Fluorescence X-ray Spectrometer System ZSX Series - Rigaku

Fluorescence X-ray Spectrometer System ZSX Series - Rigaku

Fluorescence X-ray Spectrometer System ZSX Series - Rigaku

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

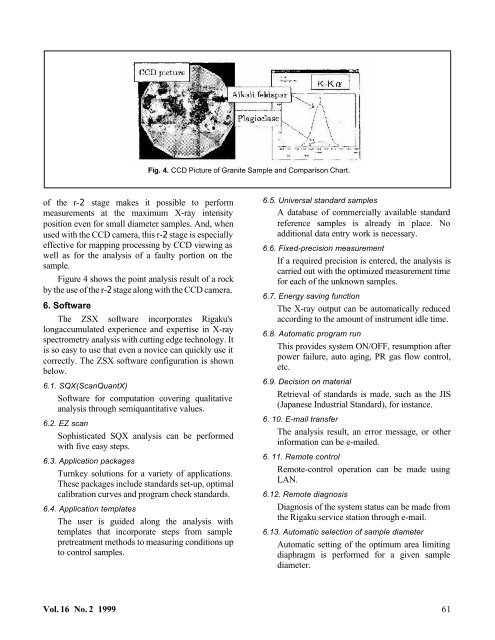

Fig. 4. CCD Picture of Granite Sample and Comparison Chart.<br />

of the r-2 stage makes it possible to perform<br />

measurements at the maximum X-<strong>ray</strong> intensity<br />

position even for small diameter samples. And, when<br />

used with the CCD camera, this r-2 stage is especially<br />

effective for mapping processing by CCD viewing as<br />

well as for the analysis of a faulty portion on the<br />

sample.<br />

Figure 4 shows the point analysis result of a rock<br />

by the use of the r-2 stage along with the CCD camera.<br />

6. Software<br />

The <strong>ZSX</strong> software incorporates <strong>Rigaku</strong>'s<br />

longaccumulated experience and expertise in X-<strong>ray</strong><br />

spectrometry analysis with cutting edge technology. It<br />

is so easy to use that even a novice can quickly use it<br />

correctly. The <strong>ZSX</strong> software configuration is shown<br />

below.<br />

6.1. SQX(ScanQuantX)<br />

Software for computation covering qualitative<br />

analysis through semiquantitative values.<br />

6.2. EZ scan<br />

Sophisticated SQX analysis can be performed<br />

with five easy steps.<br />

6.3. Application packages<br />

Turnkey solutions for a variety of applications.<br />

These packages include standards set-up, optimal<br />

calibration curves and program check standards.<br />

6.4. Application templates<br />

The user is guided along the analysis with<br />

templates that incorporate steps from sample<br />

pretreatment methods to measuring conditions up<br />

to control samples.<br />

6.5. Universal standard samples<br />

A database of commercially available standard<br />

reference samples is already in place. No<br />

additional data entry work is necessary.<br />

6.6. Fixed-precision measurement<br />

If a required precision is entered, the analysis is<br />

carried out with the optimized measurement time<br />

for each of the unknown samples.<br />

6.7. Energy saving function<br />

The X-<strong>ray</strong> output can be automatically reduced<br />

according to the amount of instrument idle time.<br />

6.8. Automatic program run<br />

This provides system ON/OFF, resumption after<br />

power failure, auto aging, PR gas flow control,<br />

etc.<br />

6.9. Decision on material<br />

Retrieval of standards is made, such as the JIS<br />

(Japanese Industrial Standard), for instance.<br />

6. 10. E-mail transfer<br />

The analysis result, an error message, or other<br />

information can be e-mailed.<br />

6. 11. Remote control<br />

Remote-control operation can be made using<br />

LAN.<br />

6.12. Remote diagnosis<br />

Diagnosis of the system status can be made from<br />

the <strong>Rigaku</strong> service station through e-mail.<br />

6.13. Automatic selection of sample diameter<br />

Automatic setting of the optimum area limiting<br />

diaphragm is performed for a given sample<br />

diameter.<br />

Vol. 16 No. 2 1999 61