />

thrr)ltle sltghlly to reledse the last rdle cam. Seat diaphragm by<br />

SECONDARY THROTTLE LINKAGE: Open throttle values to the using c~ulstde vacuum source. Hold levers together w~th small<br />

wrde open position <strong>The</strong> primary and secondary throttle shaft clamp Move choke valve toward the closed position by applying<br />

stops, should contact ~astina at the same time. To adiust. bend a liaht clns~nu DreSsUrE to choke rod lever. <strong>The</strong> dimens~on belink.<br />

Do not attempt to adlust secondaw throttle valves to the tween lower edge nf choke valve and inner wall of air horn<br />

wade open pes~tion.<br />

shnuld be as spec~fred. To adjust, bend tang that contacts choke<br />

draphlaqm rod<br />

SECONDARY THROTTLE LEVER PICK-UP: Apply liaht pressure<br />

downward on the fast idle screw to move choke control lever to (STEP 2) Rernt~ve small clamp from choke lever. Follow the<br />

the wide open choke posit~on. <strong>The</strong> clearance between pick-up same procedure as Step 1. <strong>The</strong> dimension should be as specified.<br />

lever and top of secondary lever should be ,075". To adjust, Ta adjust, place screw dr~ver In tang and bend a$ required.<br />

bend rear tang on throttle lever.<br />

FAST IDLE CAM AND LINKAGE: With fast Idle screw on second<br />

PUMP: (STEP 1) Turn the idle speed acrew inward until it just hlqhest step 01 fast ~dle cam. close choke valve as far as possible.<br />

touches the stop on rhrottle lever, then turn in two (2) more <strong>The</strong> dlrn~r~slon hcrwesn the lower edge of choke vdlve and Inner<br />

turns With throttle connector rod installed in the hole as speck wall ot d11 hrwn shrruld be as specrfled. To adjust. hend connecfied<br />

of pump arm, the dimension from top of bowl cover to top ll>l inli.<br />

of plunger shaft should be as specified. To adjust, bend throttle<br />

connector rod.<br />

UNLOADER: W11h thrr~rrle valves wide ODen. clcse choke as far as<br />

(STEP 2) With choke valve wide open, open throttle slowly unt~l<br />

the secondary throttle shaft begins to move. Hold In this positian.<br />

Measure agaln from top of bowl cover to top of plunger<br />

shaft. <strong>The</strong> dimension should be as specified. To adjust, bend<br />

pick-up arm on the primary throttle shaft dog.<br />

CHOKE CONTROL LEVER: Off vehicle - place the carburetor on<br />

flat object w~th surface flush against bottom of flange. Close the<br />

choke valve by pushing on choke lever, with throttle <strong>part</strong>ially<br />

open. Measure the verttcaf dlstance from top of rod hole in<br />

control lever down to flat surface simulating carburetor bottom.<br />

This dimension should be as specified. To adjusr, bend choke<br />

connector rod.<br />

AIR VALVE OPENING: W~th air valve wide open there should be<br />

Wr between air horn wall and inner edge of air valve. To adjust,<br />

bend corner of air valve with pliers.<br />

AIR VALVE SPRING: 1. Loosen lock plug. Rotate adjustment plug<br />

(inner) clockwise to allow air valve to position itself to wide<br />

open. 2 Check ta see that air valve and shaft are operating<br />

freely. 3. To adjust, rotate adjustment plug (inner) counterclockwise<br />

until air valve just contacts the stop. <strong>The</strong>n turn 1%<br />

additional turn. While holding the adjustment plug in this position,<br />

tighten lock plug<br />

I-ART NO. PART NAME<br />

*1A-388 Flange gasket<br />

....................<br />

7-328 Air vdlve .....................<br />

7-3345 Choke value asmmbly .................<br />

*118.294 Bowl vonr plug 19137) ................<br />

118-187 Air valvo adjustment plug ...............<br />

118.488 Air value lock plug ..................<br />

Choke shafi lwer ...................<br />

Air valve shefr & lever assembly ............<br />

Choke counisrshafl lever ...............<br />

Choko lever Iouterl ..................<br />

Ptrma disch~rge check nsedle ...........<br />

Needle sear gasket ................. i2i<br />

Fuel inlet fitting galkst ..............<br />

Float assembly .................. i2i<br />

Meroring rod rrnn pin .................<br />

Solenoid vent pin 191521 .............<br />

FIOSI pin ..................... izi<br />

Needle & seet assembly .............. 12)<br />

Idle mixture rcrsw ................ 12)<br />

Pump jet & housmg asmbly .............<br />

Bowl vent operating lever assembly (91371 ......<br />

Fast idle cporeting arm assembly (9123.24,47,52) . .<br />

$owl vent arm (91371 ................<br />

Solenoid opsreting lever aswmbly (9137.471 .....<br />

Fast ~dle speed screw spring ..............<br />

Pump spring luppar) ..............<br />

Idle mixture & grounding rcrew spring .....: i3i<br />

Air valve spring ....................<br />

Bowl vnnt arm spring 19131) .............<br />

Vacuum piston sprrng I9123,24,37.471 ........<br />

Idle spesd =re* rpri ................<br />

Choke modularor spring ..............<br />

Rsmnor ......................(Si<br />

Inieke check rstarnef asrsmbly ............<br />

Pump plunger asmmhly ................<br />

S~ewua cover plats 1C.H) ...............<br />

Sreo-up cover plnie (R-H I ...............<br />

Siepup piston cover plate ..............<br />

Alrrtuds compensaror 19147) .............<br />

...<br />

Mererrng rod (.064" x ,048" r .03!3'1 19147) 12)<br />

Motoring rod 4,067" r .MY x ,035") 19123.24.521 121<br />

M~tering rod (.070" x .057" x .04W4! 19137) 121<br />

...<br />

Idle lrmiter cap .................. 12)<br />

ldln wsed xrew I91 23,24,52) ............<br />

Puma orm screw ...................<br />

Solenord brackol screw {913?,47.521 .........<br />

Idle snrichmenr screw (9147) .............<br />

Alr chake valve & lever screw ...........(51<br />

PARTS LIST<br />

. .<br />

l~ctwt!en lower edg of<br />

p(~rs~tllr, w~lh(~ul tc~rrcng. <strong>The</strong> d~msns~ol\<br />

chokr. vitlvr and Inner wall of alr horn should he ;as specified. To<br />

adlnsl, trt!r~rl f~ontans on fast tdle control lever<br />

BOWL VAPOR VENT ION CARI: With throltle vdlues set at curb<br />

rclln, ternout! pluq from ar horn and Insert a narraw ruler In hole.<br />

RPSI r t~lw llrlhlly nn lop of valve. <strong>The</strong> d~mrns~on from top of<br />

valve Irr top rsf castlnq should he as sperrlted Tu adrust, bend<br />

opere~tina Itwt!r<br />

SOLENOID OPERATED VEHT VALVE, ELECTRIC WITH<br />

VACUUM ASSlST (IF EQU IPPEDJ<br />

1 Snlpr~o~rl urirt must he ad]rtsted before reinstalling on Fhe<br />

can t~uretor .<br />

2. Measure the drmenslon between the edge of the solenoid<br />

houstng and the vent valve operating lever wlth a dr~ll of the<br />

pcoprr drmens~on as l~sted In the Data Chart.<br />

3. To atllusr iurn scrpw on valve lever.<br />

4. After adjust~ng, place rubber valve In arm and install on<br />

carburetor uslng the proper gasket.<br />

FAST IDLE ON CAR: W~th fast idle screw on second step and<br />

against shoulder of first step of cam, adjust fast idle screw to<br />

specified R.P.M. on decal in engine com<strong>part</strong>ment.<br />

f RANSDUCER: See car manufacturer's manual.<br />

1 PART NO. PART NAME<br />

10.1.616 Bowl cwer screw<br />

201.617 Cover plate screw<br />

101-618 Pump let hous~ng<br />

101-628 Dlaphra~ bracket screw<br />

101-629<br />

101.635<br />

Grounding adlusting screw (9137.471<br />

Solenohd &bowl vent owretinaarm Kraw<br />

..............<br />

..............<br />

screw ...........<br />

..........<br />

....<br />

19137.47. 521 ..................<br />

TOT467 Fasr Idle operarlng lever xrew ...........<br />

101.693 Choke countershaft lever xrew ............<br />

101-702 Far1 ldls speed mew (9323.24.47.521 ........<br />

101.713A Selsn<strong>Old</strong> veni screw .............. (3)<br />

10SA.81 ESA rranMucer armblv lock ............<br />

111110 Meterlnqrodarm .................<br />

111122 Pumparm .......................<br />

113~2105 Choke countershaft & lwer arsemblv ........<br />

118-209 Choke leuer<br />

118.500 Bowl vent connecror rod ..............<br />

115-507 Fast Idle conneclor rod ................<br />

115.521 Choke connsctoc rod .................<br />

115-522 Choke d~aohrwm connector rod ...........<br />

115.552 Throttlc conn~ctorod ................<br />

117.190 Pump eonnsctor link<br />

.............<br />

320-4092 Prurnarv rneterrng let 1.092'") ..........: i2i<br />

120 51105 Secondarv melerlnq jet 1.1 10") ......... (2)<br />

-127.662 Pump let hous~ngasket ..............<br />

"127.761 Al~kcude comosnraror gasket 19147) .........<br />

"121.818 Body flangegasket ..................<br />

*121.858 Bawl vsnt solanord gasket ...............<br />

'121 859 Arr horn gesket ...................<br />

136-300 Throttle shaft sprlng warher 19123. 24. 37) ......<br />

736.308<br />

'745.521<br />

Chokedla~hragmconncctor rod washer ......<br />

Pump passage tube ..................<br />

745-603 Choke d~aphragm<br />

hore ..............<br />

145,622 Tube (9123.241 ..................!?i<br />

*t50A.14 'Pnn sarnng .......................<br />

156.109 Fuel Inlet fittrng ...................<br />

156.182 Tee (4123.241 ....................<br />

160 3178 Step-up prsian & lrnk assembly ..........<br />

*163131 QuadXr~ng.. ................ .izi<br />

*16&30 Grommet wal(91371 ................<br />

-164 43 Grammet sesl (9123.24.47.52) ............<br />

170-1d0E <strong>The</strong>rmortar~c toll, housing & rod arsernbly ......<br />

186.184 Secondary baffle plate ................<br />

202 665s Choke d~aphragm lP breckst esrembly ........<br />

213 BOA ESA Iranducer asmbly (9131.47) .........<br />

213.338 Solenord vent ammbly (9123.24.47.521 .......<br />

213.98A Ground *Ire & bracket nsaembly (9137.471<br />

NOTE; Figurss in perentheser indicate number 01 piaces uswd in one CUrbUfatQr. Where no figure is shown, only one is used.<br />

'Ports available in Zip-Kit only.<br />

....

FORM 5679A<br />

JANUARY, 1978<br />

Revised April, 1978<br />

1 "6"'<br />

DODGE W. - PLYMOUTH, R<br />

ASPEN N - VOLARE H<br />

Le BARON F - DIPLOMAT G<br />

DODGE TRUCK<br />

BBD DUAL DOWN-DRAFT CLIMATIC CONTROL CARBURETOR NOS. 8143s - 81565 - 8175s - 8201s<br />

MODEL<br />

ENG.<br />

DISPL.<br />

C. F.M.<br />

ORIGINAL<br />

CARB.<br />

ZIP KIT<br />

NO.<br />

H, N, F, G, R. W, S, X (Altitude) AIT<br />

D, W. 6-1 AIT<br />

H, N, F, MlT<br />

H, N, F, G. R, W, S, X (Export) A/T<br />

318<br />

318<br />

318<br />

318<br />

285<br />

285<br />

285<br />

285<br />

81 43s<br />

8156s<br />

81 758<br />

8201s<br />

902-325A<br />

902-325A<br />

902-325A<br />

902-325A<br />

CARBURETOR SPECIFICATIONS<br />

AND<br />

ADJUSTMENT DATA<br />

(SEE BACK PAGE FOR PRQCEDUREl<br />

CARE<br />

NO.<br />

THROm<br />

BORE<br />

FLOAT<br />

PUMP<br />

FAST IDLE<br />

CAM<br />

LINKAGE<br />

CHOKE<br />

VACUUM<br />

KICK<br />

UNLOAQER<br />

IDLE SETTING<br />

8143s<br />

81 568<br />

81755<br />

8201 S<br />

9-7/16<br />

'I -711 6<br />

1-7/16<br />

1-711 6<br />

114<br />

114<br />

1 14<br />

114<br />

15/32<br />

15132<br />

112<br />

112<br />

5/64<br />

5/64<br />

5164<br />

5/54<br />

7164<br />

7/64<br />

5132<br />

7/64<br />

9/32<br />

9132<br />

9132<br />

7/64<br />

See decal in engine com<strong>part</strong>ment<br />

MOTOR TUNE-UP - BE ACCURATE!<br />

WHEN SERVICING CARBURETOR, ALWAYS REPLACE GASKETS, PUMP PLUNGER, NEEDLE & SEAT TO RESTORE<br />

TOP PERFORMANCE, THESE PARTS ARE AVAILABLE kM CARTER ZIP KIT LISTED ABOVE.<br />

INSTALL NEW CHOKE ASSEMBLY AT EVERY TUNEUP.<br />

0<br />

<strong>Car</strong>ter<br />

0C-P <strong>Car</strong>buretor<br />

Division<br />

Printd in U.S.A.<br />

St. Louis, Missouri 631 32 U.S.A.<br />

FORM 5679A

FORM 5678<br />

DECEMBER, 1977<br />

BBD DUAL DOWN-DRAFT CLIMATIC CONTROL CARBURETOR NOS. 87493 - 8151s -<br />

8152s - 8153s - 8176s - 8180s<br />

MODEL<br />

ENGINE<br />

DISPL.<br />

C.F .M.<br />

ORIGINAL<br />

CRRB. NO.<br />

ZIP<br />

KIT NO.<br />

D. W, 5-1 (Non-Calif.) M/f<br />

D, W, 3-1 (Non.Ca1if.l AIT<br />

D, W, B-1 (Calil.1 MIT<br />

D. W. B-I (Cal1i.1 A/T<br />

D, W-1, 2, 3, 8-2, 3 (Non-Cal~f.) ALL/T<br />

D, W-I, B-l FCal~l.) AIT<br />

225<br />

225<br />

225<br />

225<br />

225<br />

225<br />

285<br />

285<br />

285<br />

285<br />

285<br />

285<br />

8149s<br />

81 51 S<br />

81 52s<br />

81 535<br />

87 765<br />

87 80s<br />

902-325<br />

902-325<br />

902-325<br />

902-325<br />

902-325<br />

902-325<br />

CARBURETOR SPECIFICATIONS<br />

AND<br />

ADJUSTMENT DATA<br />

(SEE BACK PAGE FOR PROCf DUREl<br />

CARB.<br />

NO.<br />

THRO.<br />

BORE<br />

FLOAT<br />

PUMP<br />

FAST IDLE<br />

LINKAGE<br />

VACUUM<br />

CHOKE<br />

KICK<br />

UNLOADER<br />

81 495<br />

8151s<br />

81 528<br />

81 53s<br />

81 76s<br />

81 80s<br />

1-7/16<br />

1-7/16<br />

1-7/16<br />

1-7/76<br />

1-7/16<br />

1-7/16<br />

1 14<br />

1 14<br />

1 14<br />

1 14<br />

114<br />

114<br />

15132<br />

15132<br />

15132<br />

1 5132<br />

15/32<br />

15132<br />

5164<br />

5164<br />

5/64<br />

5/64<br />

5164<br />

5164<br />

7164<br />

7164<br />

5/64<br />

7164<br />

5164<br />

7164<br />

9132<br />

9132<br />

9132<br />

9/32<br />

9/32<br />

9132<br />

MOTOR TUNE-UP - BE ACCURATE!<br />

WHEN SERVICING CARBURETOR, ALWAYS REPLACE GASKIETS, PUMP PLUNGER, NEEDLE & SEATTO RESTORE<br />

TOP PERFORMANCE; THESE PARTS ARE AVAILABLE IN CARTER ZIP KIT LISTED ABOVE.<br />

INSTALL NEW CHOKE ASSEMflLY AT EVERY TUNE-UP.<br />

n<br />

<strong>Car</strong>ter<br />

IQCP~<br />

w<br />

<strong>Car</strong>buretor<br />

Division<br />

Printed in U.S.A. St. Louis, Missouri 63132 W.S.A. FORM 5678

CARBURETOR ADJUSTMENTS<br />

FLOAT LEVEL: Hold float Ilp agalnsf seated needle I~ghtly <strong>The</strong><br />

dimens~on between top of float (at center) and tog of bowl<br />

should be as specified To adjust, bend Ilp ol float.<br />

PUMP: Turn curb idle screw two (2) lull turns clockwise from the<br />

seated position. <strong>The</strong> dirnens~on from the too of the pump shaft<br />

to the top of bowl cover should be as specified. To adjusr, luosen<br />

pump arm lock screw dnd revolve pump arrn Tighten screw<br />

METERING ROO: Loosen metering rod arm screw, press downward<br />

on plston plate untrl mpterlng rods bottom. W~th thrott!e valve<br />

seated revolve metering rod arm un11l Irp contacts piston plate,<br />

then rlyhten clamp screw.<br />

FAST IDLE LINKAGE: With fast idle screw on the second hrghest<br />

step 01 cam, the dimension between the top edge of choke, valve<br />

and wall of alr horn should be as specifled. To adlust, bend<br />

connector rod<br />

VACUUM CHOKE BREAK: By using an outside vacuum source<br />

fully depress d~aphragm and close choke valve as far as possible<br />

wlthout forcing. <strong>The</strong> dimens~on berween top edge of choke valve<br />

and wall of alr horn should be as spectfied. To adjust, open or<br />

close the "U" bend of connecror Irnk.<br />

UNLOADER: With throttle valves wlde open close choke valve as<br />

far as possrble without forccng. <strong>The</strong> dlrnension between top edge<br />

of choke valve and wall 01 alr horn should be as spec~fied. To<br />

adjusf, bend rang on lhrottle lever<br />

VACUUM THROTTLE POSITIOSUER: Accelerate engine manually<br />

tu approxrmately 2500 R.P.M., loosen lock nut on poslrloner<br />

a_nd rotdte unit until stem just contacts throttle lever. Release<br />

thrortle and dowlv rotate unit to decrease engrne f3.P.M until a<br />

sudden drag occurs (appr~x. 1800 R.P.M.). At thls point contlnuc<br />

decreas~ny unit 114 additional turn, then t~ghten lock nut.<br />

Accelerate engine manually to 2500 R P.M. and then release,<br />

engine should return to narmal idle.<br />

BOWL VENT: Turn curb ~dle screw two turns cfockwise after it lust<br />

contacts stop Wlth ~hrottlc held closed, a 3/32 drill should fit<br />

between the grommet seal and its seat. wtth only a sl~ght drag on<br />

the drill. Drill guage must be positioned to touch the roll valve<br />

pin while gauglng the valve. To adjust, bend tang<br />

PARTS LIST<br />

PART NO, PART NAME 1 PARTNO. PARTNAME<br />

Flange gaske~ ........................<br />

Th~otll~. ualvr: 18149) ................(21<br />

Throttle valv~: 18151, 52, 53. 76,801 ....... (21<br />

Thruttle shall & lever assemblr (8152) .........<br />

Thrmltle shalt & fever assembly 18149. 57. 53, 76, 801<br />

Choke valve (8149)<br />

....................<br />

Choke valve 18151, 52, 53, 76, 801 ...........<br />

Choke lever & shaft assembly ...............<br />

Choke lever .........................<br />

Needle sear gasket .....................<br />

Floa~ assembly .......................<br />

Float pin ..........................<br />

Neerllt: & seal assembly ..................<br />

Idle mixtu~e screw .................. 12)<br />

Thrnrtle shdll collar ...................<br />

Idit: & Ids1 idle speed screw spring ......... (21<br />

Vacuum pisron splinq ................(21<br />

Purnl~<br />

Idle mixtu~e<br />

(2)<br />

sprlrlq .........................<br />

screw sprin~ ..............<br />

Throt tie reiurn spring (81761 ..............<br />

Throttlerelurnspring 18149,51.52,53,801. .. 421<br />

Floa~ gin re~ainer<br />

(2)<br />

.....................<br />

Retainer ........................<br />

Pump plunger & rod dssembly .............<br />

Muering rud 4.071 X .0571(8176) ......... (2)<br />

Metering rod LO675 X .0573(81493 ........ (21<br />

Meleriny rut1 LO65 X .0571(8152, 531 ....... (21 .<br />

Mereringrod1.068X.0571(8151) ......... (2)<br />

Metering rod LO645 X .0573(8180) ........ (2)<br />

Idle mixture screw limiler cap ........... 12)<br />

Fas~ idle speed screw. ...................<br />

Air horn screw assembly ....,..........(41<br />

Choke diaphragm bracket screw .......... (21<br />

Body screw assembly ................(2)<br />

Idle speed sc~ew ......................<br />

Fasl idle cam screw ...................<br />

Choke valve screw .................. C2)<br />

Chuke lever screw .....................<br />

Vnnturi cluster screw ................(21<br />

Body flange screw assembly .............(2)<br />

Pump & metering rod arm screw .............<br />

Air horn KrPw assembly iexc. 87 80) ....... (2)<br />

Dust cover screw ......................<br />

Throttl~: valve screw ................. (4)<br />

Lead shol ..........................<br />

Leadshot ....................... 12)<br />

Modulator lock nut C8176) ................<br />

Meter~t)y rod arm ......................<br />

Pumparm ..........................<br />

Pump & metering rod countershaft assembly ......<br />

Choke connecror rod ...................<br />

Thruttfe connector rod ..................<br />

Fasl idle connector rod ..................<br />

Pump discharge check ball ................<br />

Pump rrltake check ball ..................<br />

Pump link ..........................<br />

Venluri cuver assembly (8176) ..............<br />

Dus~ cnver ..........................<br />

Venturi cover assembly ..................<br />

Main rnelering je~ (.086")(8149. 51, 52. 53, 80) . (23<br />

Main rnelering jet (.092")(8176) ............<br />

Vrnluri housing gaskel ..................<br />

Dusl cover gasket ......................<br />

Bndy gasket .........................<br />

Ventuu I cover gasket ...................<br />

Body ffarlge gasket ....................<br />

Pump & meteriny rod arm washer ......... (2)<br />

Choke diaphragm hose ................ (21<br />

Choke diaphragm lee ...................<br />

Vdcuum prslon assembly .................<br />

Grommei seal ........................<br />

<strong>The</strong>rmostatic coil, housing & rod assembly .......<br />

Bracket modulator 181763 ................<br />

Fast idle cam C8149. 52) .................<br />

Fas~ idle cam 18151, 53. 76, 80) .............<br />

Fuel bowl baffle ......................<br />

Throttle modulator 18176) ................<br />

Choke diaphragm & bracket assembly (8176) .....<br />

Choke diaphragm & bracket assembly lexc. 81763 ...<br />

NOTE: Figur+?s ,sn pamn rhr!ssrs indicate rrl~rnber of piucss used in one carburutor. Wlrare no Iigurs is shown. only one is used.<br />

*Available in Zip Kit Only.

FORM 56778<br />

DECEMBER, 1977<br />

Revised April, 1978<br />

. 9<br />

-<br />

7 "6"<br />

DODGE W. PLYMOUTH, R<br />

ASPEN N = VOLAR~ H<br />

DIPLOMAT G LEBARON F<br />

BBD DUAL DOWN-DRAFT CLlMATrC CONTROL CARBURETOR NOS. 8136s - 81 37s - 8173s - 8174s -<br />

8177s - 8217s - 82188<br />

MODEL<br />

EMG.<br />

DISPL.<br />

C.F.M.<br />

ORIGINAL<br />

CAR&.<br />

ZIP KIT<br />

NO.<br />

Ha N, F, G, R, W<br />

MIT<br />

H,N,F,G.R,W./~~OOI~S.)<br />

A/T<br />

Mexico<br />

MIT<br />

Mexico<br />

AIT<br />

H, N, F, G, R, W, (4000 lbs.1 {Canada) AIT<br />

H, N, F. Gt R. W A IT<br />

H, N,F,G,R,W A/T<br />

225-2<br />

225-2<br />

225-2<br />

225-2<br />

225-2<br />

225-2<br />

225-2<br />

220<br />

220<br />

220<br />

220<br />

220<br />

220<br />

220<br />

81 36s<br />

8137s<br />

81 735<br />

81 745<br />

81775:<br />

821 75<br />

82 188<br />

902325A<br />

902-325A<br />

902-325A<br />

902-325A<br />

902-325R<br />

902-325A<br />

902-J25A<br />

CARBURETOR SPECIFICATIONS<br />

AND<br />

ADJUSTMENT DATA<br />

(SEE BACK PAGE FOR PROCEDURE)<br />

NO.<br />

Eat<br />

FLOAT<br />

PUMP<br />

FAST IDLE<br />

CAM<br />

LINKAGE<br />

CHOKE<br />

VACUUM<br />

KICK<br />

UNLOADER<br />

IDLE SEITING<br />

81365<br />

81 375<br />

81 73s<br />

81 745<br />

81 77s<br />

82178<br />

8218s<br />

1-7/16<br />

1-7116<br />

1-7116<br />

1-7/16<br />

1-7116<br />

1-7/16<br />

7-7/76<br />

114<br />

114<br />

f 14<br />

114<br />

114<br />

114<br />

114<br />

15/32<br />

15132<br />

112<br />

112<br />

112<br />

$12<br />

112<br />

5164<br />

5/64<br />

5/64<br />

5164<br />

5164<br />

5/64<br />

5164<br />

7/64<br />

7164<br />

7/64<br />

7164<br />

7/64<br />

7/64<br />

7164<br />

9132<br />

9132<br />

9132<br />

9132<br />

9132<br />

9/32<br />

9/32<br />

See decal in englne cam<strong>part</strong>rnant<br />

MOTOR TUNE-UP - BE ACCURATE!<br />

WHEN SERVIClf G CARBURETOR, ALWAYS REPLACE GASKETS, PUMP PLUNGER, NEEDLE & SEAT TO RESTORE<br />

TOP PERFORMANCE, THESE PARTS ARE AVAILABLE IN CARTER ZIP KIT LISTED ABOVE.<br />

INSTALL HEW CHOKE ASSEMBLY AT EVERY TUNEUP.<br />

/7 carter<br />

<strong>Car</strong>buretor<br />

Division<br />

Printed in U.S.A.<br />

St. Louis, Missouri 63132 U.S.A.

FORM 5664A<br />

December, 1976<br />

Revised Jan., 1978;<br />

CHRYSLER C, DODGE W,<br />

CARDOBA S - PLYMOUTH R -<br />

CHARGER X<br />

TQ FOUR-BORE DOWN-DRAFT CLEMATIC CONTROL CARBURETORS NOS. 9077s - 91035 - 9108s - 9140s<br />

MODEL<br />

ENGINE<br />

DISPL.<br />

C.F.M.<br />

ORIGINAL<br />

CAAB. NO.<br />

ZIP KIT<br />

NO.<br />

1977,R,W,S.X,P,D,C1Non-Calif.) . A n<br />

1977, A, W, S, X, P, D, C Won-Callf.1 AfT<br />

1978, R, W, S, X, C (Canada) RfT<br />

1978, R. W, S, X, C {Federal 1 AIT<br />

400<br />

400<br />

400<br />

400<br />

850<br />

850<br />

850<br />

858<br />

9077s<br />

9103s<br />

91 08s<br />

91405<br />

902-3 1 0<br />

902-31 0<br />

902-31 0<br />

90231 0<br />

CARBURETOR SPECIFICATIONS<br />

AND<br />

ADJUSTMENT DATA<br />

SEE BACK PAGE FOR PROCEDURE<br />

1.1-12 (PI 718<br />

9140s 1 2-114 IS1 I<br />

112<br />

5116<br />

Center 3-318 19/32 5/32 3132 511 6 13/16<br />

MOTOR TUNE-UP - BE ACCURATE!<br />

WHEN SERVICING CARBURETOR, ALWAYS REPLACE GASKETS, PUMP PLUNGER, NEEDLE & SEAT TO<br />

RESTORE TOP PERFORMANCE. THESE PARTS ARE AVAlLARLE IN CARTER ZIP KIT LISTED ABOVE.<br />

INSTALL NEW CHOKE PULL OFF AND/OR CHOKE ASSEMBLY AT EVERY TUNEUP.<br />

0<br />

<strong>Car</strong>ter<br />

QCP <strong>Car</strong>buretor<br />

Division<br />

Printed in U.S.A.<br />

St. Louis, Missouri 63132 U.S.A.<br />

FORM 5664A

FLOAT LEVEL: With bowl cover inverted, gasket installed and<br />

floats resting on seated needle, the dimension of each float from<br />

bowl cover gasket to bottom side of float at outer end should be<br />

as spectfied. To adjust bend lever. MOTE: Never allow lip of<br />

float to be pressed against needle when adjusttng.<br />

SECONDARY THROTTLE LINKAGE: Open throttle va(ves to the<br />

w~de open position. <strong>The</strong> primary and secondary throttle shaft<br />

stops, should contact casting at the same time. To adjust bend<br />