A European group of companies - Saria Bio-Industries AG & Co. KG

A European group of companies - Saria Bio-Industries AG & Co. KG

A European group of companies - Saria Bio-Industries AG & Co. KG

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Full remodelling <strong>of</strong> the<br />

Illzach plant (Mulhouse)<br />

13 million euros invested<br />

x<br />

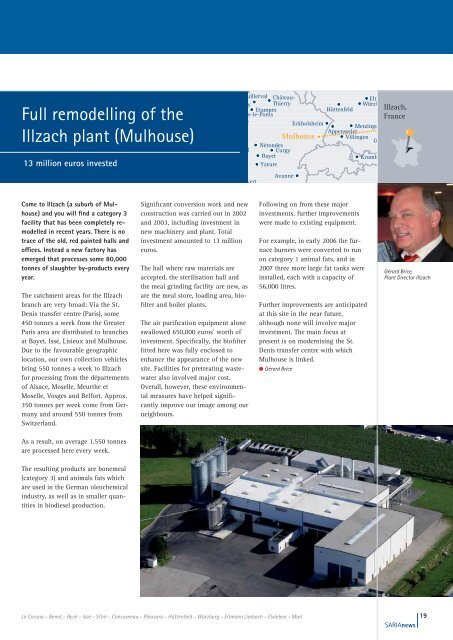

uillerval Château-<br />

Eltm<br />

y Thierry<br />

Würzb<br />

Etampes<br />

Hüttenfeld<br />

is-le-Ponts<br />

é<br />

Eckbolsheim<br />

Metzinge<br />

Appenweier<br />

Mulhouse<br />

Villingen<br />

O<br />

Nérondes<br />

l Curgy<br />

Bayet<br />

Krumb<br />

Yzeure<br />

vert<br />

Avanne<br />

Illzach,<br />

France<br />

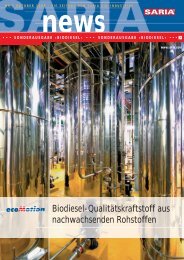

<strong>Co</strong>me to Illzach (a suburb <strong>of</strong> Mulhouse)<br />

and you will find a category 3<br />

facility that has been completely remodelled<br />

in recent years. There is no<br />

trace <strong>of</strong> the old, red painted halls and<br />

<strong>of</strong>fices. Instead a new factory has<br />

emerged that processes some 80,000<br />

tonnes <strong>of</strong> slaughter by-products every<br />

year.<br />

The catchment areas for the Illzach<br />

branch are very broad: Via the St.<br />

Denis transfer centre (Paris), some<br />

450 tonnes a week from the Greater<br />

Paris area are distributed to branches<br />

at Bayet, Issé, Lisieux and Mulhouse.<br />

Due to the favourable geographic<br />

location, our own collection vehicles<br />

bring 550 tonnes a week to Illzach<br />

for processing from the départements<br />

<strong>of</strong> Alsace, Moselle, Meurthe et<br />

Moselle, Vosges and Belfort. Approx.<br />

350 tonnes per week come from Germany<br />

and around 550 tonnes from<br />

Switzerland.<br />

Significant conversion work and new<br />

construction was carried out in 2002<br />

and 2003, including investment in<br />

new machinery and plant. Total<br />

investment amounted to 13 million<br />

euros.<br />

The hall where raw materials are<br />

accepted, the sterilisation hall and<br />

the meal grinding facility are new, as<br />

are the meal store, loading area, bi<strong>of</strong>ilter<br />

and boiler plants.<br />

The air purification equipment alone<br />

swallowed 650,000 euros’ worth <strong>of</strong><br />

investment. Specifically, the bi<strong>of</strong>ilter<br />

fitted here was fully enclosed to<br />

enhance the appearance <strong>of</strong> the new<br />

site. Facilities for pretreating wastewater<br />

also involved major cost.<br />

Overall, however, these environmental<br />

measures have helped significantly<br />

improve our image among our<br />

neighbours.<br />

Following on from these major<br />

investments, further improvements<br />

were made to existing equipment.<br />

For example, in early 2006 the furnace<br />

burners were converted to run<br />

on category 1 animal fats, and in<br />

2007 three more large fat tanks were<br />

installed, each with a capacity <strong>of</strong><br />

56,000 litres.<br />

Further improvements are anticipated<br />

at this site in the near future,<br />

although none will involve major<br />

investment. The main focus at<br />

present is on modernising the St.<br />

Denis transfer centre with which<br />

Mulhouse is linked.<br />

● Gérard Brice<br />

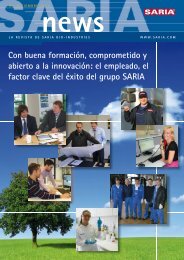

Gérard Brice,<br />

Plant Director Illzach<br />

As a result, on average 1,550 tonnes<br />

are processed here every week.<br />

The resulting products are bonemeal<br />

(category 3) and animals fats which<br />

are used in the German oleochemical<br />

industry, as well as in smaller quantities<br />

in biodiesel production.<br />

La <strong>Co</strong>runa – Benet – Rezé – Issé – Vitré – <strong>Co</strong>ncarneau – Plouvara – Hüttenfeld – Würzburg – Eltmann Limbach – Elxleben – Marl<br />

19<br />

SARIAnews