A General Purpose Fiber-Optic Hydrophone Made of Castable Epoxy

A General Purpose Fiber-Optic Hydrophone Made of Castable Epoxy

A General Purpose Fiber-Optic Hydrophone Made of Castable Epoxy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Since the normalized sensitivity is proportional to AL/L, the sensitivity <strong>of</strong> a hydrophone element based on<br />

the integrated strain on the surfaces <strong>of</strong> a flexural plate will also be proportional to the ratio <strong>of</strong> yield strength<br />

to Young's modulus.<br />

It is possible to use the size <strong>of</strong> the air gap in the dual-plate hydrophone element to control the maximum<br />

strain experienced by the glass fiber and to provide support at depths which are greater than those given be<br />

equation (5)23. This is accomplished, as shown in Figure 3, by choosing the plate spacing provided by<br />

the air gap to be twice the displacement <strong>of</strong> a single plate at the maximum operating pressure. The<br />

displacement <strong>of</strong> the center <strong>of</strong> a thin clamped plate, z, is given26 as<br />

3(1 -<br />

zc=<br />

128Eh3<br />

(8)<br />

With the plates in contact, the hydrophone element will be protected from catastrophic failure at the<br />

expense <strong>of</strong> becoming acoustically insensitive until the pressure is once again reduced below 1max<br />

3.1 Material Selection<br />

3. HYDROPHONE ELEMENT CONSTRUCTION<br />

A castable epoxy was chosen as the capsule material so that the fiber coils could be cast directly into<br />

the sensing plates <strong>of</strong> the hydrophone. This also facilitated the fabrication <strong>of</strong> plates which were <strong>of</strong> uniform<br />

thickness. Casting the sensor capsule as a single unit also ensures that the boundary conditions at the wall<br />

were well matched and reproducible for both plates.<br />

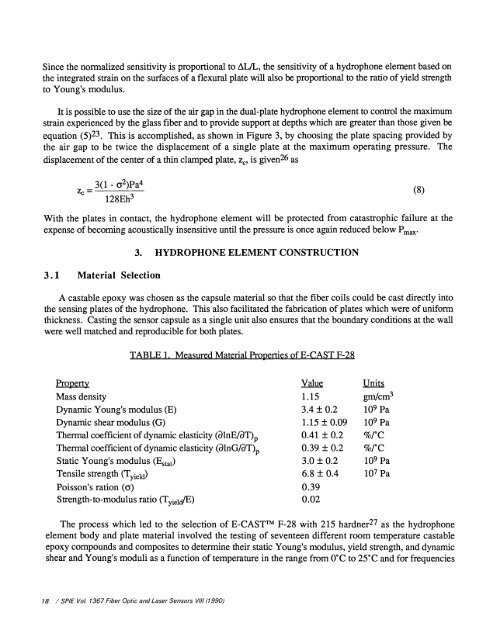

TABLE 1. Measured Material Properties <strong>of</strong> E-CAST F-28<br />

Property<br />

Mass density<br />

Dynamic Young's modulus (E)<br />

Dynamic shear modulus (G)<br />

Thermal coefficient <strong>of</strong> dynamic elasticity (lnE/aT)<br />

Thermal coefficient <strong>of</strong> dynamic elasticity ()lnG/aT)<br />

Static Young's modulus (Estat)<br />

Tensile strength (Tyjeld)<br />

Poisson's ration ()<br />

Strength-to-modulusratio (TyjeidE)<br />

Value<br />

1.15<br />

3.4 0.2<br />

1.15 0.09<br />

0.41 0.2<br />

0.39 0.2<br />

3.0 0.2<br />

6.8 0.4<br />

0.39<br />

0.02<br />

Units<br />

gm/cm3<br />

iO Pa<br />

10 Pa<br />

%/°C<br />

%/°C<br />

10 Pa<br />

10 Pa<br />

The process which led to the selection <strong>of</strong> E-CAST F-28 with 215 hardner27 as the hydrophone<br />

element body and plate material involved the testing <strong>of</strong> seventeen different room temperature castable<br />

epoxy compounds and composites to determine their static Young's modulus, yield strength, and dynamic<br />

shear and Young's moduli as a function <strong>of</strong> temperature in the range from 0°C to 25°C and for frequencies<br />

18 / SPIE Vol. 1367 <strong>Fiber</strong> <strong>Optic</strong> and Laser Sensors VIII (1990)