Malaysia - SETatWork - Sustainable Energy Technology at Work

Malaysia - SETatWork - Sustainable Energy Technology at Work

Malaysia - SETatWork - Sustainable Energy Technology at Work

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

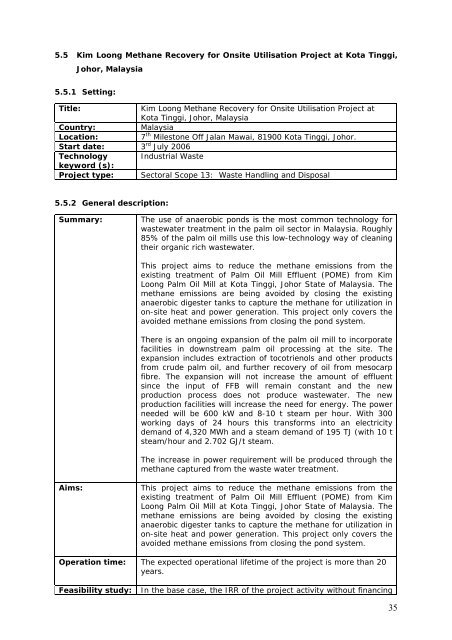

5.5 Kim Loong Methane Recovery for Onsite Utilis<strong>at</strong>ion Project <strong>at</strong> Kota Tinggi,<br />

Johor, <strong>Malaysia</strong><br />

5.5.1 Setting:<br />

Title:<br />

Kim Loong Methane Recovery for Onsite Utilis<strong>at</strong>ion Project <strong>at</strong><br />

Kota Tinggi, Johor, <strong>Malaysia</strong><br />

Country:<br />

<strong>Malaysia</strong><br />

Loc<strong>at</strong>ion:<br />

7 th Milestone Off Jalan Mawai, 81900 Kota Tinggi, Johor.<br />

Start d<strong>at</strong>e: 3 rd July 2006<br />

<strong>Technology</strong> Industrial Waste<br />

keyword (s):<br />

Project type: Sectoral Scope 13: Waste Handling and Disposal<br />

5.5.2 General description:<br />

Summary:<br />

The use of anaerobic ponds is the most common technology for<br />

wastew<strong>at</strong>er tre<strong>at</strong>ment in the palm oil sector in <strong>Malaysia</strong>. Roughly<br />

85% of the palm oil mills use this low-technology way of cleaning<br />

their organic rich wastew<strong>at</strong>er.<br />

This project aims to reduce the methane emissions from the<br />

existing tre<strong>at</strong>ment of Palm Oil Mill Effluent (POME) from Kim<br />

Loong Palm Oil Mill <strong>at</strong> Kota Tinggi, Johor St<strong>at</strong>e of <strong>Malaysia</strong>. The<br />

methane emissions are being avoided by closing the existing<br />

anaerobic digester tanks to capture the methane for utiliz<strong>at</strong>ion in<br />

on-site he<strong>at</strong> and power gener<strong>at</strong>ion. This project only covers the<br />

avoided methane emissions from closing the pond system.<br />

There is an ongoing expansion of the palm oil mill to incorpor<strong>at</strong>e<br />

facilities in downstream palm oil processing <strong>at</strong> the site. The<br />

expansion includes extraction of tocotrienols and other products<br />

from crude palm oil, and further recovery of oil from mesocarp<br />

fibre. The expansion will not increase the amount of effluent<br />

since the input of FFB will remain constant and the new<br />

production process does not produce wastew<strong>at</strong>er. The new<br />

production facilities will increase the need for energy. The power<br />

needed will be 600 kW and 8-10 t steam per hour. With 300<br />

working days of 24 hours this transforms into an electricity<br />

demand of 4,320 MWh and a steam demand of 195 TJ (with 10 t<br />

steam/hour and 2.702 GJ/t steam.<br />

The increase in power requirement will be produced through the<br />

methane captured from the waste w<strong>at</strong>er tre<strong>at</strong>ment.<br />

Aims:<br />

This project aims to reduce the methane emissions from the<br />

existing tre<strong>at</strong>ment of Palm Oil Mill Effluent (POME) from Kim<br />

Loong Palm Oil Mill <strong>at</strong> Kota Tinggi, Johor St<strong>at</strong>e of <strong>Malaysia</strong>. The<br />

methane emissions are being avoided by closing the existing<br />

anaerobic digester tanks to capture the methane for utiliz<strong>at</strong>ion in<br />

on-site he<strong>at</strong> and power gener<strong>at</strong>ion. This project only covers the<br />

avoided methane emissions from closing the pond system.<br />

Oper<strong>at</strong>ion time: The expected oper<strong>at</strong>ional lifetime of the project is more than 20<br />

years.<br />

Feasibility study:<br />

In the base case, the IRR of the project activity without financing<br />

35